A Zero Focus Compensation Method for Intelligent Laser Cutting Head

A technology of laser cutting head and compensation method, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of affecting the focusing accuracy, increasing the difficulty of use by on-site debugging personnel, etc., to ensure accuracy and reduce hands-on use. Difficulty, the effect of reducing the difficulty of getting started

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

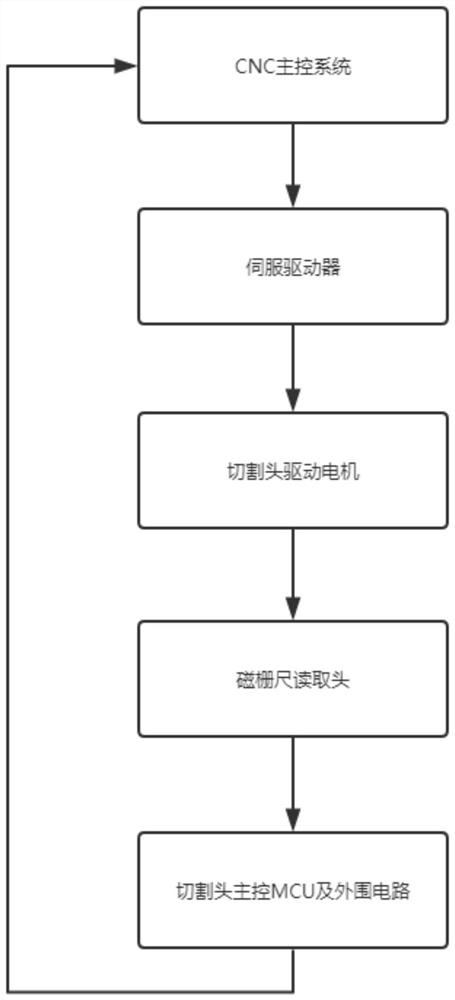

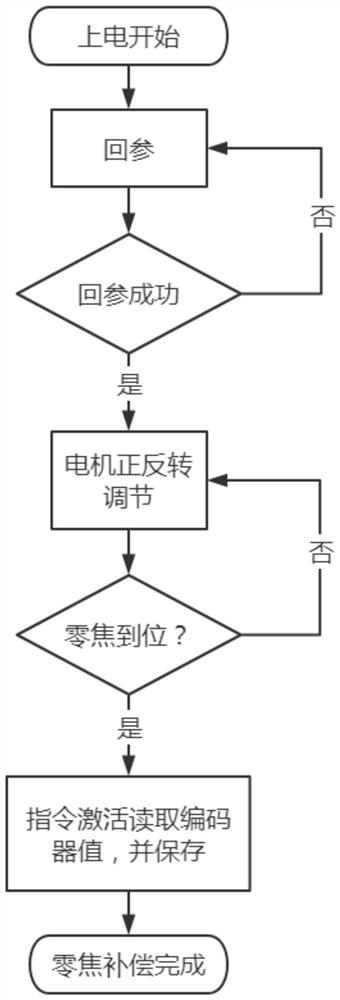

[0044] see Figure 1-4 , a zero-focus compensation method for an intelligent laser cutting head, comprising the following steps:

[0045] S1. The laser cutting head is driven by the cutting head moving device to move up and down, and a magnetic scale is installed on the moving section of the cutting head moving device;

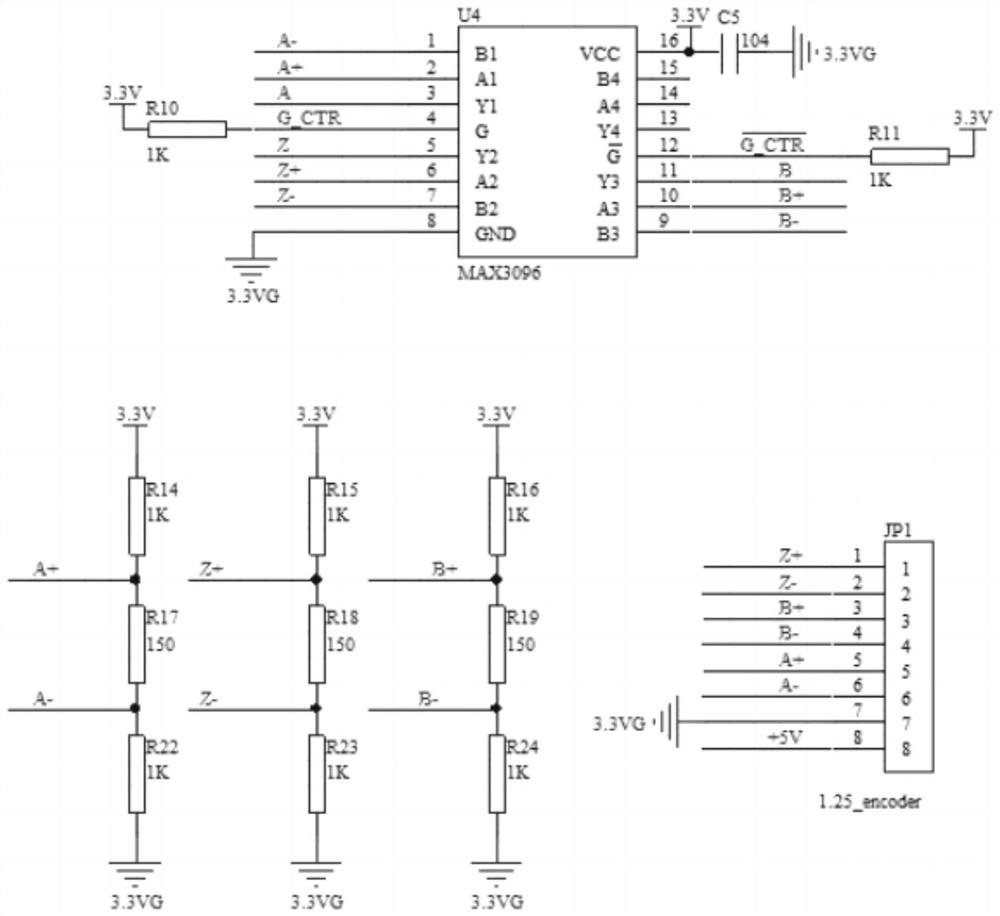

[0046] S2. Read the magnetic grid signal of the magnetic scale through the main control unit MCU, and determine the zero position reference;

[0047] S3. Control the working of the cutting head moving device to drive the laser cutting head to move up and down, thereby driving the focusing lens barrel to move up and down, and stop the movement when the reference returns to the zero point position reference, and record the stay height position of the focusing lens barrel as Y1;

[0048] S4. Control the cutting head moving device to drive the laser cutting head to move up and down, mark the steel plate under the laser cutting head through the laser cutting head,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com