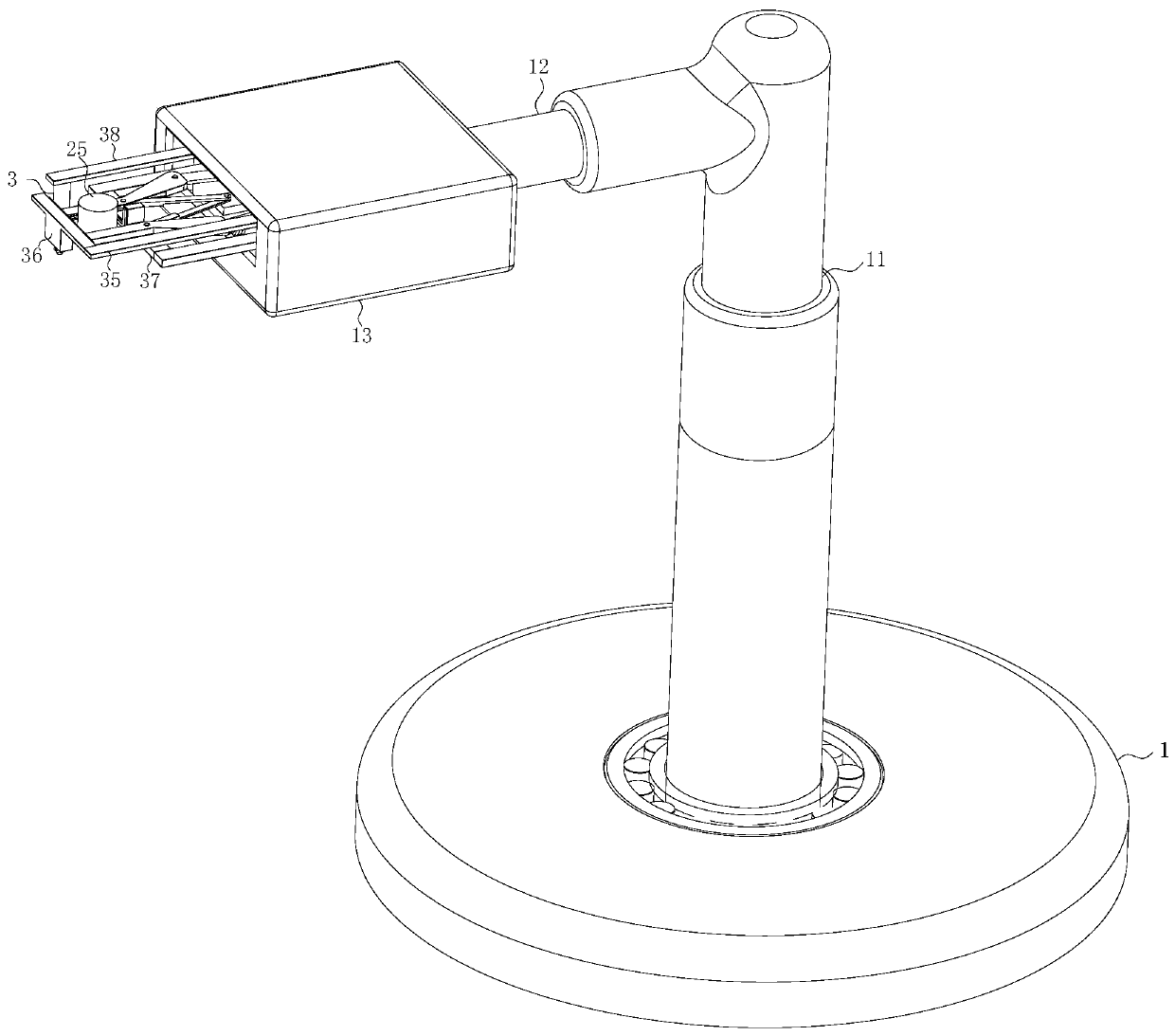

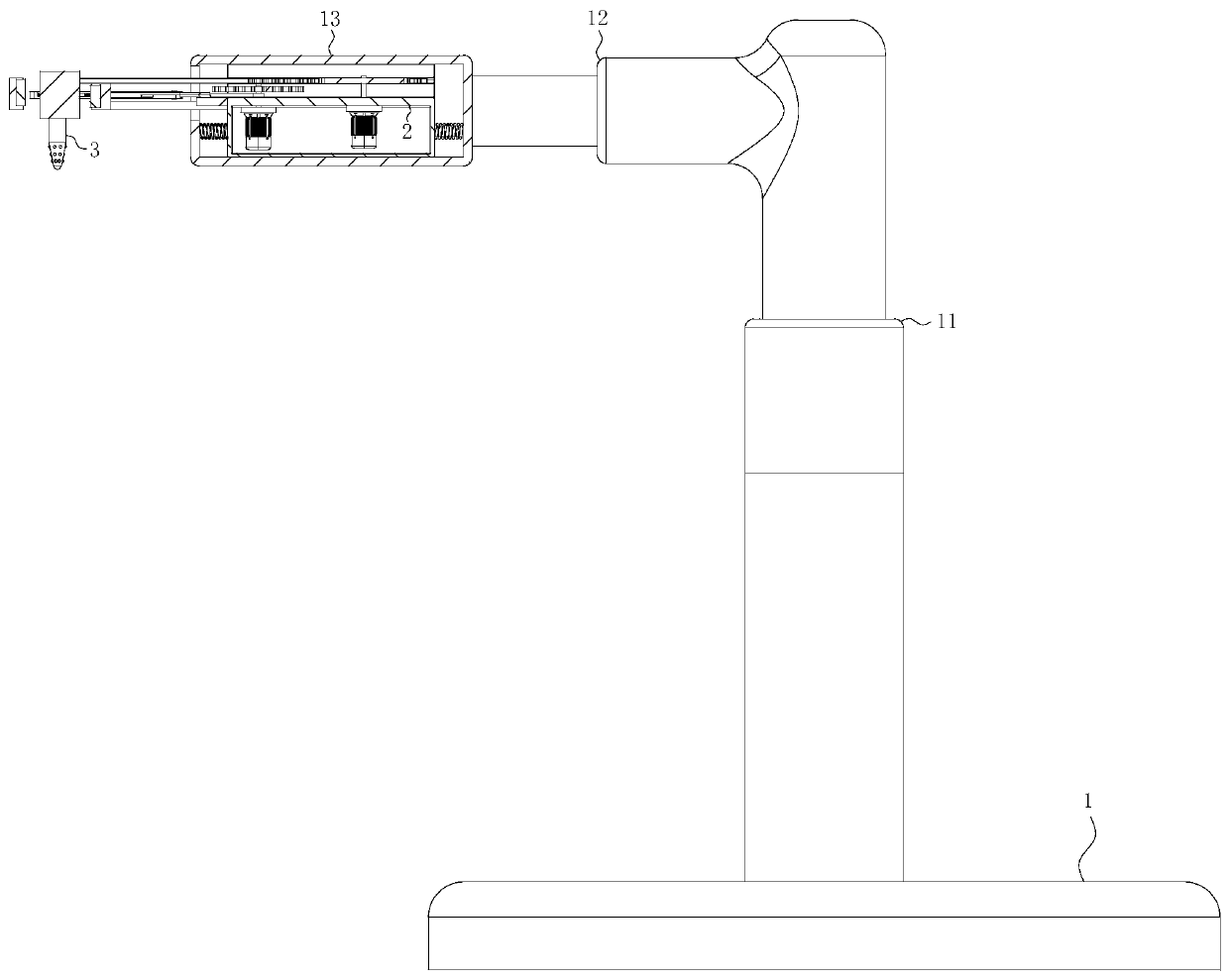

Robot carrying gripper capable of realizing accurate positioning of workpiece

A precise positioning and robot technology, applied in the field of manipulators, can solve the problems of unbalanced clamping force, no positioning pin insertion positioning, poor batch processing of products, etc., to improve the yield rate and ensure high-precision positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

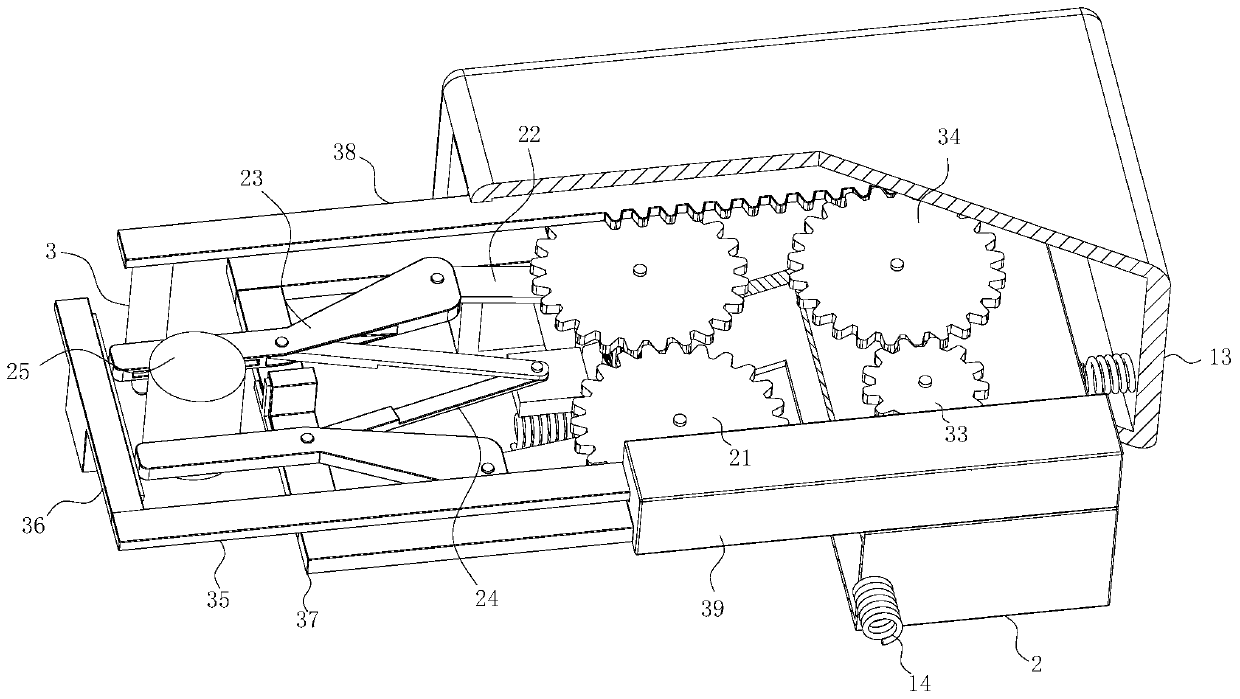

[0025] As an embodiment of the present invention, the power box 2 is slidably connected to the fixed shell 13; the inside of the first cavity is fixedly connected with a uniform Arranged first spring 14; when working, since the power box 2 is in the first cavity and is slidably connected with the fixed shell 13, before the positioning pin 3 is inserted into the positioning hole to realize positioning, the power box 2 will appear in the fixed shell. The phenomenon that the inside of 13 moves forward, backward, left, and right will affect the position positioning of the second connecting rod 23 and the fast and effective clamping of the hot forging blank 25. The evenly arranged first springs 14, through the elastic force of the first springs 14, can make the fixed shell 13 basically located in the middle of the first cavity under the condition of no external force, so the initial position accuracy of the positioning pin 3 can be guaranteed At the same time, it can also prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com