Anti-collision transformer with high safety

A transformer and safety technology, applied in the direction of transformer/inductor shell, etc., can solve the problems of low safety, easy leakage, poor anti-collision effect of transformers, etc., to improve safety, avoid secondary accidents, and solve anti-collision effects poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

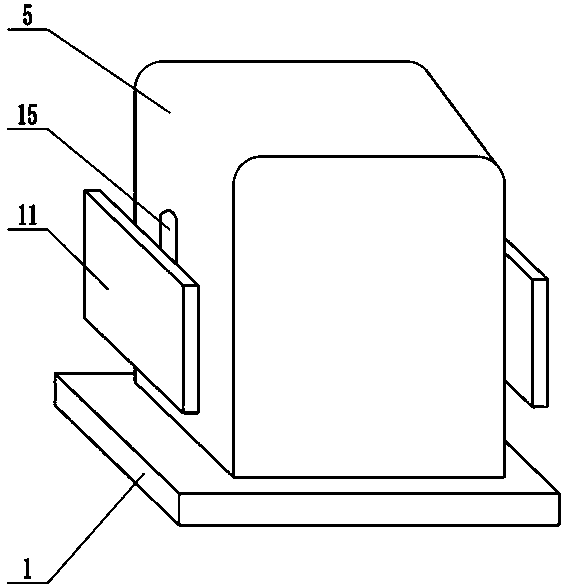

[0020] see Figure 1-3 , in the embodiment of the present invention, a high-safety anti-collision transformer includes a base 1, a casing 5, a transformer body 8 and a buffer plate 11, the base 1 is buried in the ground, and a fixing assembly is installed on the bottom of the base 1 , the fixed component includes a fixed pile 2, a fixed plate 3 and a fixed rod 4, the lower surface of the base 1 is fixedly connected with the fixed pile 2, the lower end of the fixed pile 2 is fixedly connected with the fixed plate 3, and the lower surface of the fixed plate 3 is distributed with fixed Rod 4, the stability of the device can be improved by using the fixing assembly, so that the device can be more firmly connected to the ground. The upper surface of the base 1 is detachably mounted with a shell 5, and the inside of the shell 5 is provided with a fixed plate 6. The fixed plate 6 There are two in total, which are arranged symmetrically on the left and right. A transformer body 8 is i...

Embodiment 2

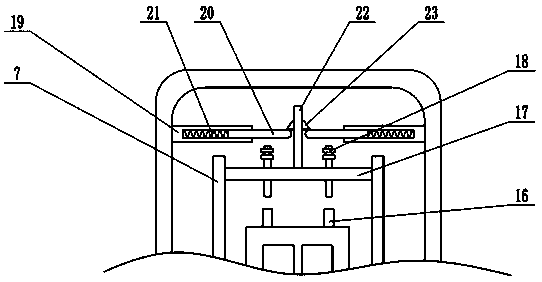

[0022] On the basis of Embodiment 1, a positioning mechanism is installed inside the casing 5, and the positioning mechanism includes a fixed cylinder 19, a movable rod 20 and a positioning spring 21, and the side wall of the casing 5 is fixedly connected with a fixed cylinder 19, and there are two fixed cylinders 19. , arranged symmetrically left and right, a movable rod 20 is installed inside the fixed cylinder 19, and the movable rod 20 is slidingly connected with the fixed cylinder 19, and the movable rod 20 can slide left and right in the fixed cylinder 19, and a positioning spring 21 is installed inside the fixed cylinder 19, when When being hit, lifting plate 17 moves upwards, thereby drives fixed plate 22 to move upwards, utilizes positioning tooth 23 to push movable rod 20, movable rod 20 is moved to both sides, after positioning tooth 23 moves to the top of movable rod 20, utilizes Positioning teeth 23 block the lifting plate to prevent the lifting plate 17 from falli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com