Explosive cladding method of tantalum/zirconium/titanium/steel explosive clad plate

A technology of explosive composite plate and steel plate, which is applied in the direction of welding/welding/cutting items, non-electric welding equipment, manufacturing tools, etc., can solve the unfavorable development of national industry, unfavorable promotion and application of tantalum/zirconium/titanium/steel explosive composite plate equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

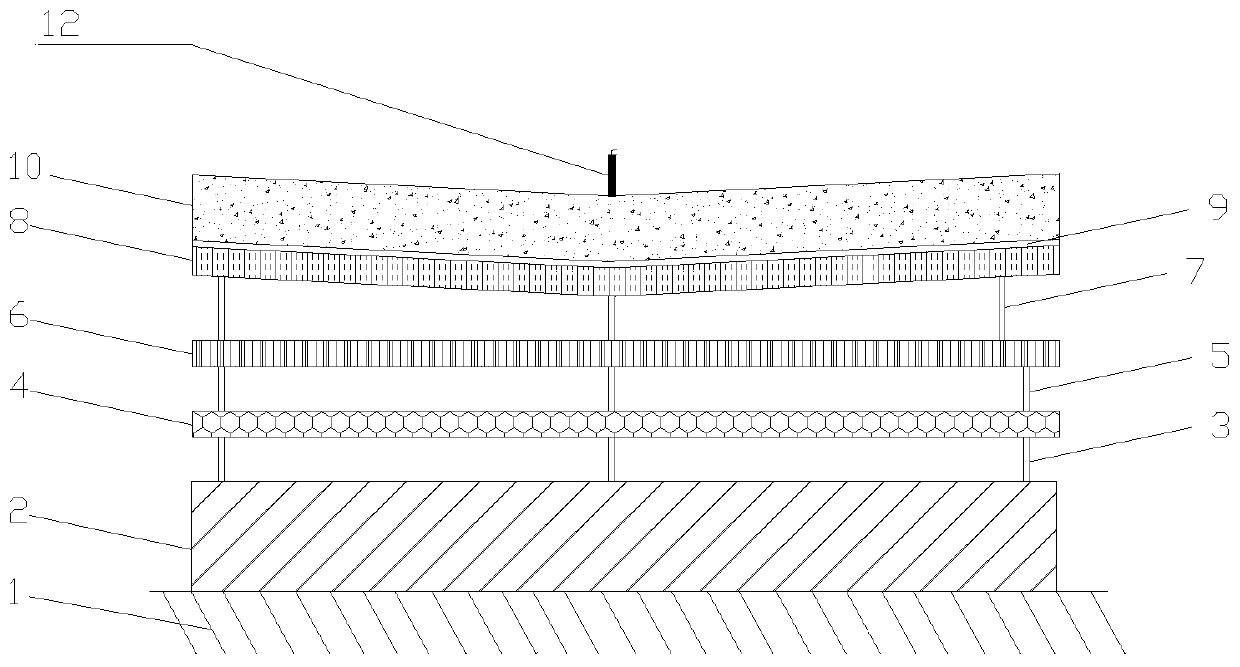

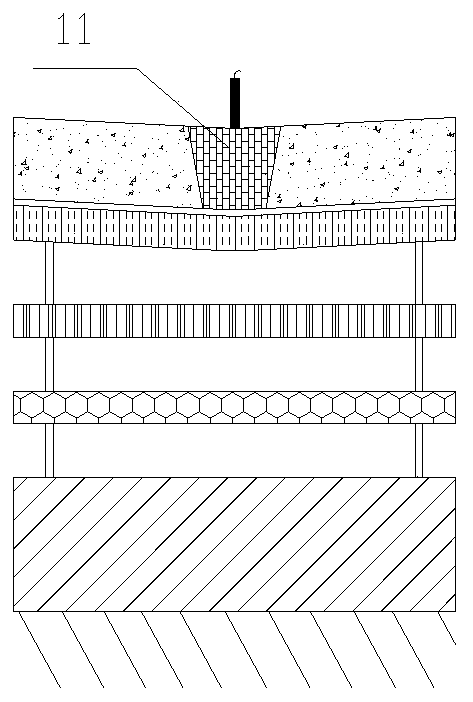

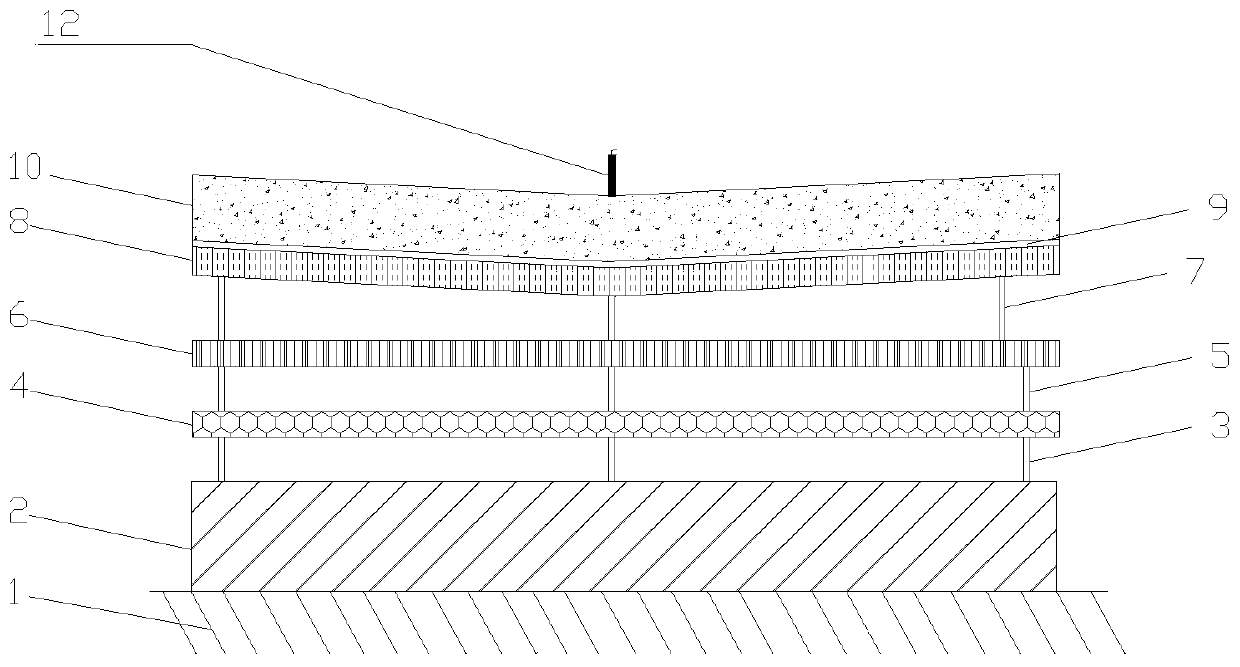

[0029] An explosive composite method for a tantalum / zirconium / titanium / steel explosive composite plate, the specific steps are as follows:

[0030] S1: Cut the steel plate 2, titanium plate, zirconium plate 6, and tantalum plate 8 according to the required size, and polish the upper surface of the steel plate 2, the lower surface of the tantalum plate 8, the upper and lower surfaces of the titanium plate, and the zirconium plate 6 the upper and lower surfaces of

[0031] S2: Select an area with hard and flat soil, lay yellow sand, and use it as foundation 1 after leveling;

[0032] Among them, the thickness of yellow sand laying is 50mm.

[0033] S3: The steel plate 2 is placed on the foundation 1, and the excess yellow sand around the steel plate 2 is removed;

[0034] S4: cleaning the upper surface of the steel plate 2 to ensure the cleanliness, and evenly placing the first supporting member on the upper surface;

[0035] Wherein, the height of the first support is 10 mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com