Combed cotton/graphene polyamide interweaved fabric and production process thereof

A production process, graphene nylon technology, which is applied in the field of combed cotton/graphene nylon interwoven fabric and its production process, can solve the problems of unable to meet the functional requirements of consumers, weaken the market competitiveness of products, increase production costs, etc., and achieve The effect of dyeing and coloring is good, it is not easy to dye flowers, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A combed cotton / graphene nylon interwoven fabric, consisting of the following components:

[0048] Combed cotton 60 parts,

[0049] Graphene nylon 40 parts.

[0050] Among them, combed cotton is used as the surface, and graphene nylon is used as the bottom (skin-friendly surface).

[0051] A kind of production of combed cotton / graphene nylon interwoven fabric, comprises the following steps:

[0052] (1) Weaving: Using the cotton-covered silk plain weave method, the combed cotton and graphene nylon are woven into plain fabrics through a loom, wherein the number of needles is 20, and the number of inches is 34; the total number of needles is 2136T.

[0053] (2) Reservation: Use the setting machine to make reservations, the predetermined temperature is 190°C, the number of machines is 20Y / min, the overfeed is 20%, the width is 64 inches, and the weight is 155g / m 2 ;

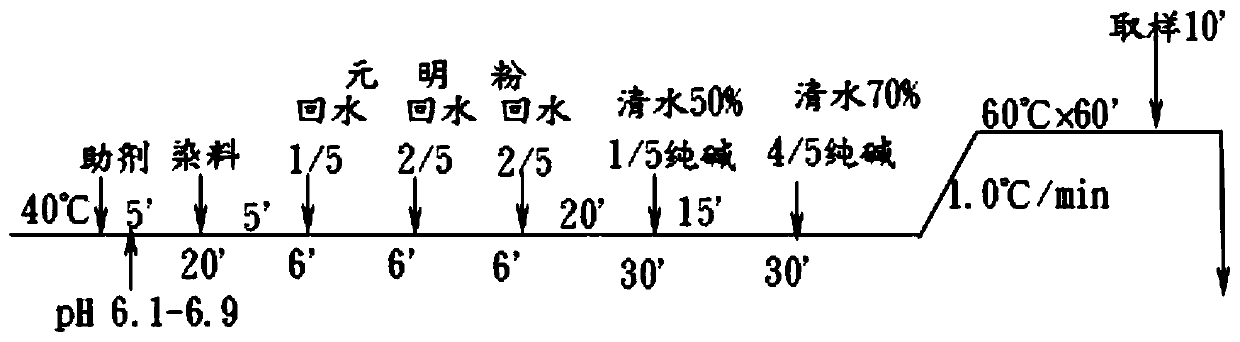

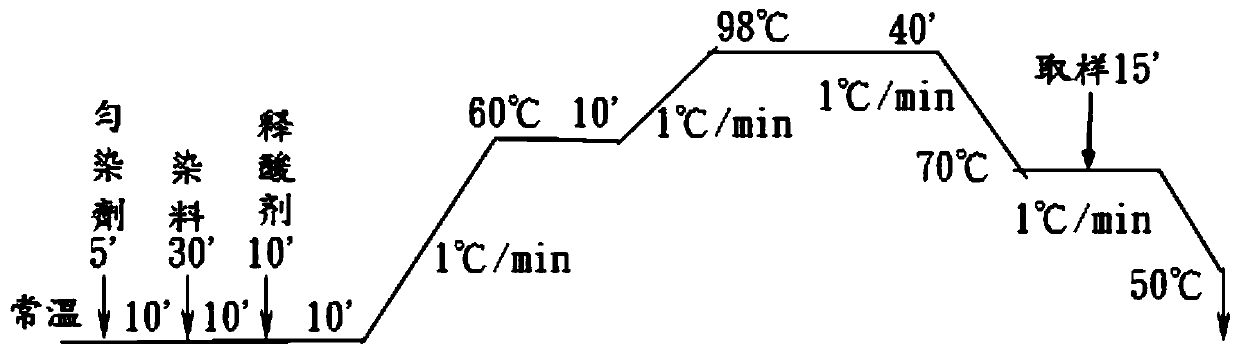

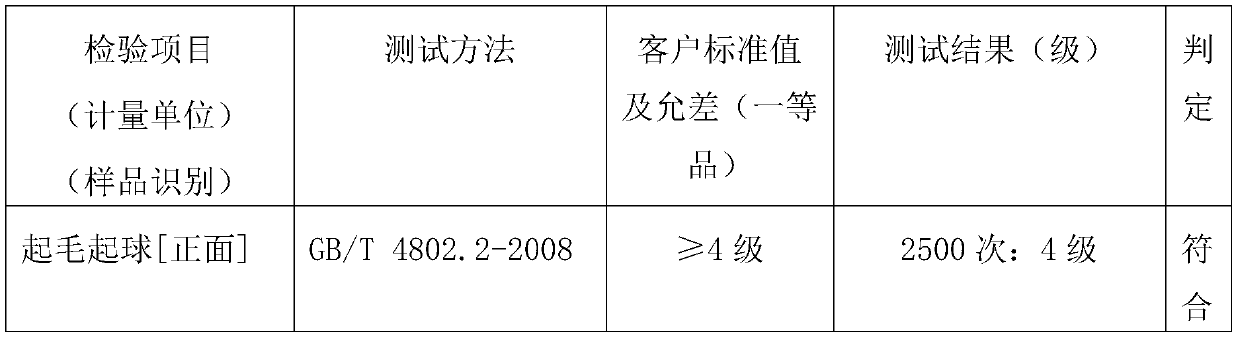

[0054] (3) Pretreatment: use a dyeing machine for pretreatment, the pretreatment bath ratio is 1:7, the ...

Embodiment 2

[0063] A combed cotton / graphene nylon interwoven fabric, consisting of the following components:

[0064] Combed cotton 70 parts,

[0065] 30 parts of graphene nylon.

[0066] Further, combed cotton is used as the surface, and graphene nylon is used as the bottom (skin-friendly surface).

[0067] A kind of production of combed cotton / graphene nylon interwoven fabric, comprises the following steps:

[0068] (1) Weaving: Using the cotton-covered silk plain weave method, the combed cotton and graphene nylon are woven into plain fabrics through a loom, wherein the number of needles is 22, and the number of inches is 34; the total number of needles is 2376T.

[0069] (2) Reservation: Use the setting machine to make reservations, the predetermined temperature is 192°C, the number of machines is 22Y / min, the overfeed is 22%, the width is 64 inches, and the weight is 158g / m 2 ;

[0070] (3) Pre-treatment: use a dyeing machine for pre-treatment, the pre-treatment bath ratio is 1:7....

Embodiment 3

[0079] A combed cotton / graphene nylon interwoven fabric, consisting of the following components:

[0080] Combed cotton 67 parts,

[0081] Graphene nylon 33 parts.

[0082] Further, combed cotton is used as the surface, and graphene nylon is used as the bottom (skin-friendly surface).

[0083] A kind of production of combed cotton / graphene nylon interwoven fabric, comprises the following steps:

[0084] (1) Weaving: Using the cotton-covered silk plain weave method, the combed cotton and graphene nylon are woven into plain fabrics through a loom, wherein the number of needles is 24, and the number of inches is 34; the total number of needles is 2592T.

[0085] (2) Reservation: Use the setting machine to make reservations, the predetermined temperature is 195°C, the number of machines is 24Y / min, the overfeed is 25%, the width is 64 inches, and the weight is 160g / m 2 ;

[0086] (3) Pretreatment: use a dyeing machine for pretreatment, the pretreatment bath ratio is 1:8, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com