Front floor positioning device for automobile spot welding and using method thereof

A positioning device and front floor technology, which is applied to auxiliary devices, vehicle parts, welding equipment, etc., can solve the problems of incomplete processing, inconvenient front floor positioning, and inability to deal with welding smoke, so as to improve spot welding efficiency and ensure spot welding Accuracy, Guaranteed Healthy Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

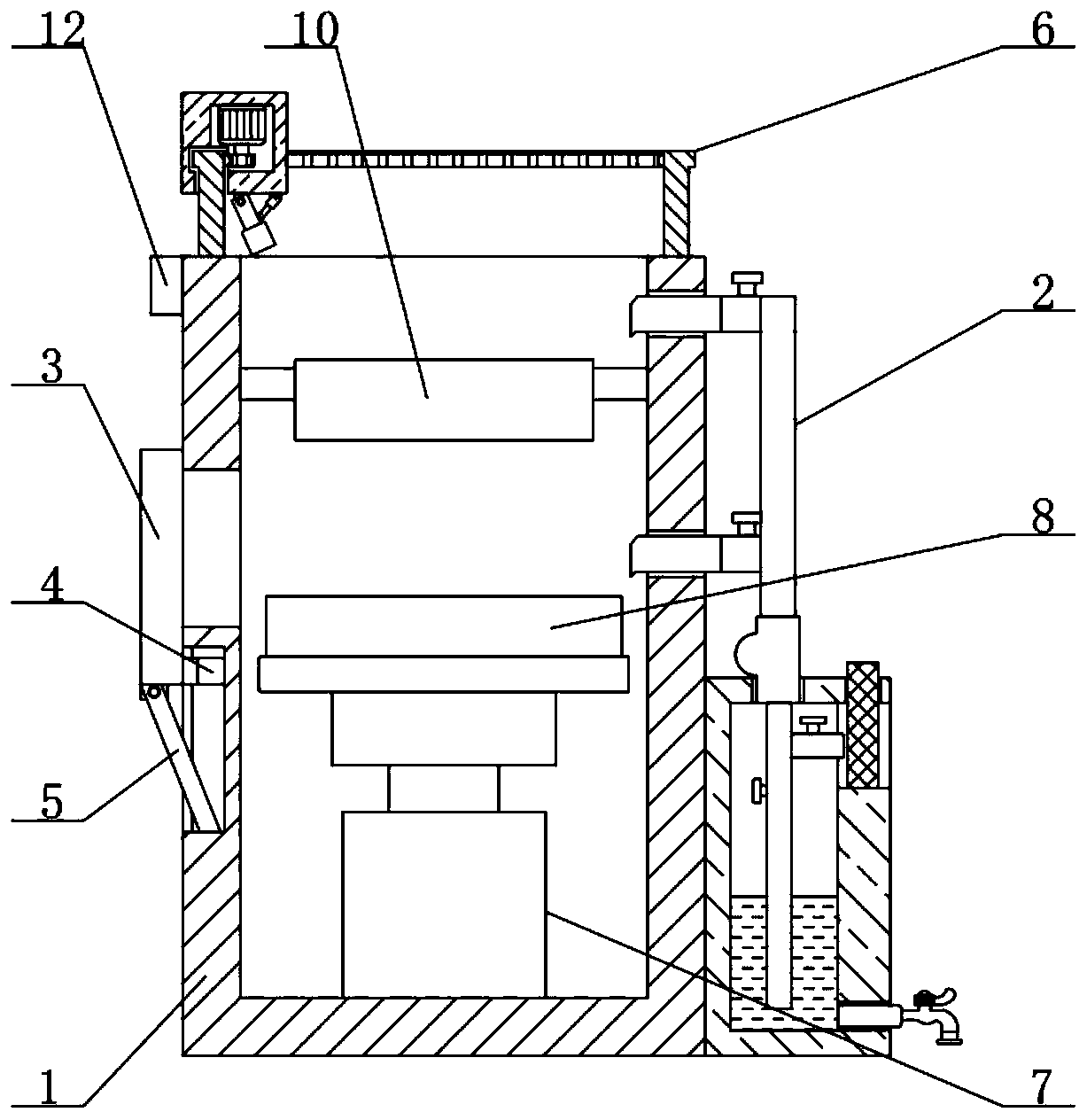

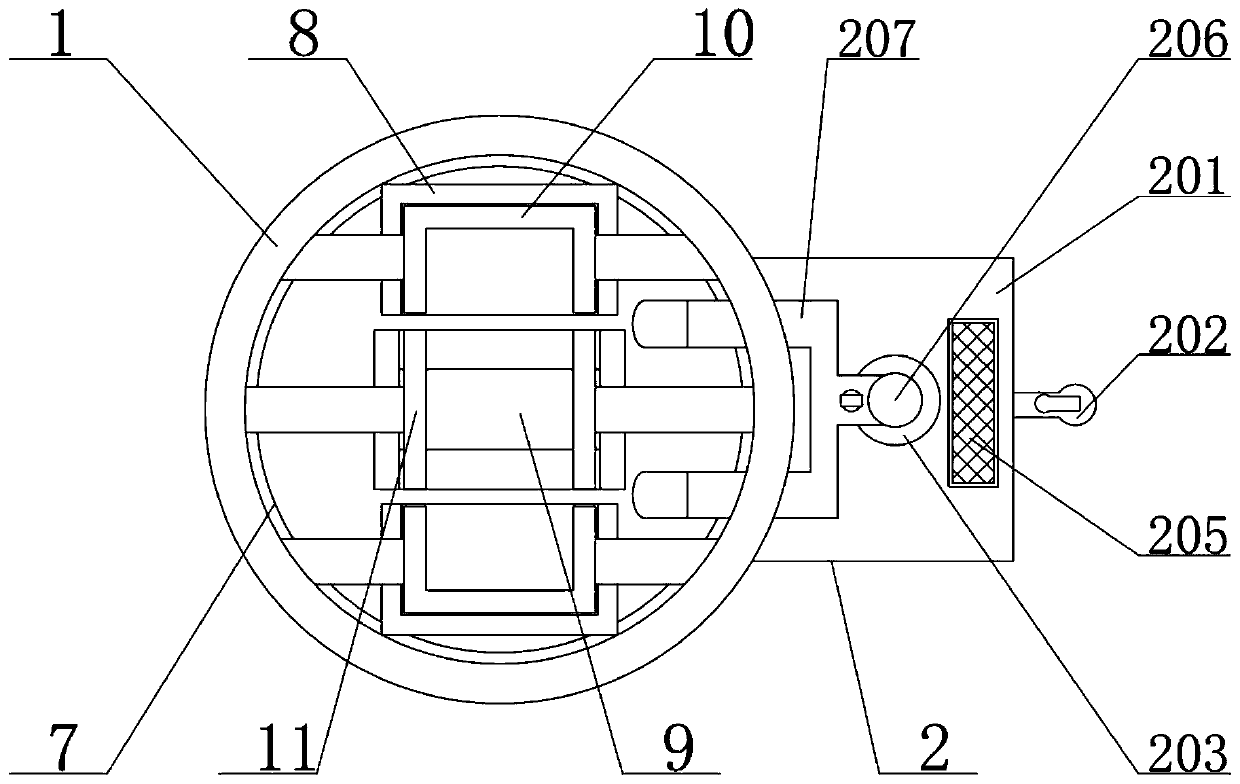

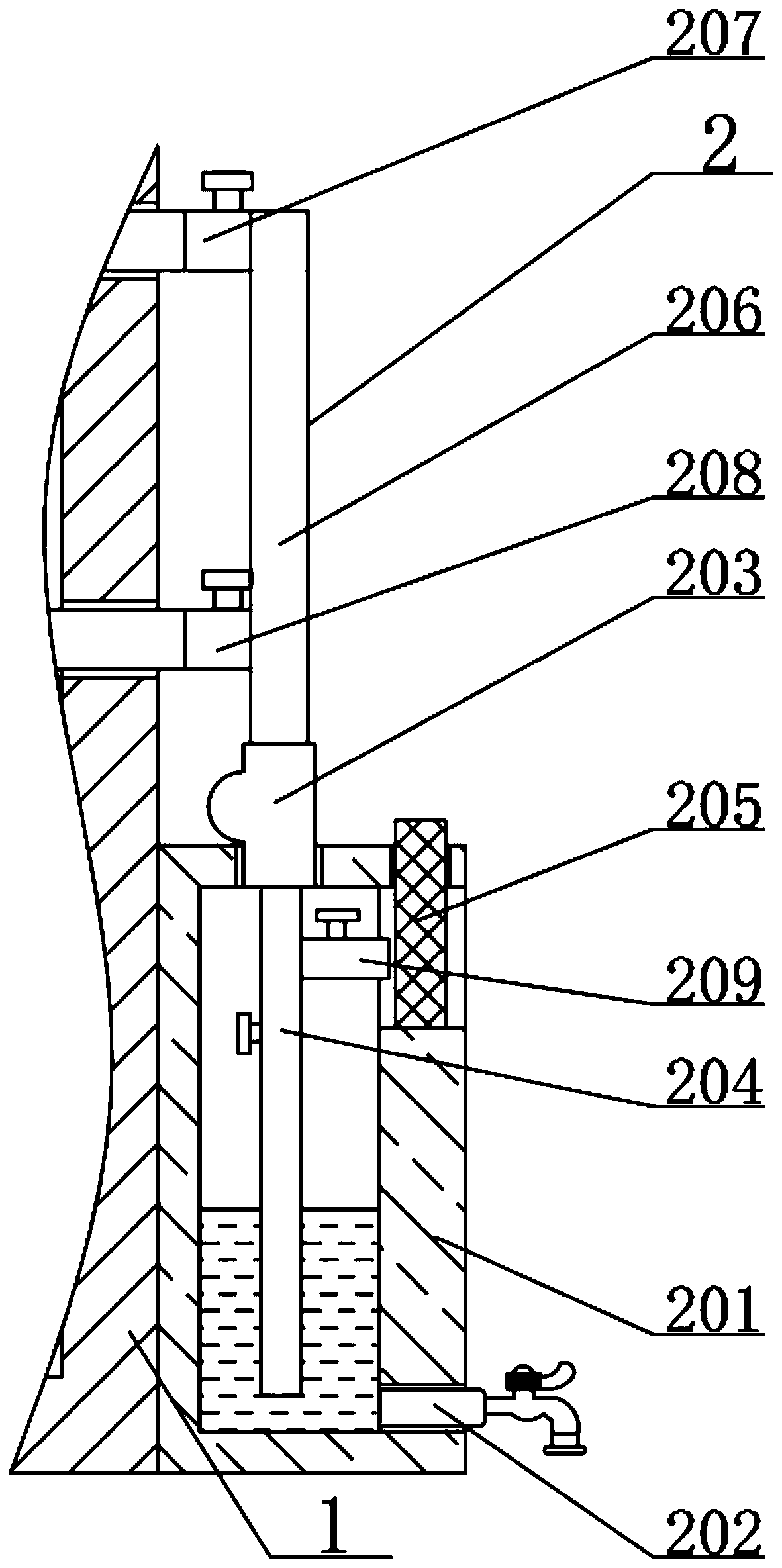

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 with Figure 7 , the present invention provides a technical solution:

[0033]A front floor positioning device for automobile spot welding and its use method, comprising a positioning frame 1, a processing device 2, a monitoring device 6 and a positioning device 7, the right end of the positioning frame 1 is provided with a processing device 2, and the processing device 2 includes a processing box 201, Water faucet 202, air pump 203, air outlet pipe 204, filter screen 205, air extraction pipe 206, first transfer pipe 207, second transfer pipe 208 and delivery pipe 209, the bottom end of the right end face of positioning frame 1 is fixedly connected with treatment box 201, treatment box The bottom of the right end face of 201 is connected with a faucet 202, the top of the treatment box 201 is connected with an air pump 203, the bottom of the air pump 203 is connected with an air outlet pipe 204...

Embodiment 2

[0041] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 with Figure 7 , the present invention provides a technical solution:

[0042] A front floor positioning device for automobile spot welding and its use method, comprising a positioning frame 1, a processing device 2, a monitoring device 6 and a positioning device 7, the right end of the positioning frame 1 is provided with a processing device 2, and the processing device 2 includes a processing box 201, Water faucet 202, air pump 203, air outlet pipe 204, filter screen 205, air extraction pipe 206, first transfer pipe 207, second transfer pipe 208 and delivery pipe 209, the bottom end of the right end face of positioning frame 1 is fixedly connected with treatment box 201, treatment box The bottom of the right end face of 201 is connected with a faucet 202, the top of the treatment box 201 is connected with an air pump 203, the bottom of the air pump 203 is connected with an air outlet pipe 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com