Zero calibration unmanned steering engine and control method

A technology of unmanned driving and steering gear, which is applied in the direction of steering mechanism, electric steering mechanism, power steering mechanism, etc., can solve the problems of inconvenient popularization, high motor power, high price, etc., and achieve good induction effect, low cost and easy modification simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

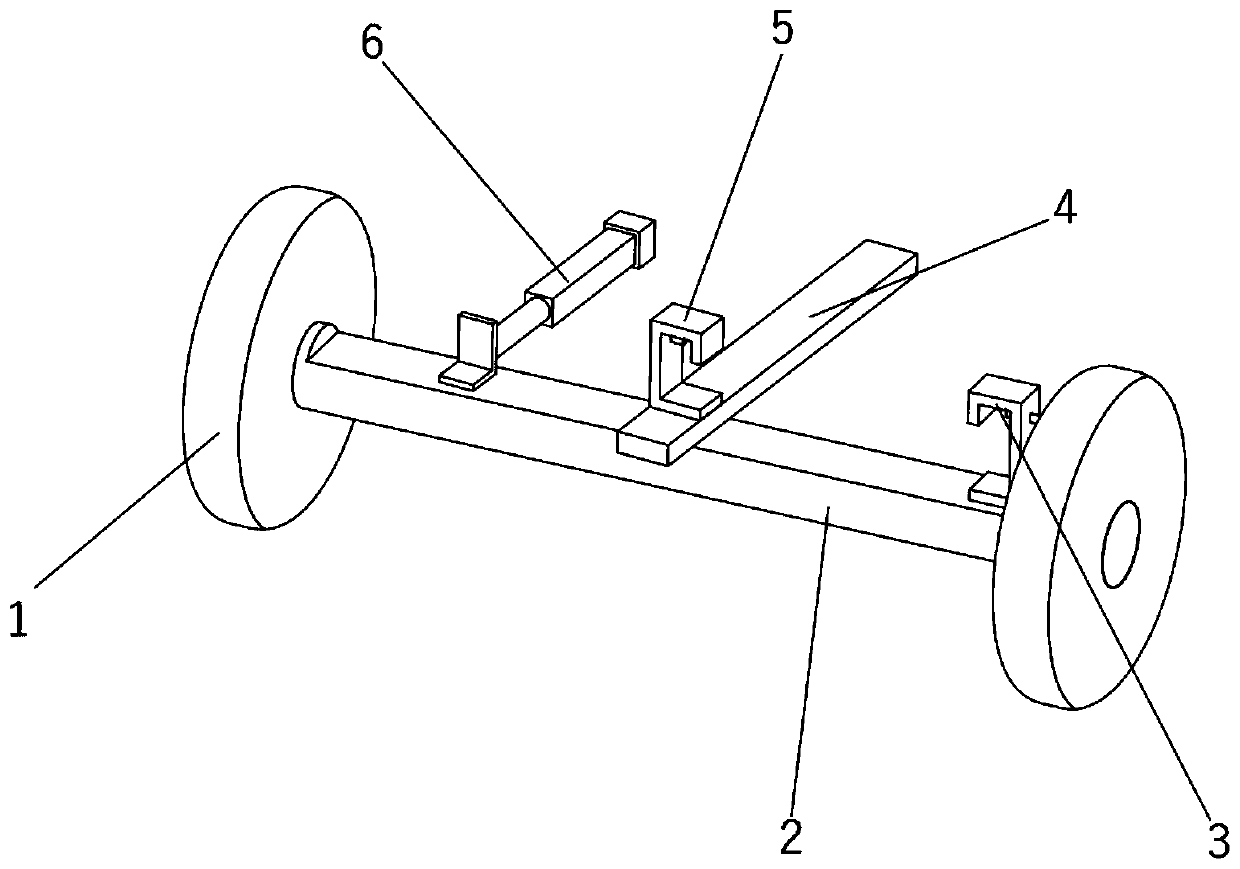

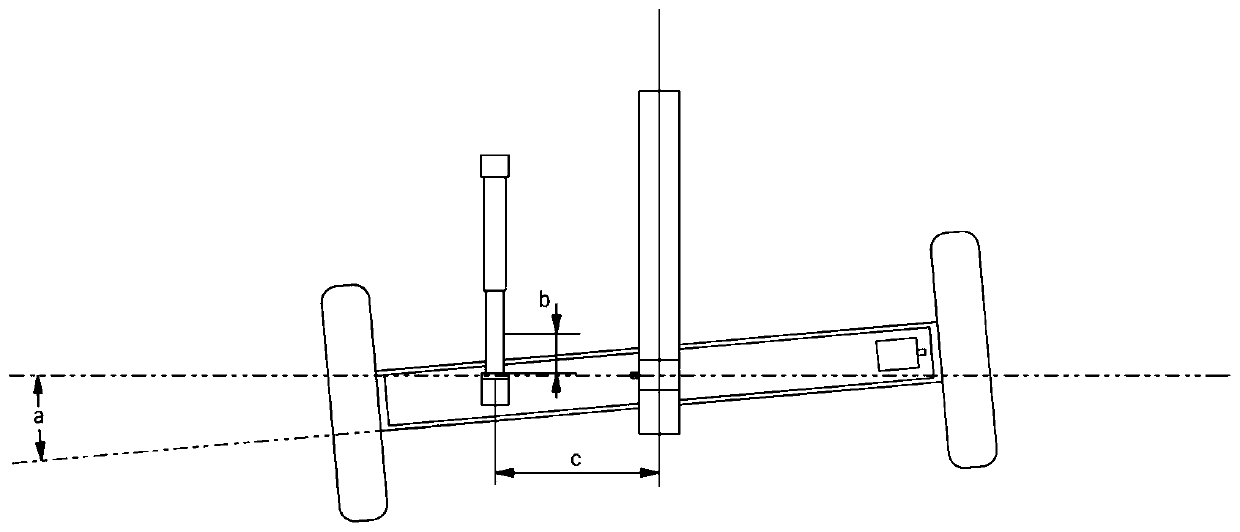

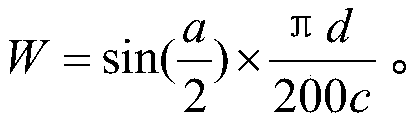

[0036] refer to Figure 1-2 As shown, a zero calibration unmanned steering machine includes a wheel 1, a wheel shaft 2, an infrared laser transmitter 3, a frame 4, an infrared laser receiver 5, a push rod motor 6 and a single-chip microcomputer system, and the wheel 1 is fixed in rotation At both ends of the wheel shaft 2, the frame 4 is fixed on the center of the wheel shaft 2 through the rotation of the shaft, the infrared laser receiving end 5 is fixed on the frame 4, the infrared laser emitting end 3 is fixed on the wheel rotating shaft 2 and the infrared laser emitting end 3 Close to one end of the wheel shaft 2, the end of the push rod motor 6 is fixed, the first end is fixed on the wheel shaft 2 and the head end of the push rod motor 6 is close to the end of the wheel shaft 2 that is not the infrared laser emitting end 3, the push rod motor 6, the infrared laser Both the transmitting end 3 and the infrared laser receiving end 5 are electrically connected to the single-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com