A kind of preparation method of refractory metal molybdenum protective film resistant to liquid lead and bismuth corrosion

A liquid lead-bismuth alloy, refractory metal technology, applied in the direction of metal material coating process, can solve the problems of corrosion, affecting material properties, poor bonding force, etc., and achieve the effect of good stability and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Experimental preparation process for in-situ formation of protective film of refractory metal molybdenum in liquid lead-bismuth alloy:

[0071] The refractory metal molybdenum used in this example is prepared by powder metallurgy, and its basic raw material is generally molybdenite (MoS 2 ). Molybdenum trioxide mixed with impurities can be obtained by roasting molybdenite, and then dissolving molybdenum trioxide in ammonia water to obtain ammonium paramolybdate (NH 4 ) 6 Mo 7 o 24 ) solution and filter the slag. Extract ammonium paramolybdate salt from the solution and roast at about 500°C to decompose to generate high-purity molybdenum trioxide. Molybdenum trioxide is reduced to molybdenum trioxide with hydrogen to obtain pure molybdenum powder, which is cold pressed and sintered to obtain a rod with a diameter of 90 cm, and finally extruded into a rod with a diameter of 7 mm.

[0072] The specific chemical reaction equation of the prepared molybdenum powder is a...

Embodiment 2

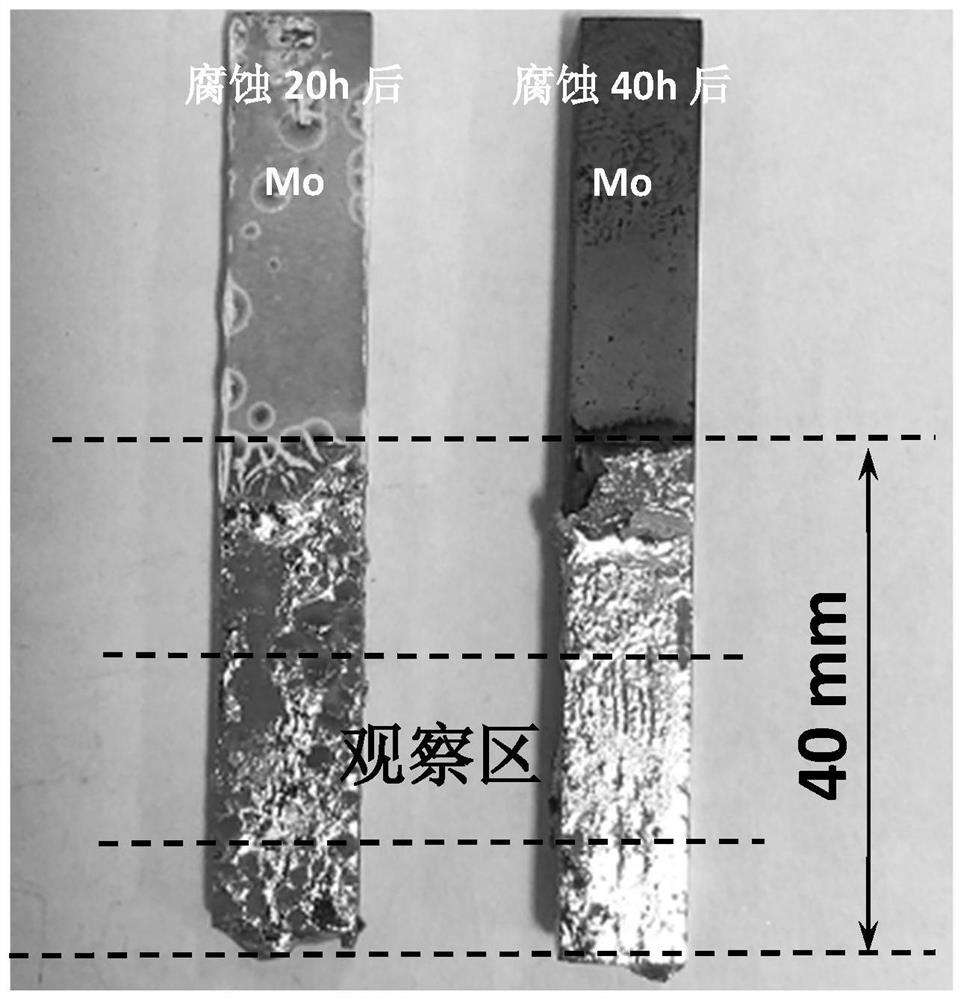

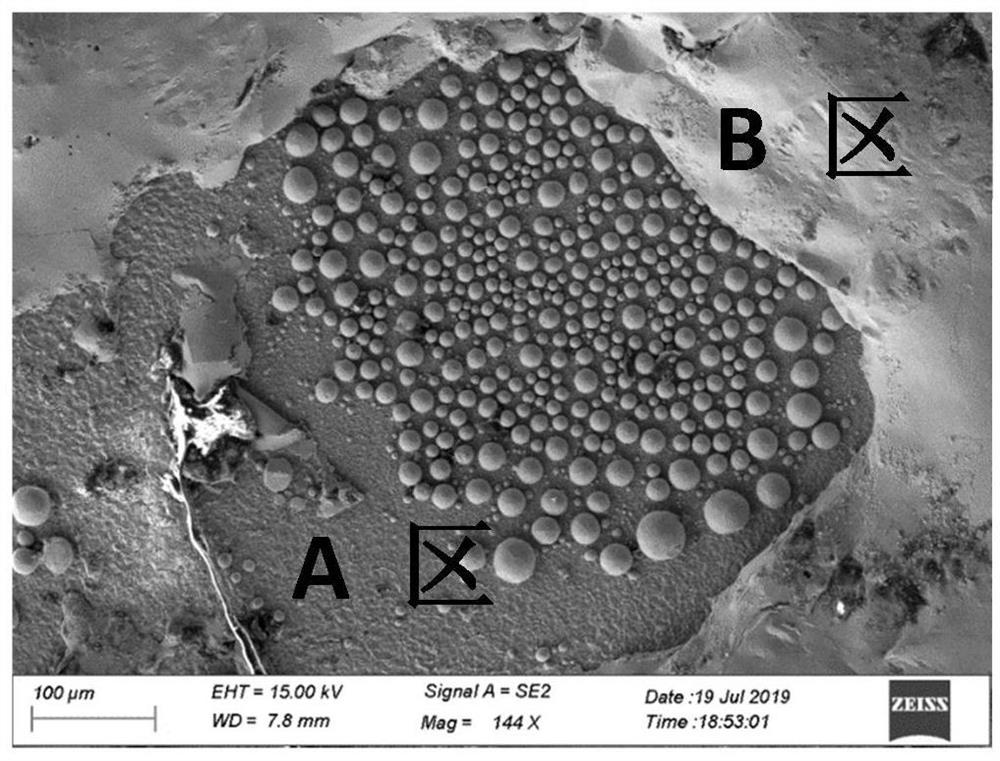

[0090] 1) Prepared by powder metallurgy method Molybdenum rods, and cut into two experimental samples of 3x6x50mm, remove the surface oxide skin and then carry out stress relief annealing at 900 ° C for 50 minutes; after grinding the samples with 240#, 400#, 800#, 1200#, 2000# water sandpaper , remove the scratches on the surface of the sample with a polishing cloth made of woolen material and a 2.5 μm diamond polishing agent, and finally clean it ultrasonically with alcohol for 5 minutes and dry it;

[0091] Cut the large block of lead-bismuth alloy into small pieces by cutting machine, weigh 400g to be used as corrosion medium, ultrasonically clean with alcohol for half an hour and dry;

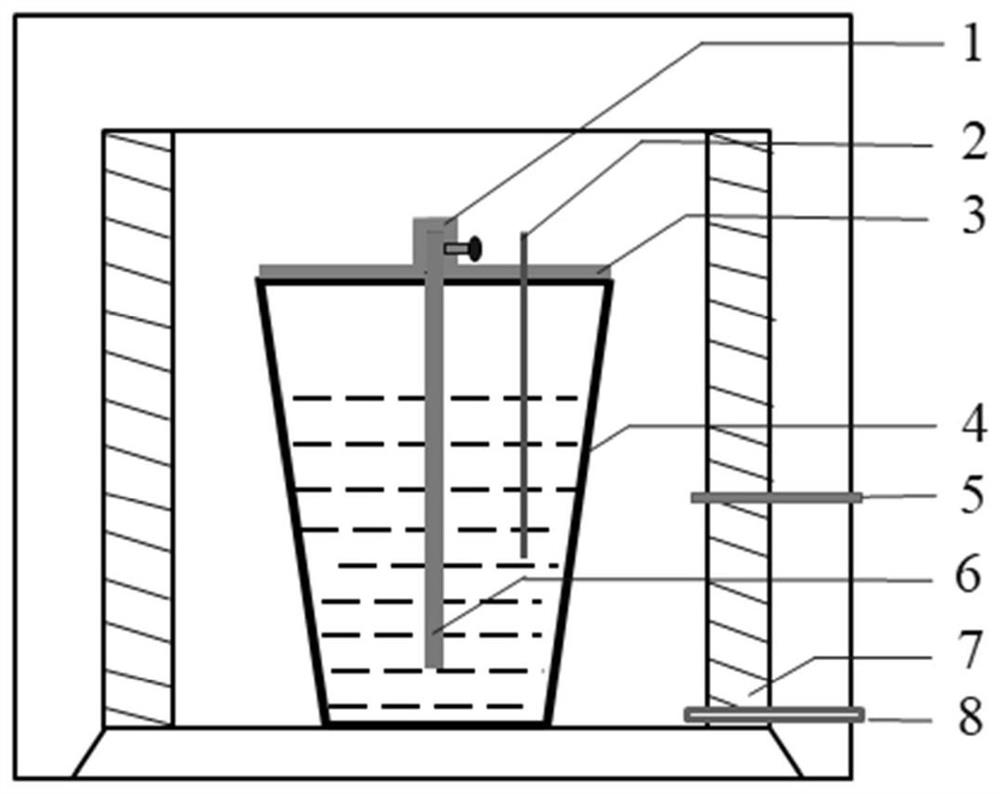

[0092] 2) Put the weighed lead-bismuth alloy into a 50ml high-purity alumina crucible, and place it together in an atmosphere muffle furnace with a furnace temperature of 590°C for 20 minutes to completely melt the lead-bismuth alloy;

[0093] 3) Insert the sample into a crucible filled w...

Embodiment 3

[0096] 1) Prepared by powder metallurgy method Molybdenum rods, and cut into two experimental samples of 3x6x50mm, remove the surface oxide skin and then carry out stress relief annealing at 850 ° C for 60 minutes; after grinding the samples with 240#, 400#, 800#, 1200#, 2000# water sandpaper , remove the scratches on the surface of the sample with a polishing cloth made of woolen material and a 2.5 μm diamond polishing agent, and finally clean it ultrasonically with alcohol for 5 minutes and dry it;

[0097] Cut the large block of lead-bismuth alloy into small pieces by cutting machine, weigh 400g to be used as corrosion medium, ultrasonically clean with alcohol for half an hour and dry;

[0098] 2) Put the weighed lead-bismuth alloy into a 50ml high-purity alumina crucible, and place it together in an atmosphere muffle furnace with a furnace temperature of 600°C for 20 minutes to completely melt the lead-bismuth alloy;

[0099] 3) Insert the sample into a crucible filled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com