Carbon fiber honeycomb core material node cementing method

A technology of honeycomb core material and carbon fiber sheet, applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of core mold demolding difficulty and other problems, reduce the number of molds, avoid demoulding difficulties, and uniform pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

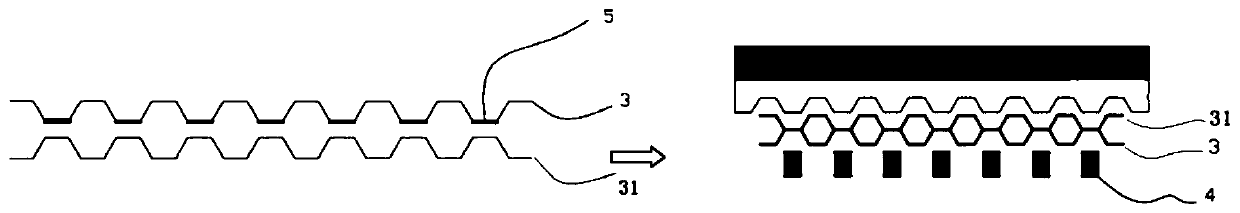

[0026] Adopt the method of the present invention to carry out the step of bonding carbon fiber honeycomb core material node as follows:

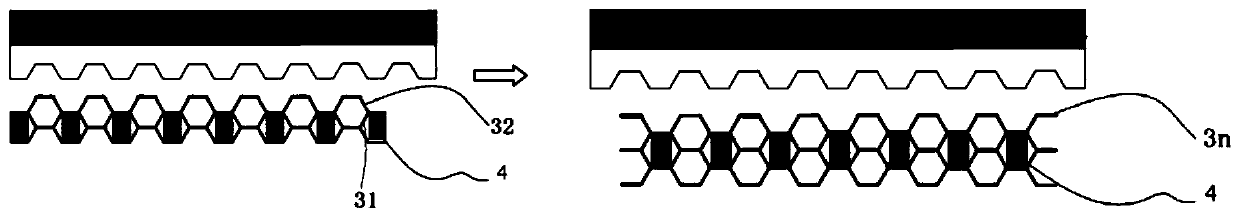

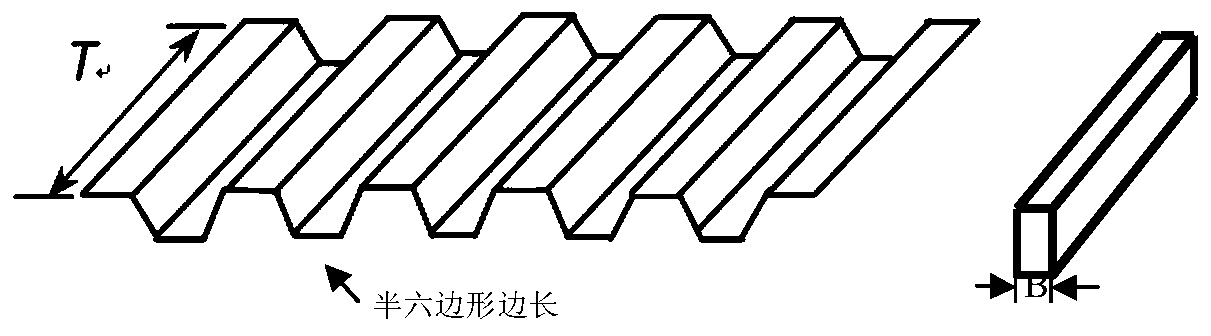

[0027] Step 1. Choose a number of semi-hexagonal carbon fiber sheets with a side length of 4.5mm made of AVIC Composite Material cf3052 / 5224 prepreg, T=100mm, on the outer surface of the first layer of semi-hexagonal carbon fiber sheet 3 The epoxy resin adhesive 5 produced by Heilongjiang Petrochemical Institute is evenly applied to the node positions on the same horizontal plane, and the solid content of the glue is 20%-50%. Combine the first layer of semi-hexagonal carbon fiber sheet 3 with the second layer of semi-hexagonal carbon fiber sheet 31, support the pressure rod 4 at the joint of the inner surface of the first layer of semi-hexagonal carbon fiber sheet 3, add The compression rod 4 is a regular hexagonal prism with a side length B of 4.0mm. Set a mold at the joint of the inner surface of the second layer of semi-hexagonal carbon ...

Embodiment 2

[0032] Adopt the method of the present invention to carry out the step of bonding carbon fiber honeycomb core material node as follows:

[0033] Step 1. Choose a number of semi-hexagonal carbon fiber sheets with a side length of 5.0mm made of polyimide prepreg produced by AVIC Composite Materials. On the same outer surface of the first layer of semi-hexagonal carbon fiber sheet 3 Evenly smear the polyimide adhesive 5 produced by Heilongjiang Petrochemical Institute on the joint positions of the horizontal plane, and the solid content of the glue is 20%-40%. Combine the first layer of semi-hexagonal carbon fiber sheet 3 with the second layer of semi-hexagonal carbon fiber sheet 31, support the pressure rod 4 at the joint of the inner surface of the first layer of semi-hexagonal carbon fiber sheet 3, add The compression rod 4 is a regular hexagonal prism with a side length of 4.0 mm. Set a mold at the joint of the inner surface of the second layer of semi-hexagonal carbon fiber...

Embodiment 3

[0038] Step 1. Select ACTECH produced by AVIC Composites @A number of semi-hexagonal carbon fiber sheets with a side length of 5.0mm made of 1201 / ccf300 carbon fiber plain fabric prepreg are evenly spread on the nodes of the same horizontal plane on the outer surface of the first layer of semi-hexagonal carbon fiber sheet 3 The fast-curing adhesive 5 produced by Heilongjiang Petrochemical Institute is a cyanate ester system, and the solid content of the glue is 20%-50%. Combine the first layer of semi-hexagonal carbon fiber sheet 3 with the second layer of semi-hexagonal carbon fiber sheet 31, support the pressure rod 4 at the joint of the inner surface of the first layer of semi-hexagonal carbon fiber sheet 3, add Depression bar 4 is square, and side length is 4.4mm. Set a mold at the joint of the inner surface of the second layer of semi-hexagonal carbon fiber sheet 31, and pre-bond it by heating and pressing. The bonding pressure is 0.1Mpa±0.05Mpa, the temperature is 160°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com