Hydraulic fracturing method for reducing cracking pressure through fixed-point perforation

A technology of hydraulic fracturing and formation fracture pressure, which is applied in the field of oil and gas field exploration and development, can solve the problems of inconspicuous effect, cumbersome construction procedures, and high operating costs, and achieve the effects of easy on-site promotion, increased construction procedures, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

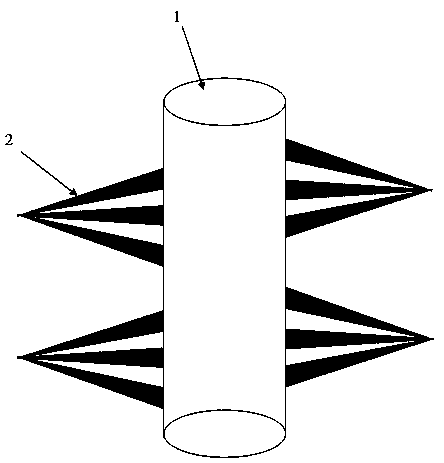

[0021] In order to overcome the existing problems of insignificant effect of reducing broken pressure, cumbersome construction procedures and high operating costs, the present invention provides such figure 1 A hydraulic fracturing method for fixed-point perforation to reduce the breaking pressure is shown. The present invention uses perforating guns to carry out multiple groups of fixed-point perforations. Each group of perforating charges is concentrated at one point, and each group of perforating charges is A stress fracture zone is formed, which cooperates with the low-viscosity liquid to break the pressure, thereby greatly reducing the fracture pressure of the formation. The method is simple to operate, does not increase the construction process and operation cost, can effectively reduce formation fracture pressure, is convenient for on-site promotion, and is suitable for hydraulic fracturing operations of high-hardness and high-fracture-pressure reservoirs.

[0022] A hy...

Embodiment 2

[0026] Based on Embodiment 1, in this embodiment, the multiple groups of fixed-point perforations are fire perforations, and the number of perforations in each group is 3-4.

[0027] For the multiple groups of fixed-point perforations, each group of perforations has a perforation thickness of 0.25-0.33m.

[0028] The hydraulic fracturing of the reservoir is to use low-viscosity fracturing fluid to break the pressure, and then perform subsequent fracturing procedures. The subsequent fracturing procedure is an existing conventional fracturing procedure. No further description will be made in the present invention.

[0029] The low-viscosity fracturing fluid is active water or slick water, the viscosity of which is lower than 2mPa.s.

[0030] In the present invention, the perforating gun performs multiple sets of fixed-point perforation, and each set of perforating bullets is concentrated at one point. Each set of perforating bullets forms a stress fracture zone in the formatio...

Embodiment 3

[0036] On the basis of Example 2, in this example, cable transmission is used to carry out fixed-point perforation on the stratum. There are 3; hydraulic fracturing is carried out afterwards, and hydraulic fracturing uses low-viscosity fracturing fluid to break pressure. In this embodiment, the low-viscosity fracturing fluid uses active water, and active water is used as a pre-fluid to break pressure on the formation. The active water viscosity range is 1.3mPa.s, and the component distribution ratio is: 0.5 part of clay stabilizer, 0.5 part of drainage aid, and the rest is water. Hydraulic fracturing uses low-viscosity fracturing fluid to break pressure, and other fracturing procedures are the same as conventional fracturing processes. Hydraulic fracturing will not be described in detail in this disclosure. After the low-viscosity fracturing fluid breaks the pressure, the fracture pressure of hydraulic fracturing is effectively reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com