Zirconia ceramic slurry for micro-flow extrusion molding and its preparation method and application

A zirconia ceramic, extrusion molding technology, applied in ceramic molding machines, manufacturing tools, pharmaceutical formulations, etc., can solve the problems of liquid phase migration, insufficient strength of extruded filaments, etc. The effect of not taking into account the rheology and strengthening the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A method for preparing zirconia ceramic slurry for microfluidic extrusion molding, wherein: The preparation method comprises the following steps:

[0049] According to the above ratio, ceramic powder, sodium polyacrylate dispersion agent and MRH-070 hyin epoxy resin toughening agent were weighed and mixed, adding a lubricant taken according to the proportion, adding pH adjuster to adjust the pH value to 8 ~ 9; the above mixed liquid was magnetically stirred for 30 ~ 40min, stirred and placed in the TJ series planetary ball mill tank, keeping the ball mill speed of 1000 ~ 1200r / min ball mill 8 ~ 12h, After standing for 2h, a zirconia ceramic paste for microflow extrusion was prepared.

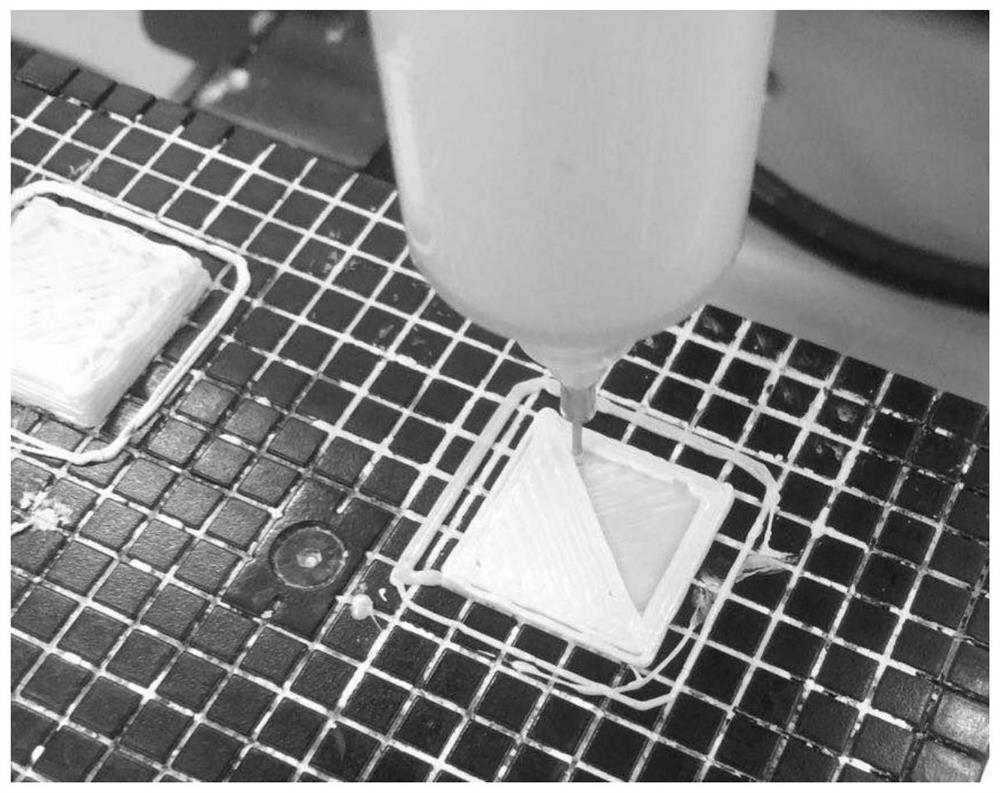

[0050] An application of zirconia ceramic paste for microfluidic extrusion molding, characterized by: consisting of the following steps:

[0051] The above obtained zirconia ceramic paste for microfluidic extrusion molding is injected into the plunger barrel of the three-dimensional molding...

Embodiment 1

[0053] The zirconia ceramic paste used in the present embodiment for the microfluidic extrusion molding process, the composition of the ceramic powder used and the mass fraction of each component are shown in Table 1, the components of the zirconia ceramic slurry used and the mass fraction of each component are shown in Table 2.

[0054] Table 1 Composition of ceramic powder (mass fraction,%)

[0055] Ceramic powder alumina Titanium oxide zirconia Quality score 5% 3% 92%

[0056] Table 2 Composition of zirconia ceramic paste (mass fraction, %)

[0057] Zirconia ceramic paste Ceramic powder lubricant Sodium polyacrylate Hine epoxy resin Quality score 68wt% 20wt% 4.08wt% 8.16wt%

[0058] Alumina and titanium oxide are nanoscale ceramic powders, sodium polyacrylate diluted in aqueous solution, formulated into an aqueous solution with a mass fraction of 50wt%, and its molecular mass is 3000~5000;

[0059] Zirconia is nano zirconia powder ...

Embodiment 2

[0098] The zirconia ceramic paste used in the microfluidic extrusion molding process, the composition of the ceramic powder used and the mass fraction of each component are shown in Table 5, the components of the zirconia ceramic slurry used and the mass fraction of each component are shown in Table 6.

[0099] Table 5 Composition of ceramic powder (mass fraction,%)

[0100] Ceramic powder alumina Titanium oxide zirconia Quality score 3% 4% 93%

[0101] Table 6 Composition of zirconia ceramic paste (mass fraction, %)

[0102] Zirconia ceramic paste Ceramic powder lubricant Sodium polyacrylate Hine epoxy resin Quality score 70wt% 20wt% 3.5wt% 6.5wt%

[0103] Other steps are the same as in Example 1, the resulting product is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com