Alignment clamp for complex shell installation state and alignment method

An installation state and fixture technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of complex shape anisotropy, inability to mark the shape of parts, and inability to achieve alignment, so as to improve the correctness of alignment, The effect of reducing labor costs and eliminating human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050]The correction method provided by the present invention is specifically:

[0051] A. Fixture design, different housings, positioning pins and pressing points are all different.

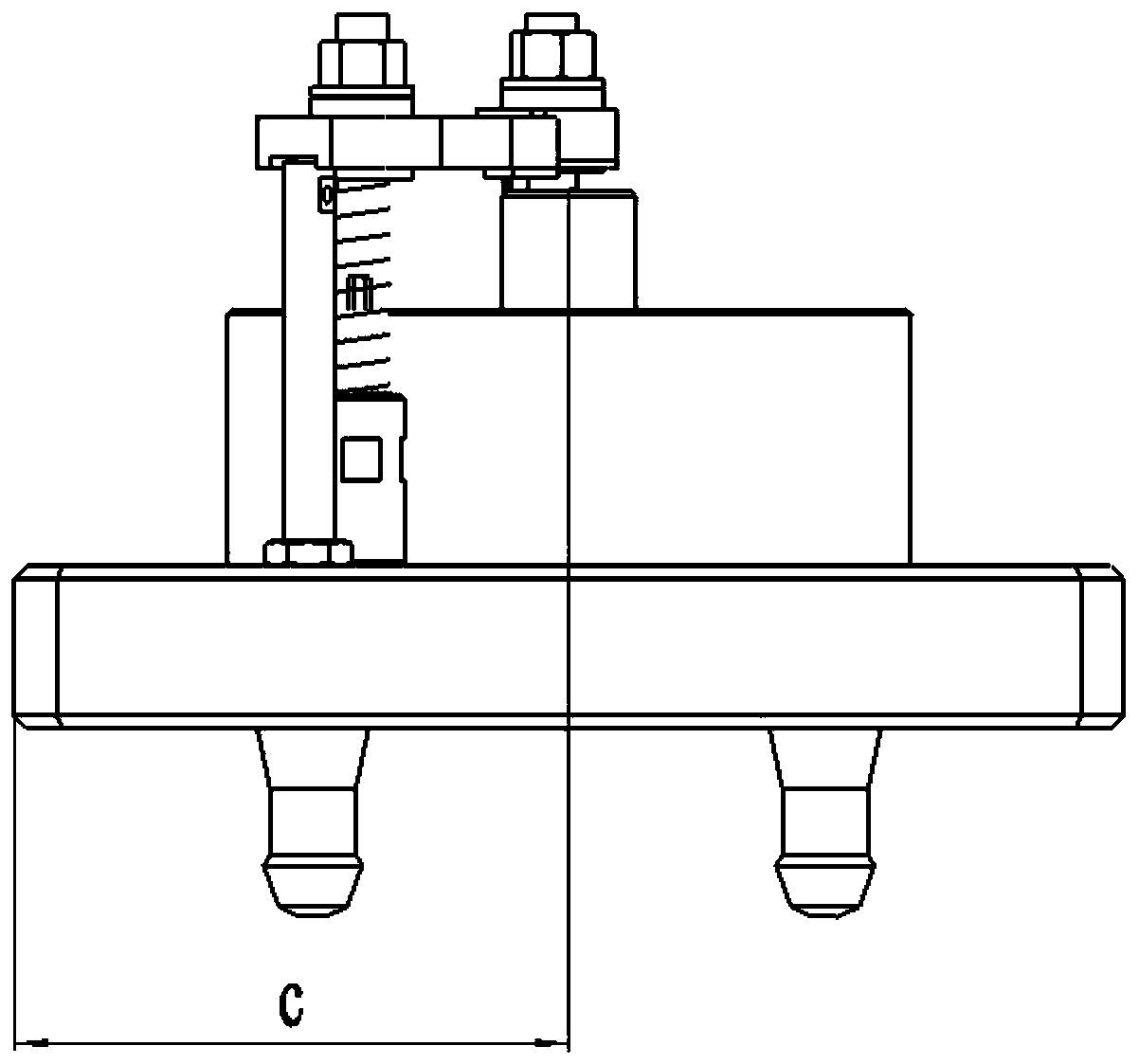

[0052] a. The fixture is designed for complex shells. The shell is clamped and positioned according to a positioning surface (1) and two positioning pins (2). The position size (67, 88) between the two positioning pins is based on the distance between the positioning holes of the parts set up;

[0053] b. Select one of the two positioning pins as the main positioning pin (3), and design an alignment hole (4) on the side of the fixture body. The distance between the alignment hole and the main positioning pin (130, 10, 120) is the absolute size. Change;

[0054] c. There is a clamping rivet (5) at the bottom of the fixture, and the position and size of the rivet are matched with the hole position of the workbench base;

[0055] B. Clamping parts

[0056] A fixed base is installed on the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com