Double-cutter cutting mechanism of bale breaker

A double-knife cutting and unpacking machine technology, used in cutting and unsealing, packaging, transportation and packaging, etc., can solve the problems of material residue, mixed bag fragments, woven bags that cannot be cut, etc., and achieve a complete cutting edge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

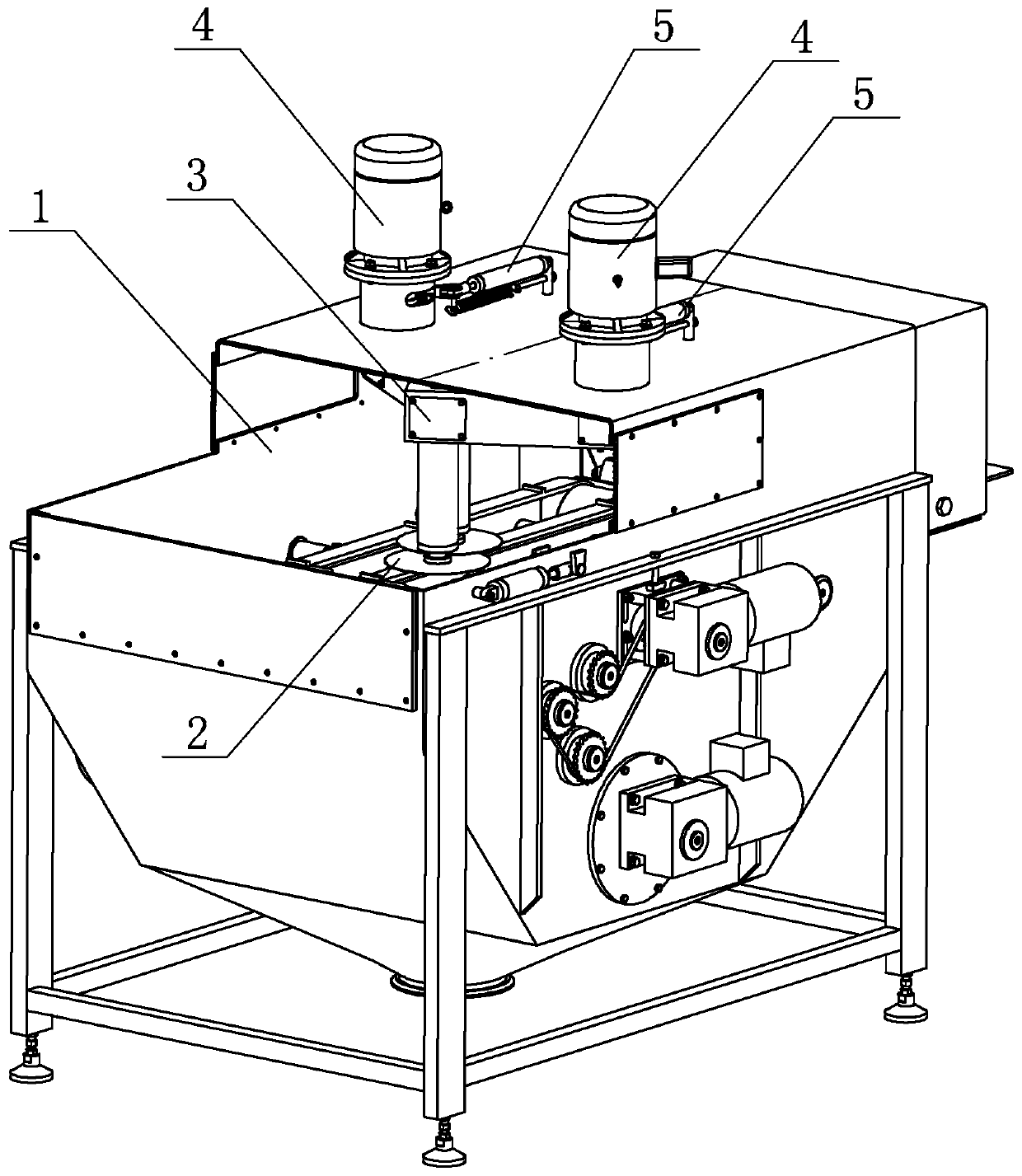

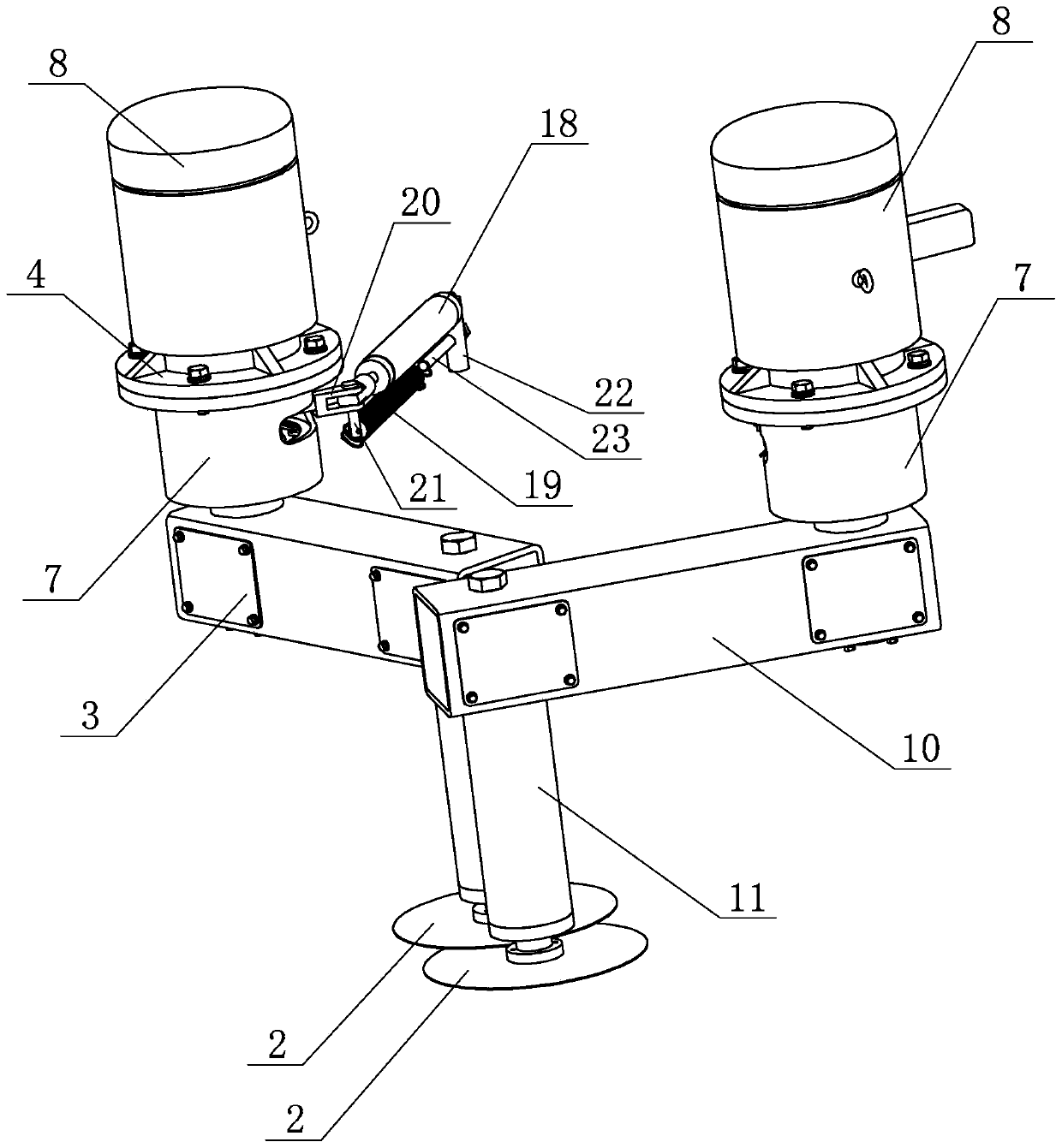

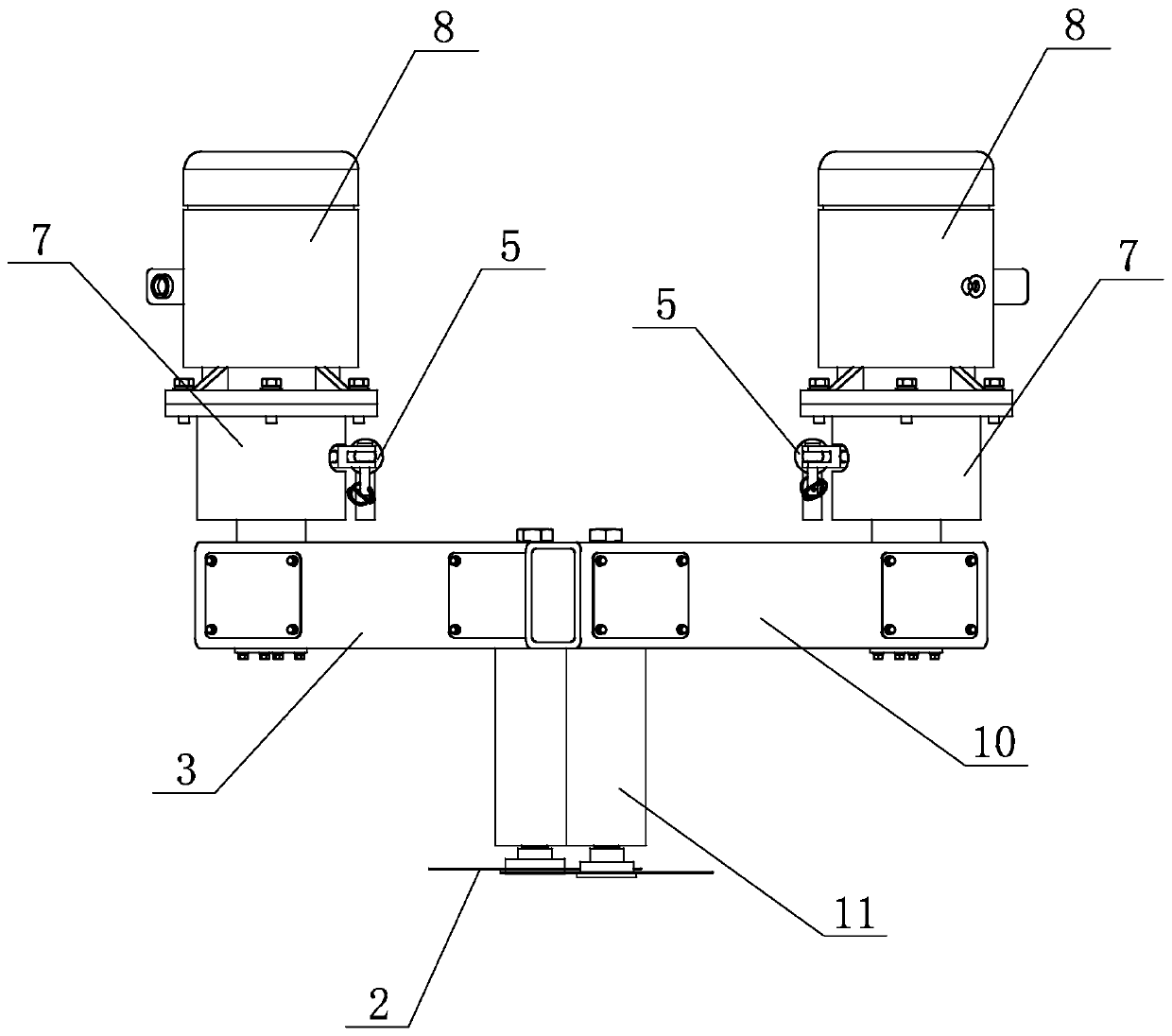

[0024] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, the double-knife cutting mechanism of a kind of unpacking machine of this embodiment is installed on the frame 1, and it comprises two cutting knives 2, two blade transmission mechanisms 4 that drive cutting knives, complete swing arm mechanism 3 reset There are two reset mechanisms 5 and two sets of swing arm mechanisms 3. The swing arm mechanisms 3 are installed above the inside of the frame 1. Each set of swing arm mechanisms 3 has a "┌┘" shape structure. The lower parts of the two sets of swing arm mechanisms 3 Relatively set, a cutting knife 2 is horizontally installed on the lower end of each group of swing arm mechanisms 3, the upper part of each group of swing arm mechanisms 3 is connected with a blade transmission mechanism 4 respectively, and the extended end of each reset mechanism 5 is connected with a blade transmission mechanism 4 are connected, and the fixed end of e...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination Figure 1 to Figure 7 The present embodiment will be described, and the cutting blade 2 of the present embodiment is a disc blade. Such setting, using the setting of cutting knife 2, is helpful for cutting small dry powder packaging bags of different materials, helping the disassembled packaging bags to be complete and the cutting edges are neat, improving the emptying rate of materials and reducing mixed packaging bags in materials possibility of fragmentation. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 1 to Figure 7 Describe this embodiment, the blade transmission mechanism 4 of this embodiment comprises motor 8, motor base 7, hollow shaft 6 and first bearing 9, motor base 7 is installed on the frame 1, motor 8 is installed on the motor base 7, hollow The shaft 6 is installed inside the motor base 7 through the first bearing 9 . With such arrangement, the transmission mode is simple and reliable. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com