Switching device, garment steamer and switch control device

A technology of a switch device and a garment steamer, which is applied in the field of garment steamers and can solve problems such as the lack of safety protection functions of the garment steamer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

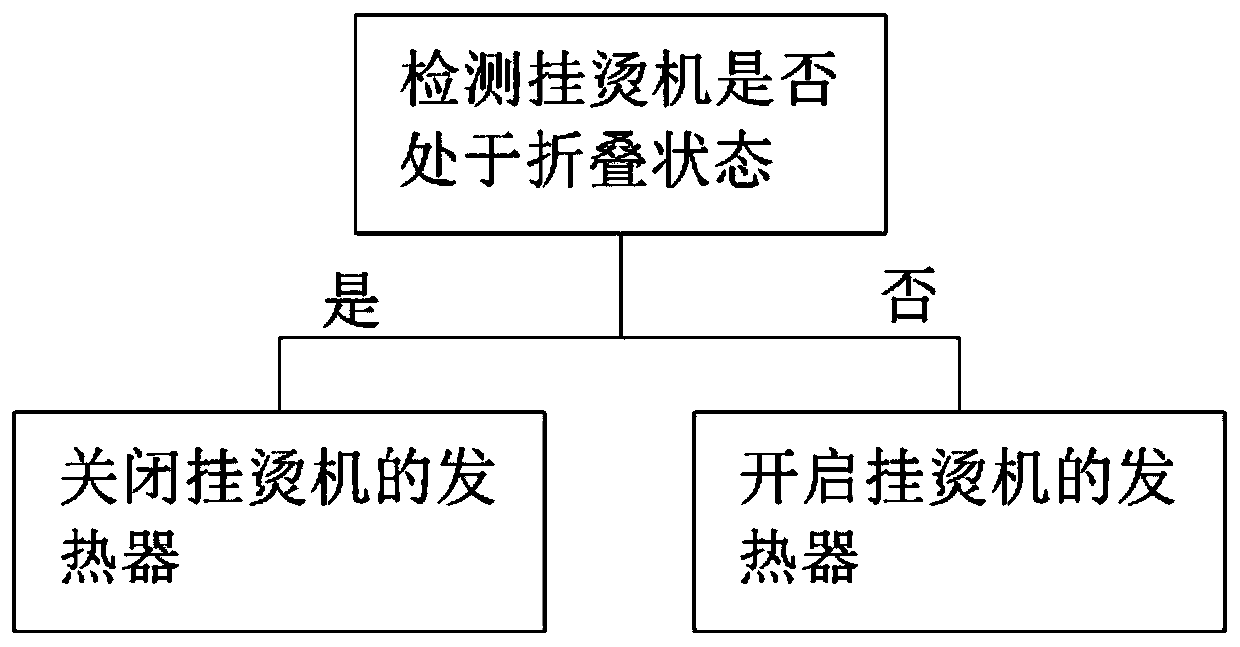

Problems solved by technology

Method used

Image

Examples

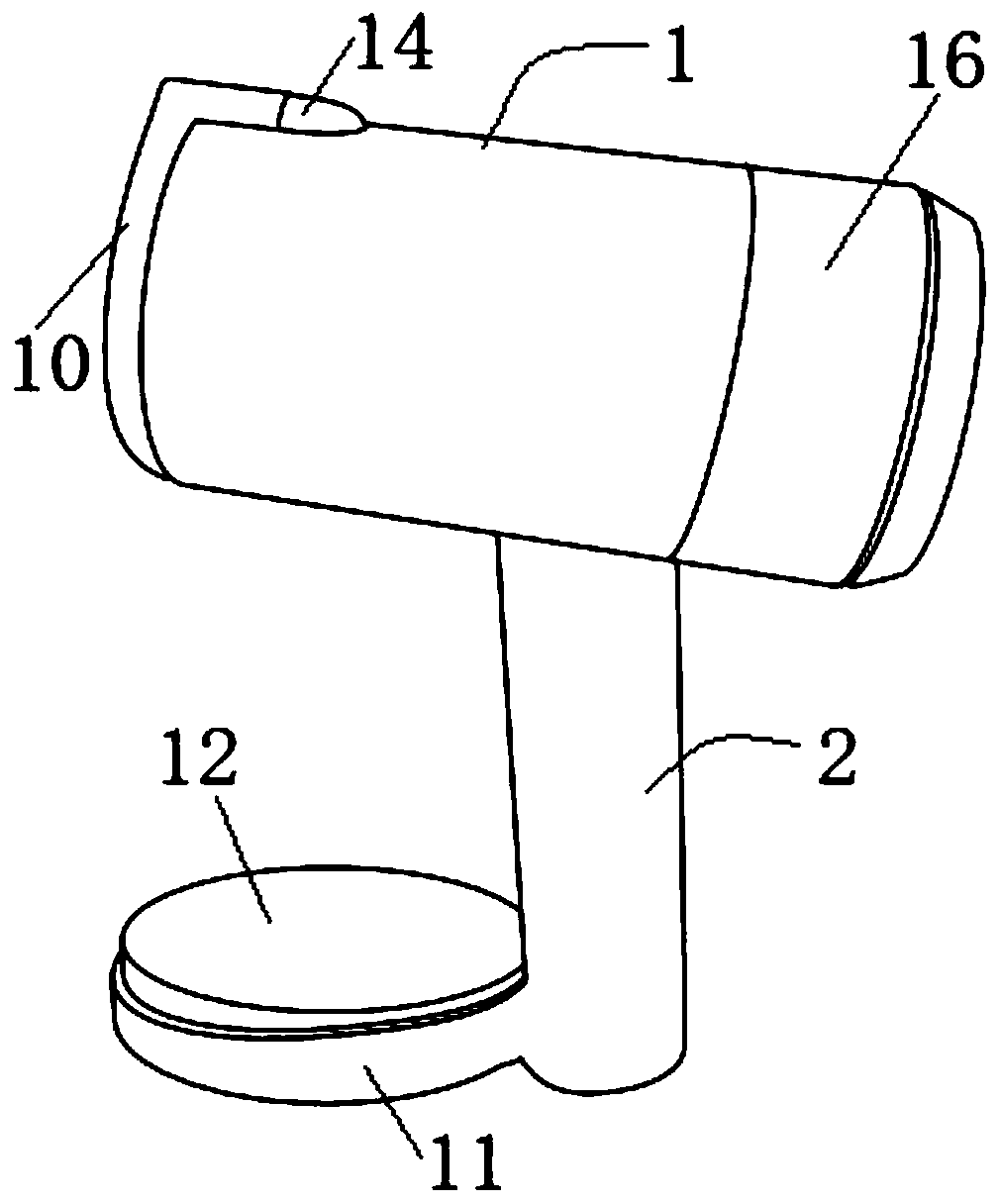

Embodiment 1

[0043] In laundry shops, clothing stores and other shops, merchants use garment ironing machines to iron clothes so that the wrinkled places become smooth and beautiful.

[0044] After the garment steamer is powered on with water, the internal heater will heat the water, so that the normal temperature water will be vaporized into high-temperature and high-pressure water vapor, and then the hot water vapor will be released through the catheter and nozzle. During use, the user only needs to spray water vapor at the creases of the clothes, and press or stretch through the creases to achieve the purpose of flattening the clothes.

[0045] Because the garment steamer is easy to operate, more and more families now purchase the garment steamer for use at home and while traveling. With the popularity of garment ironing machines, its safety has become more and more important.

[0046] The garment steamer will generate a very high temperature when it is working, and the heater can gene...

Embodiment 2

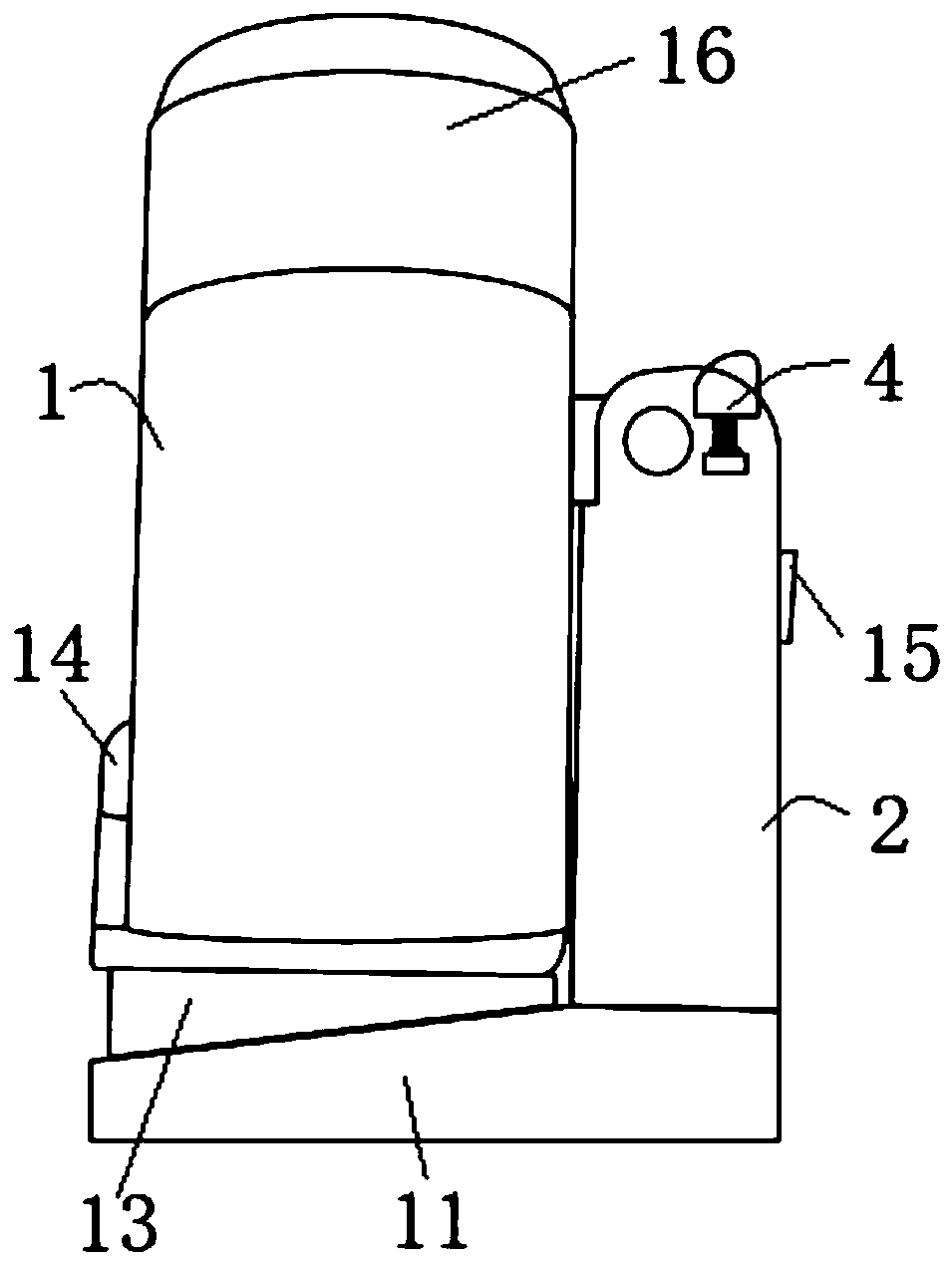

[0103] The difference between this embodiment and the first embodiment is that the detection module 5 adopts an electronic detection unit.

[0104] Compared with the mechanical detection unit, the electronic detection unit is smaller and more intelligent.

[0105] In this embodiment, the electronic detection unit may adopt a proximity sensor.

[0106] There are many kinds of receiving sensors, for example, inductive proximity sensors, capacitive proximity sensors, photoelectric sensors, Hall sensors and so on. During the manufacturing process, an appropriate type of receiving sensor can be selected according to actual needs.

[0107] In addition to the proximity detection module 5, the electronic detection unit can also use an angle sensor.

[0108] The angle sensor can be installed on the handle 2, and can be used to detect the relative angle between the main body 1 and the handle 2, so as to judge whether the garment steamer is in a folded state.

[0109] In order to coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com