Crop airing device

A drying device and a technology for crops, which are applied to drying solid materials, drying gas layout, dryers for stationary materials, etc. Uneven drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

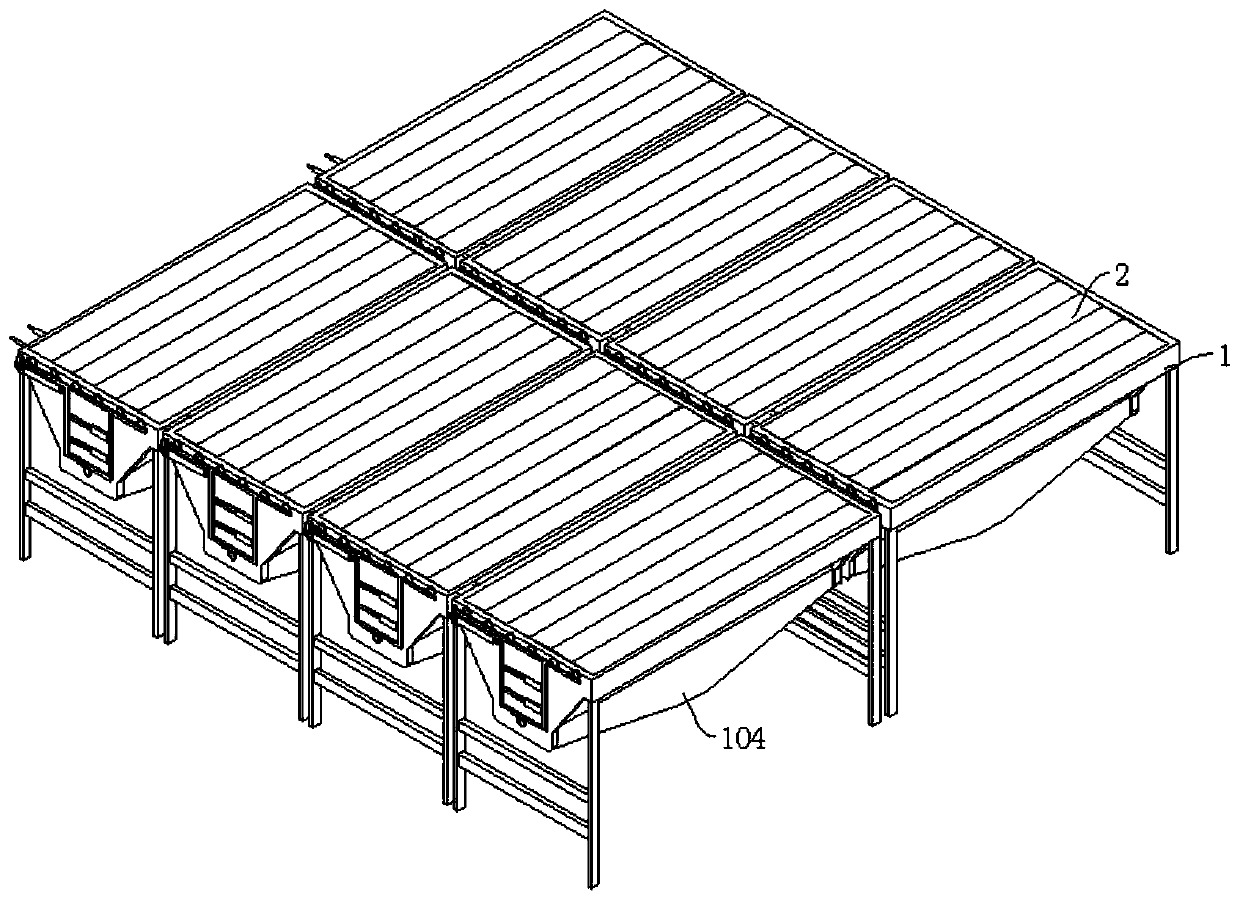

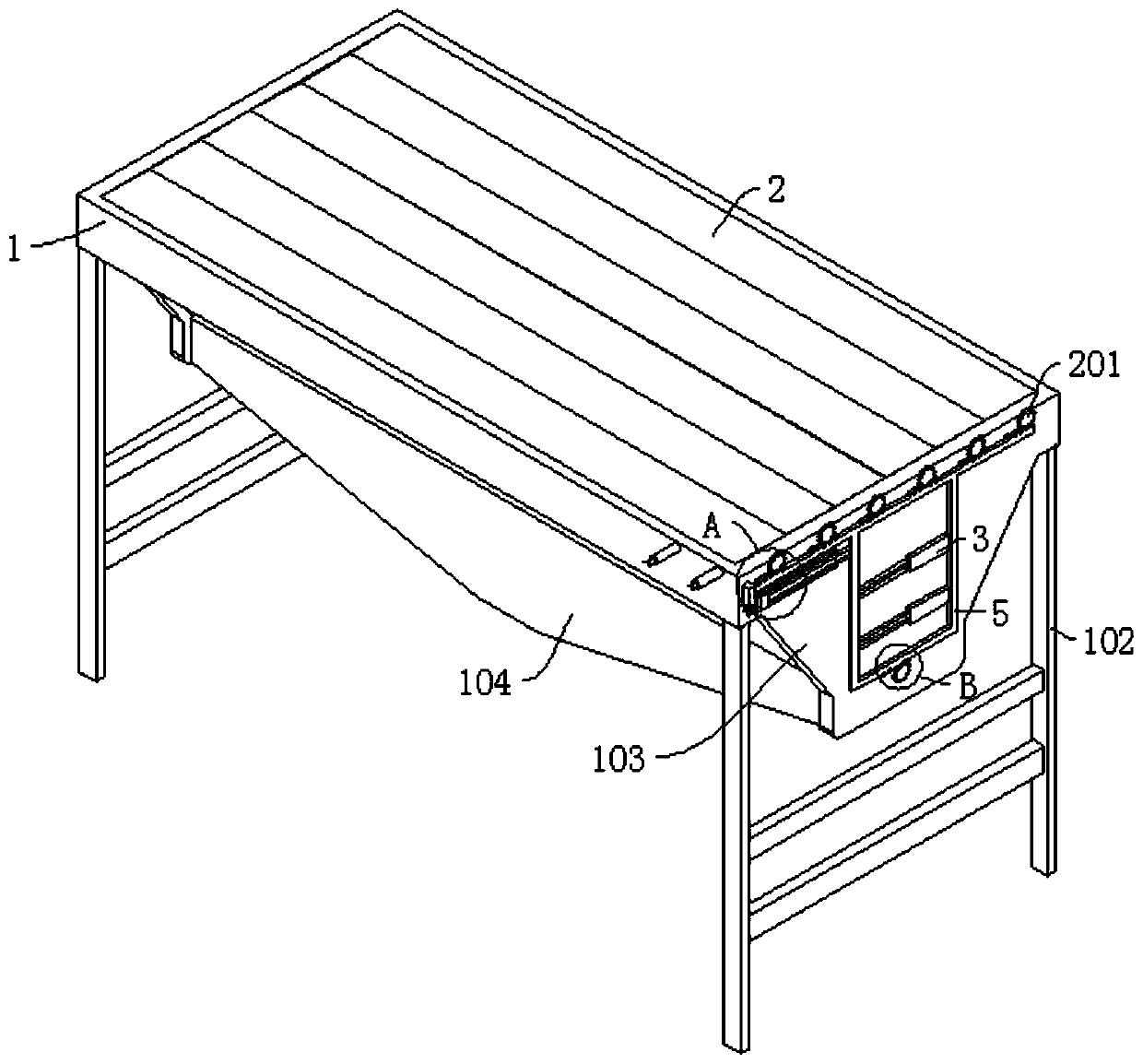

[0030] refer to Figure 1-9 , a crop drying device, including a bracket 1, and also includes a connecting frame 5 slidably connected to the side wall of the bracket 1, the side wall of the bracket 1 is connected with a driving part for pushing the connecting frame 5 to slide on the bracket 1;

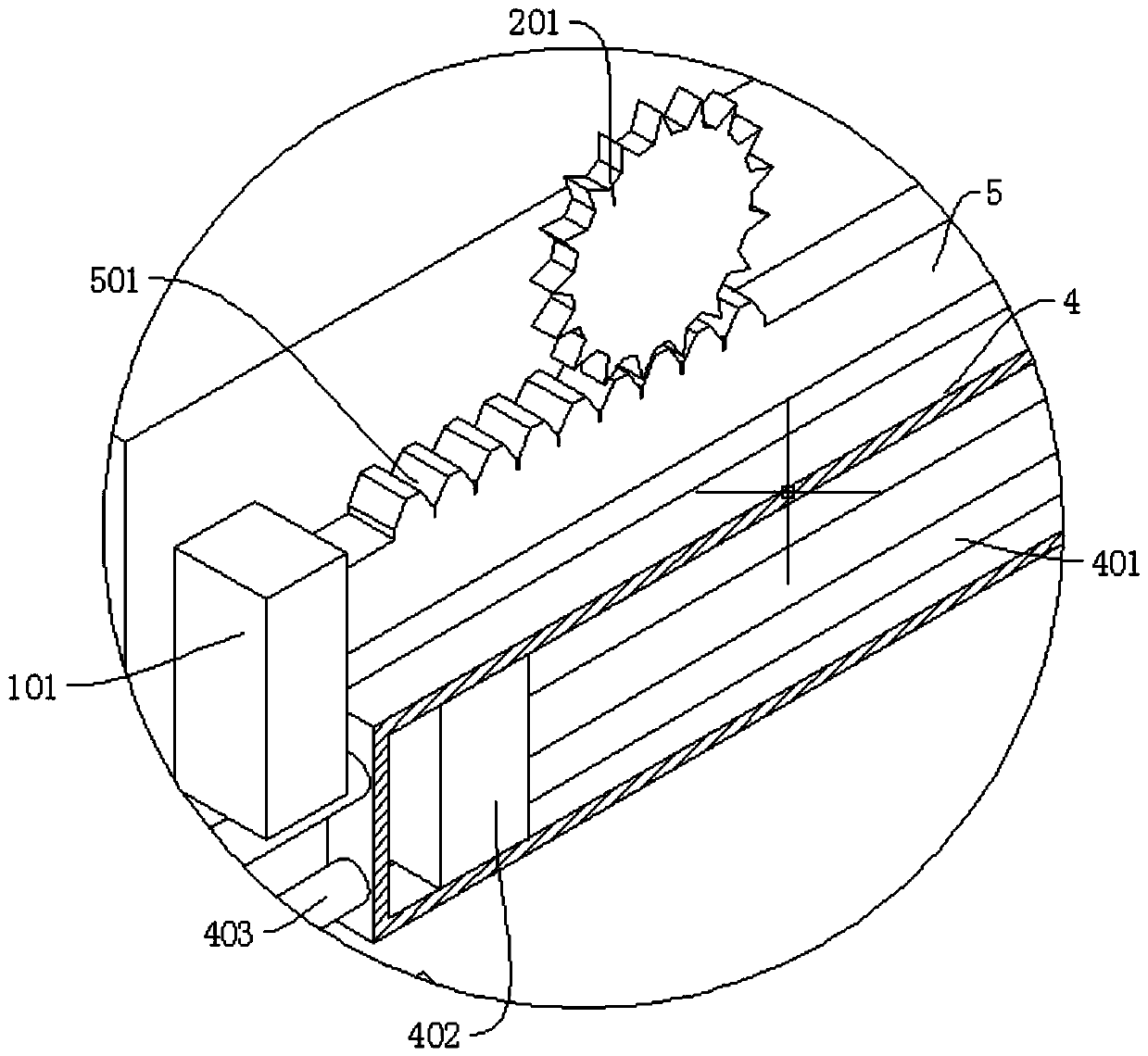

[0031] The drying device also includes a plurality of drying boards 2 rotatably connected to the bracket 1. The side wall of the bracket 1 is connected with a plurality of first gears 201, and the plurality of first gears 201 are fixedly connected with the drying board 2 to drive the drying board 2 to rotate. The upper end of the connecting frame 5 is connected with a first gear tooth 501, and the first gear tooth 501 meshes with the first gear 201;

[0032] The bottom of the bracket 1 is fixedly connected with a first collecting box 103, the bottom of the first collecting box 103 is fixedly connected with a second collecting box 104, the bottom of the first collecting box 103 is connec...

Embodiment 2

[0035] refer to Figure 2-6 , which is basically the same as that of Embodiment 1, furthermore, the bracket 1 is located on the side wall of the connecting frame 5 and is connected with a first sealed box 4, and the first sealed box 4 is slidably connected with a first air-tight block 402, the first The air seal block 402 is fixedly connected with a push rod 401, the other end of the push rod 401 is fixedly connected with the connecting frame 5, the side wall of the support 1 is connected with a second sealing box 404, and the second sealing box 404 is slidingly connected with a second gas The sealing block 405, the second air sealing block 405 is fixedly connected with the insertion rod 406, and the drying plate 2 is dug with a socket 202, and the end of the insertion rod 406 away from the second air sealing block 405 passes through the side wall of the bracket 1 and is inserted into the socket 202 , the first sealed box body 4 and the second sealed box body 404 are sealed an...

Embodiment 3

[0038] refer to Figure 7 , is basically the same as in Embodiment 1, furthermore, the bottom of the first collecting box 103 is connected with an arc-shaped baffle 1031, and the side wall of the sealing plate 602 is arc-shaped, so that the sealing plate 602 and the first collecting The box 103 fits closely to further prevent material leakage.

[0039] The cross section of the first collecting box 103 is triangular and the bottom is provided with an opening communicating with the second collecting box 104 .

[0040] The bottom of the second collecting box 104 is provided with a discharge port, which is convenient for the grains to be concentrated, so that the discharge port is discharged.

[0041] Cylinder 3 is used as the drive unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com