A Combination Valve with Compensating Load Sensing Function of Oil Return Circuit

A load-sensitive, oil-return technology, applied in servo motor components, mechanical equipment, fluid pressure actuating devices, etc., can solve problems such as asynchronous work of multiple actuators, achieve high work efficiency and response performance, and improve efficiency , The effect of stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

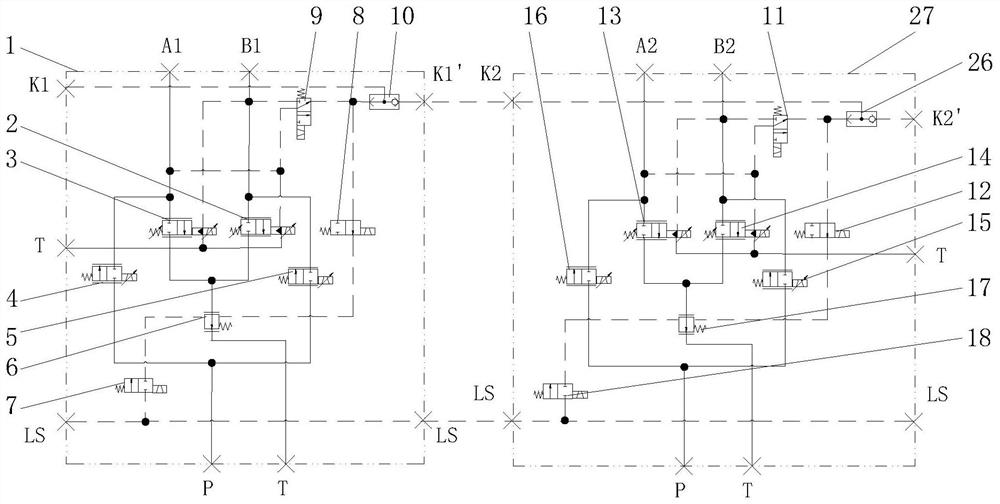

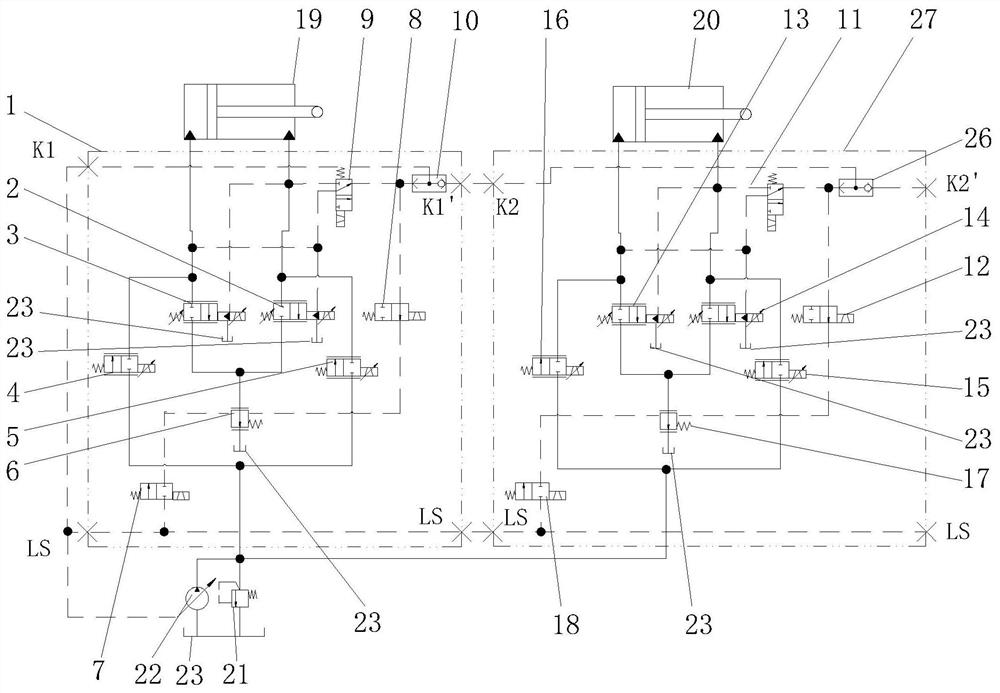

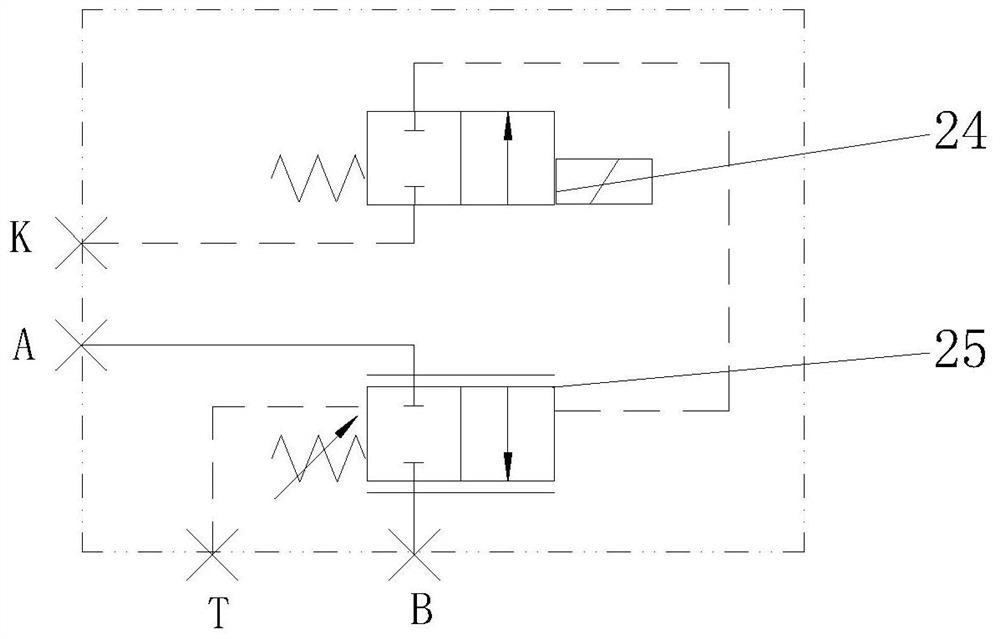

[0035] see Figure 1 to Figure 3, a combination valve with the function of compensating the load sensitivity of the return oil circuit, including a multi-connected valve group, a supply oil circuit P, an oil return circuit T, a load-sensitive oil circuit LS, and the multi-connected valve group shares a unified supply oil circuit P, return oil circuit The oil circuit T and the load-sensing oil circuit LS, each valve group has an output oil port An and an output oil port Bn connected to the actuator, and the multi-connected valve group includes a first valve group 1 and a second valve group. Group 27, the third valve group, ..., the Nth valve grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com