Method for preparing benzoin in micro-reaction device

A micro-reaction device and benzoin technology, applied in the field of chemical reaction, can solve the problems of long production cycle, large amount of catalyst, environmental pollution and the like of batch reactor type reactor, achieve high-efficiency heat and mass transfer capability, clean reaction, reduce effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

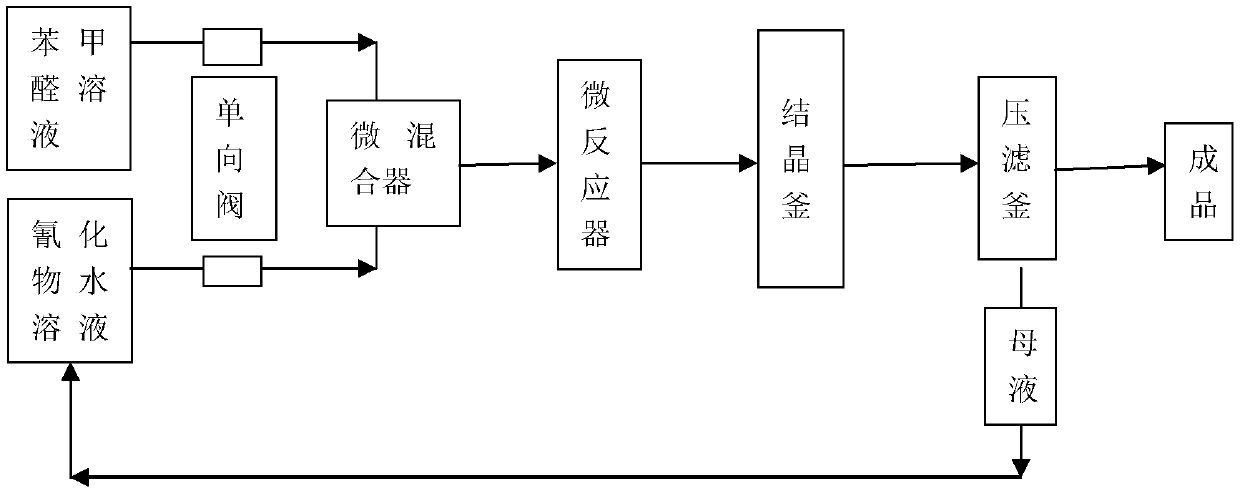

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of benzoin

[0024] Dissolve 100g of benzaldehyde in 40ml of methanol, mix well, pump into the micro-mixer, and at the same time pump 10ml of 5% sodium cyanide aqueous solution into the micro-mixer, adjust the flow rate of benzaldehyde solution to 2ml / min, adjust the flow rate of sodium cyanide aqueous solution The reaction time is 0.13ml / min, stay in the micro-mixer for 6s, enter the micro-reactor for reaction, the reaction time is 10min, heat to 50 degrees, sample for gas phase analysis, the reaction selectivity is 98.9%. The reacted material was cooled and crystallized, filtered and dried to obtain 97 g of the product, and the product yield was 97%. The mother liquor is recovered to the cyanide storage kettle for recycling.

Embodiment 2

[0025] Embodiment 2: the preparation of benzoin

[0026] Dissolve 100g of benzaldehyde in 40ml of methanol, mix well, pump into the micro-mixer, and at the same time pump 20ml of 1% sodium cyanide aqueous solution into the micro-mixer, adjust the flow rate of benzaldehyde solution to 2ml / min, adjust the flow rate of sodium cyanide aqueous solution 0.29ml / min, stay in the micro-mixer for 6s, enter the micro-reactor for reaction, the reaction time is 20min, the reaction temperature is 60 degrees, sampling for gas phase analysis, the reaction selectivity is 98.3%. The reacted material was cooled and crystallized, filtered and dried to obtain 96.5 g of the product, and the product yield was 96.5%.

Embodiment 3

[0027] Embodiment 3: the preparation of benzoin

[0028] Dissolve 100g of benzaldehyde in 50ml of methanol, mix well, pump into the micro-mixer, and at the same time pump 5ml of 10% sodium cyanide aqueous solution into the micro-mixer, adjust the flow rate of benzaldehyde solution to 2ml / min, adjust the flow rate of sodium cyanide aqueous solution 0.06ml / min, stay in the micro-mixer for 5s, enter the micro-reactor for reaction, the reaction time is 20min, the reaction temperature is 45 degrees, sampling for gas phase analysis, the reaction selectivity is 98.9%. The reacted material was cooled and crystallized, filtered and dried to obtain 97.5 g of the product, and the product yield was 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com