A method and device for high-speed soft transmission and variable pitch handover of bar material

A handover device and variable pitch technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as end empty and external damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The characteristics of the transmission and variable pitch device can be clearly seen from the description. In order to further introduce the present invention, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

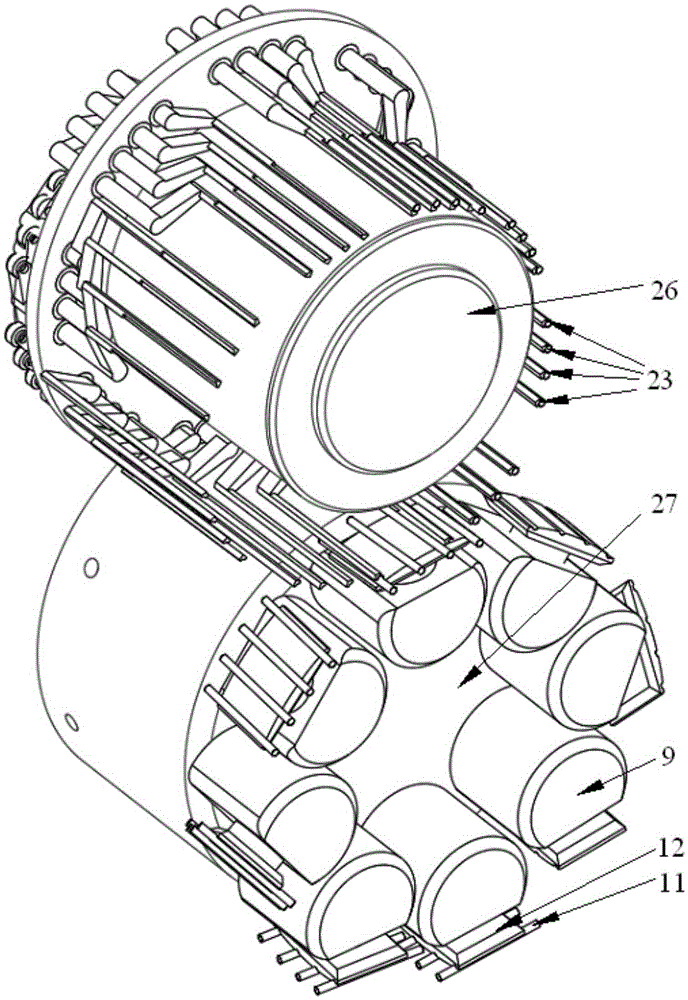

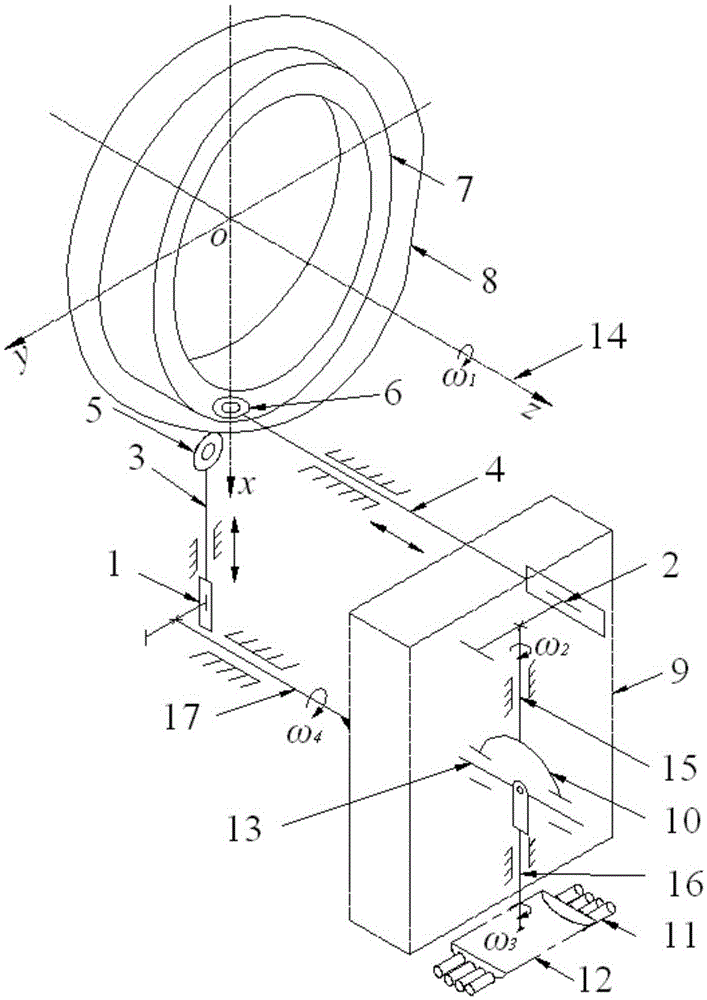

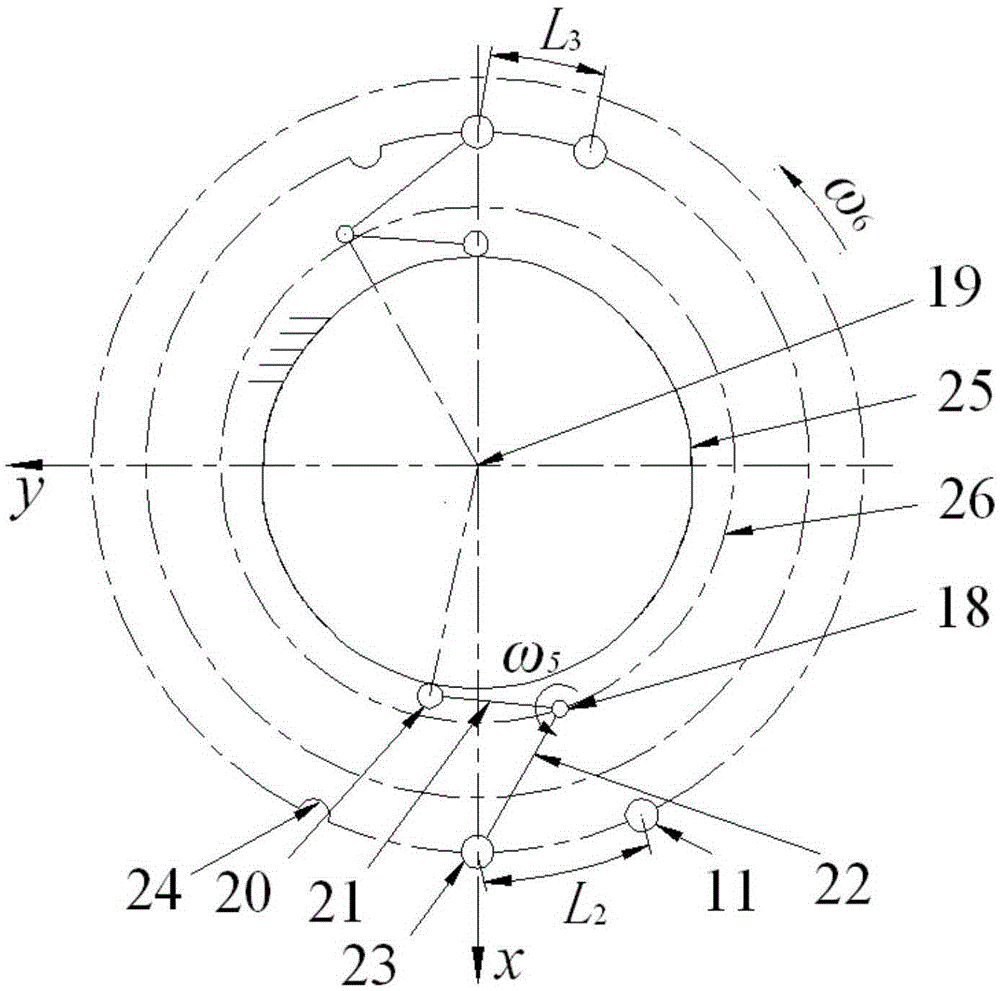

[0049] A bar material high-speed soft transmission and variable pitch transfer device, such as figure 1 , 4 As shown, it includes an axial transmission mechanism and a radial receiving mechanism, and the axial transmission mechanism can transfer a group (each group is preferably 1 or more, such as 4) bars 11 to the radial variable pitch receiving mechanism Above, the axial transmission mechanism includes several (preferably multiple, such as 8) transmission arms 9 mounted on the second wheel body 27, wherein the second wheel body 27 can rotate at a constant speed around the first rotating shaft 14, and the transmission arm 27 A suction groove block 12 is installed, and the suction groove bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com