High-density warp-knitted suede imitated non-woven microfiber leather fabric and production method thereof

A production method and technology of suede, applied in the field of textiles, can solve the problems of not having the performance of microfiber leather, can not be used for mobile phone cases and iPad protective cases, etc., and achieve the effects of large shrinkage, reduction of defects, and increase of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The production method of the high-density warp-knitted suede imitation non-woven microfiber leather fabric of this embodiment 1 may further comprise the steps:

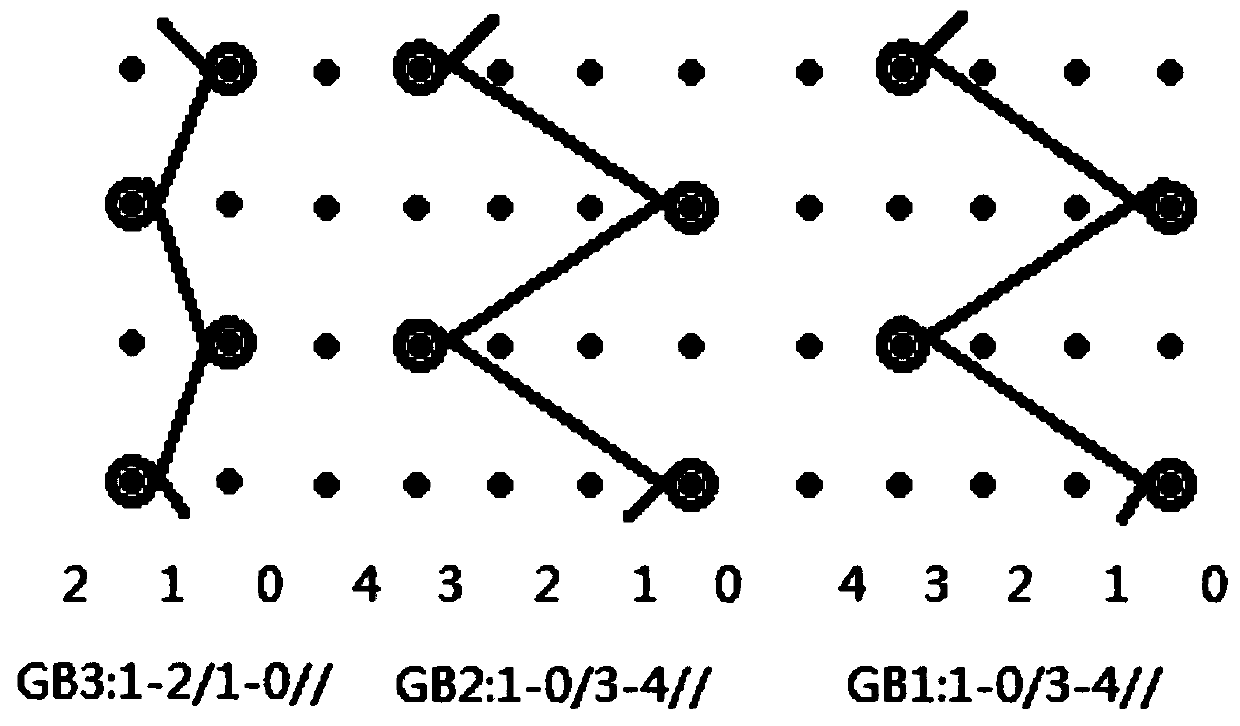

[0024] First of all, using 88dtex / 36f sea-island composite yarn and FDY 30D / 12F polyester high-shrinkage yarn as raw materials, three bars are used for weaving on the E32 high-speed warp knitting machine. The first bar is fully covered with 88dtex / 36f sea-island composite yarn. 1-0 / 3-4 / / laid yarn weaving, the second bar is fully threaded FDY 30D / 12F polyester high-shrinkage yarn, 1-0 / 3-4 / / laid yarn weaving, the third bar is fully threaded FDY 30D / 12F polyester high-shrinkage yarn, woven with 1-2 / 1-0 / / lay yarn;

[0025] Then, the woven fabric is sequentially refined, opened, washed in open width, pre-dried, napped, sanded, dyed, dried and shaped, napped, sanded, finalized, inspected, and packaged to obtain high-density warp-knitted suede. Velvet imitation non-woven microfiber leather fabric.

[0026] The refin...

Embodiment 2

[0032] The high-density warp-knitted suede of this embodiment 2 imitates the production method of non-woven superfiber leather fabric, comprises the following steps:

[0033] Firstly, using 105D / 36F*37 sea-island composite yarn and FDY 30D / 12F polyester high-shrinkage yarn as raw materials, three bars are used for weaving on the E32 high-speed warp knitting machine, and the first bar is fully covered with 105D / 36F*37 island Composite yarn, woven with 1-0 / 3-4 / / lay-up yarn, the second bar is fully covered with FDY 30D / 12F polyester high-shrinkage yarn, woven with 1-0 / 3-4 / / lay-up yarn, the third The bar is full of FDY 30D / 12F polyester high-shrinkage yarn, woven with 1-2 / 1-0 / / lay yarn;

[0034] Then, the woven fabric is sequentially refined, opened, washed in open width, pre-dried, napped, sanded, dyed, dried and shaped, napped, sanded, finalized, inspected, and packaged to obtain high-density warp-knitted suede. Velvet imitation non-woven microfiber leather fabric.

[0035] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com