Recyclable sound insulation unit convenient to disassemble

A convenient disassembly, square technology, applied in the direction of sound insulation, building components, construction, etc., can solve the problems of inconvenient disassembly, damage, unfavorable reuse, etc., and achieve the effect of convenient operation and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

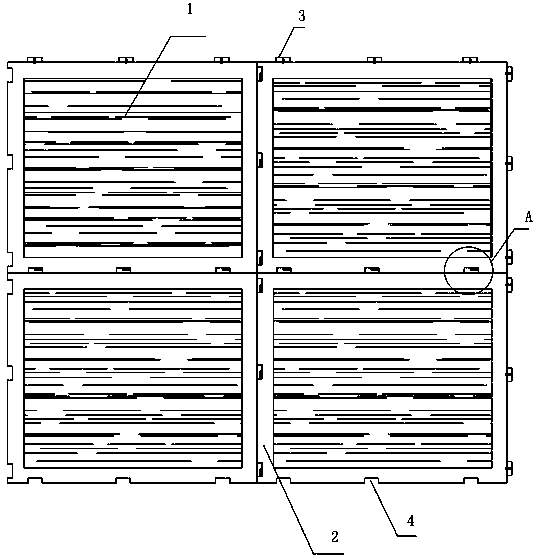

[0020] A reusable sound insulation unit 1 that is easy to disassemble includes a square frame, a panel, and a back panel. The panel and the back panel are fixed in the square outer frame by bolts, and the accommodation space between the panel and the back panel is filled with sound-insulating materials.

[0021] The upper and lower frames of the square outer frame are respectively provided with a connection structure A3 and a connection structure B4. The left and right borders of the square outer frame are respectively provided with a connecting structure A3 and a connecting structure B4.

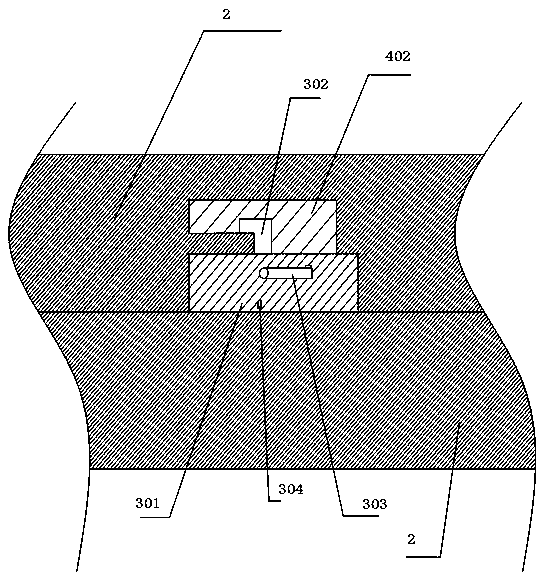

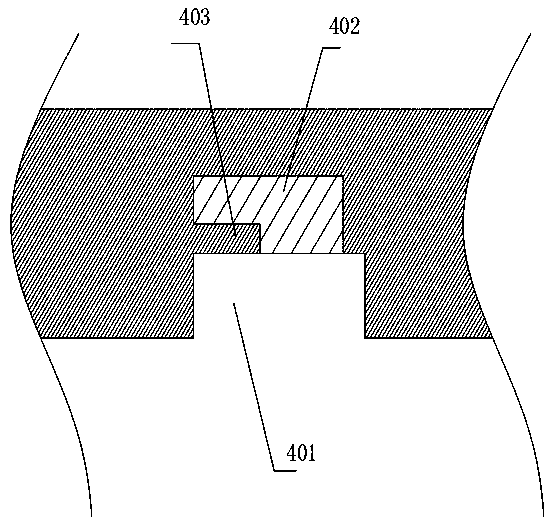

[0022] like figure 1 The connection structure A3 and the connection structure B4 on the square outer frame of the sound insulation unit 1 shown are respectively used for corresponding connection with the connection structure B4 and connection structure A3 of another sound insulation unit 1 .

[0023] Specifically, each frame is provided with a number of connection structures A3 that are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com