Straw treatment device for rural areas

A technology for processing device and straw, applied in crop processing machines, agriculture, agricultural machinery and implements, etc., can solve the problems of unfavorable fermentation, poor energy saving, restricting processing efficiency, etc., to simplify the power structure design, improve the crushing effect, and reduce the cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

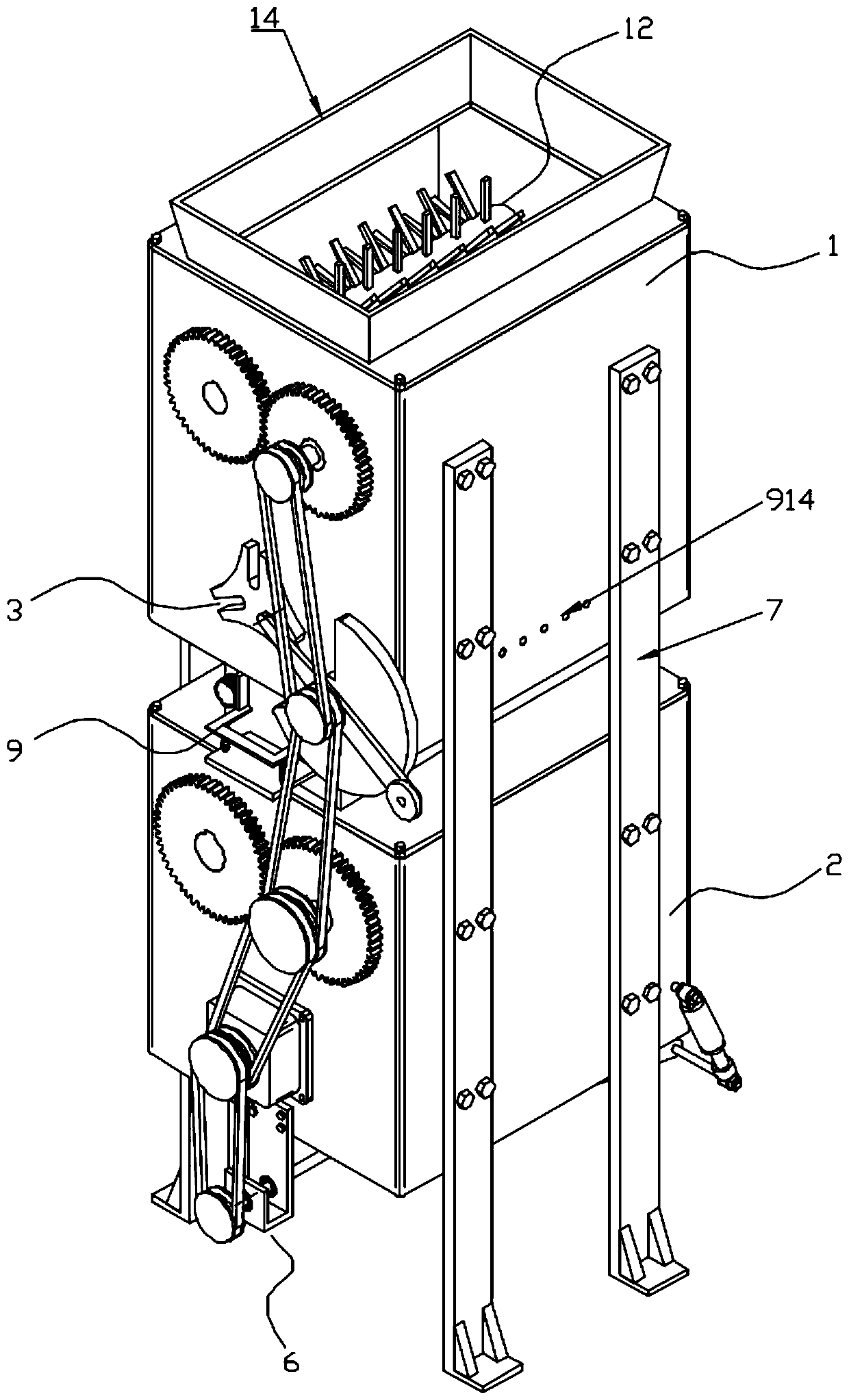

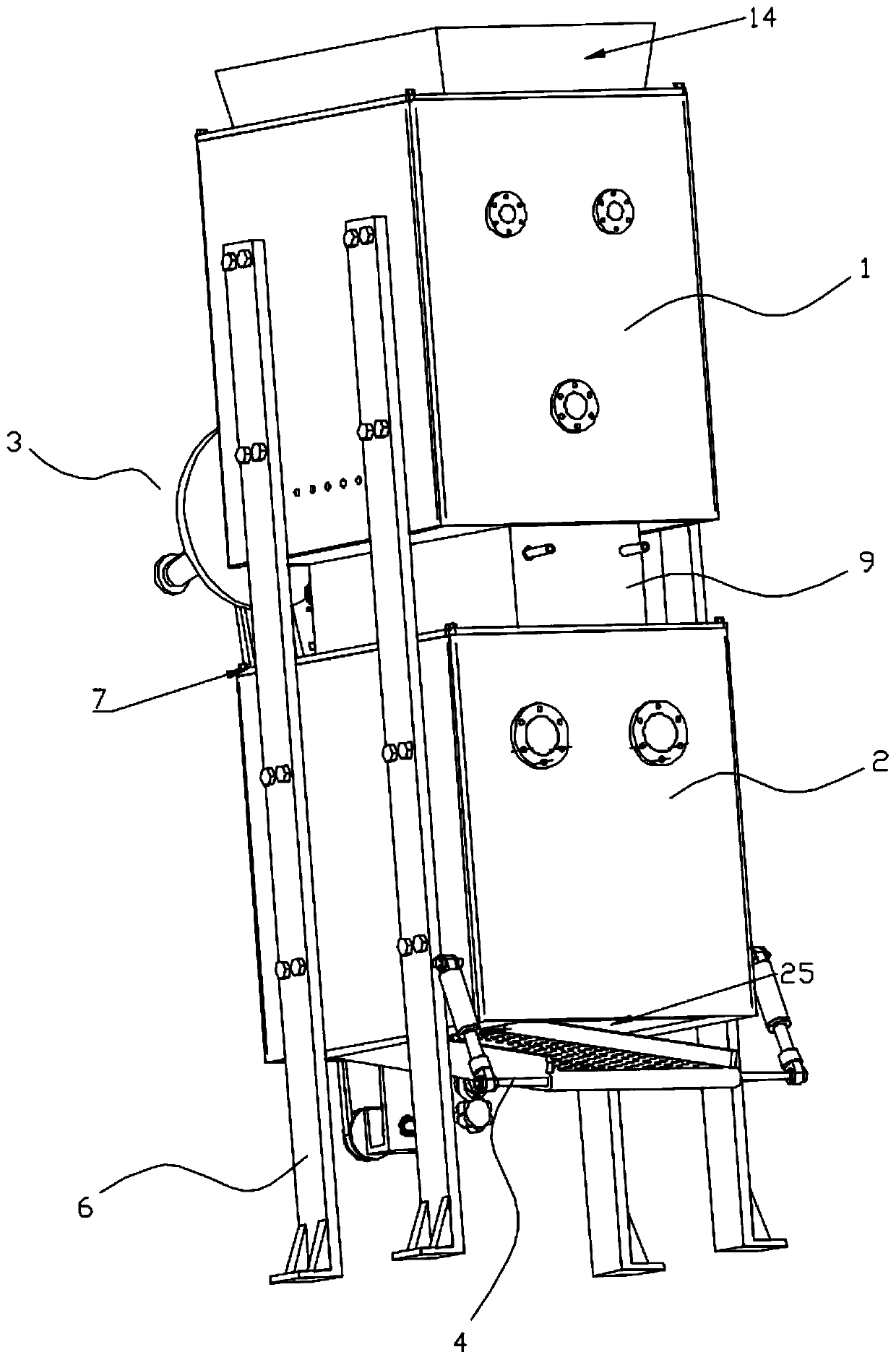

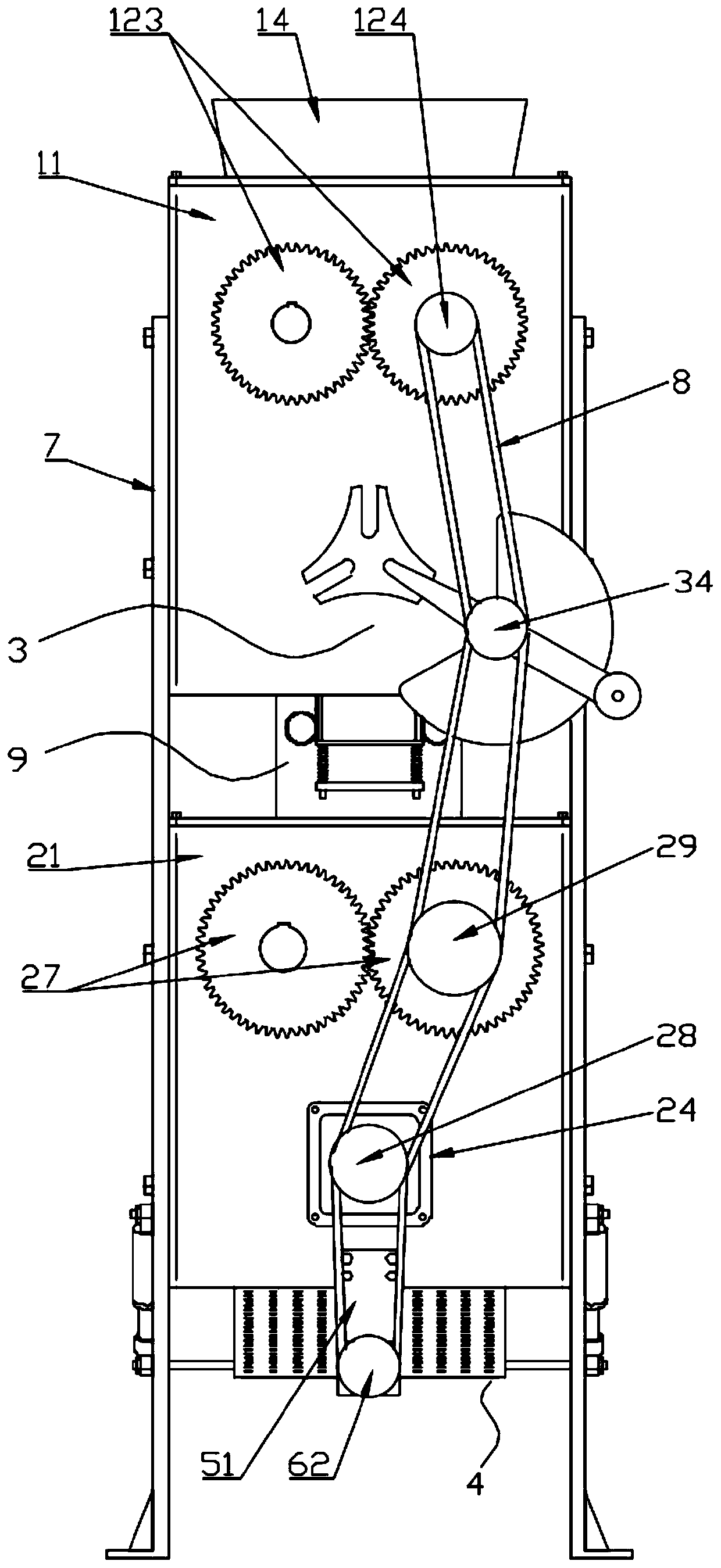

[0039] like Figure 1 to Figure 18As shown, a rural straw processing device includes a stirring and feeding device 1, a crushing device 2, a screening mechanism 4 and a support frame 7, and the support frame 7 is installed on both sides of the stirring and feeding device 1 and the crushing device 2 and is used to play The supporting function and the stirring and feeding device 1 is located directly above the crushing device 2;

[0040] Described stirring feeding device 1 comprises casing one 11, stirring mechanism 12 and feeding mechanism 13, and the top and the bottom of casing one 11 are respectively provided with feed opening one 14 and discharge opening one 15, described stirring mechanism 12 and feeding Mechanisms 13 are rotatably connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com