Waste disposal recycle method

A waste and industrial waste technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as complex composition of solid waste, unstable incineration temperature, and slow feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

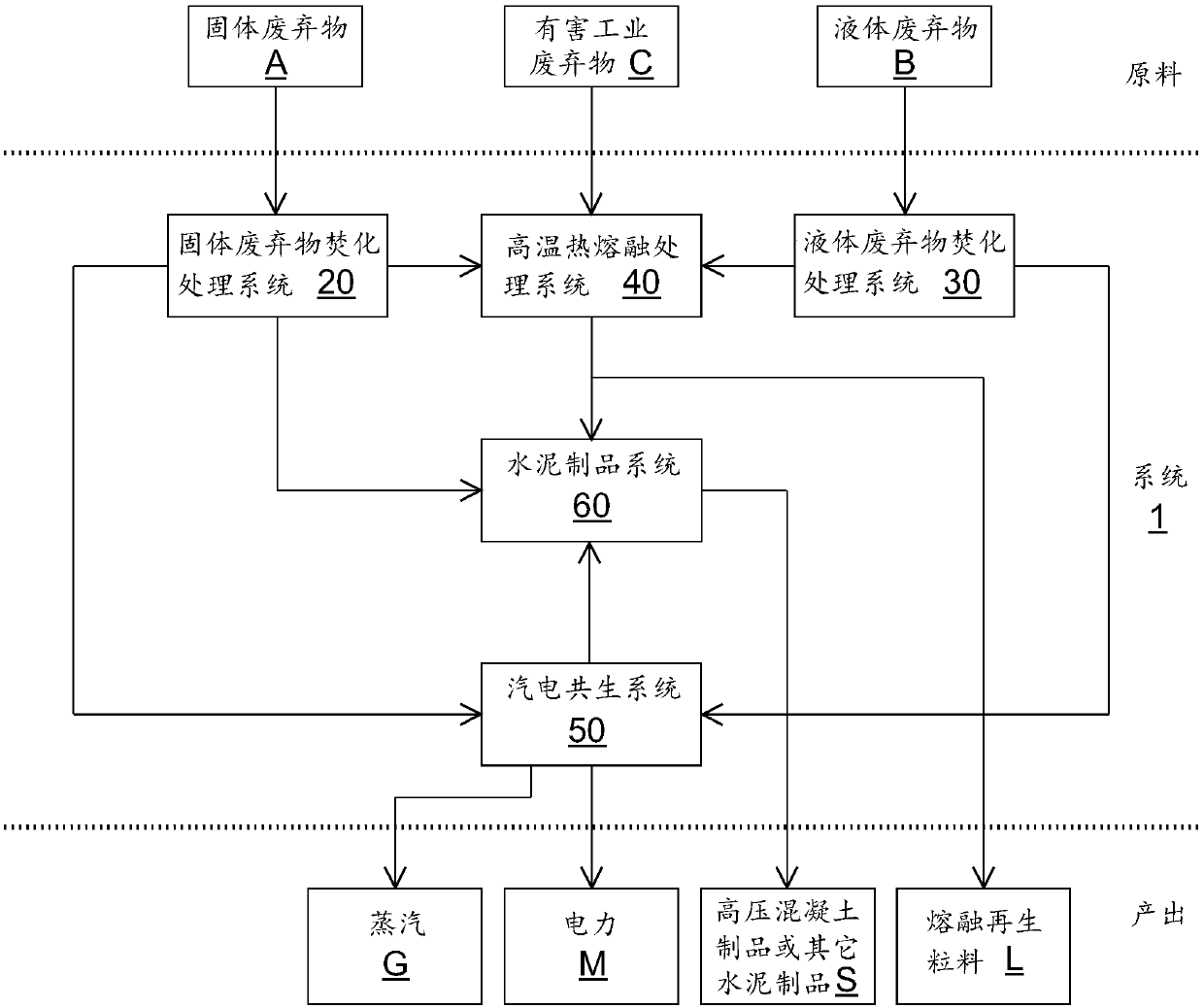

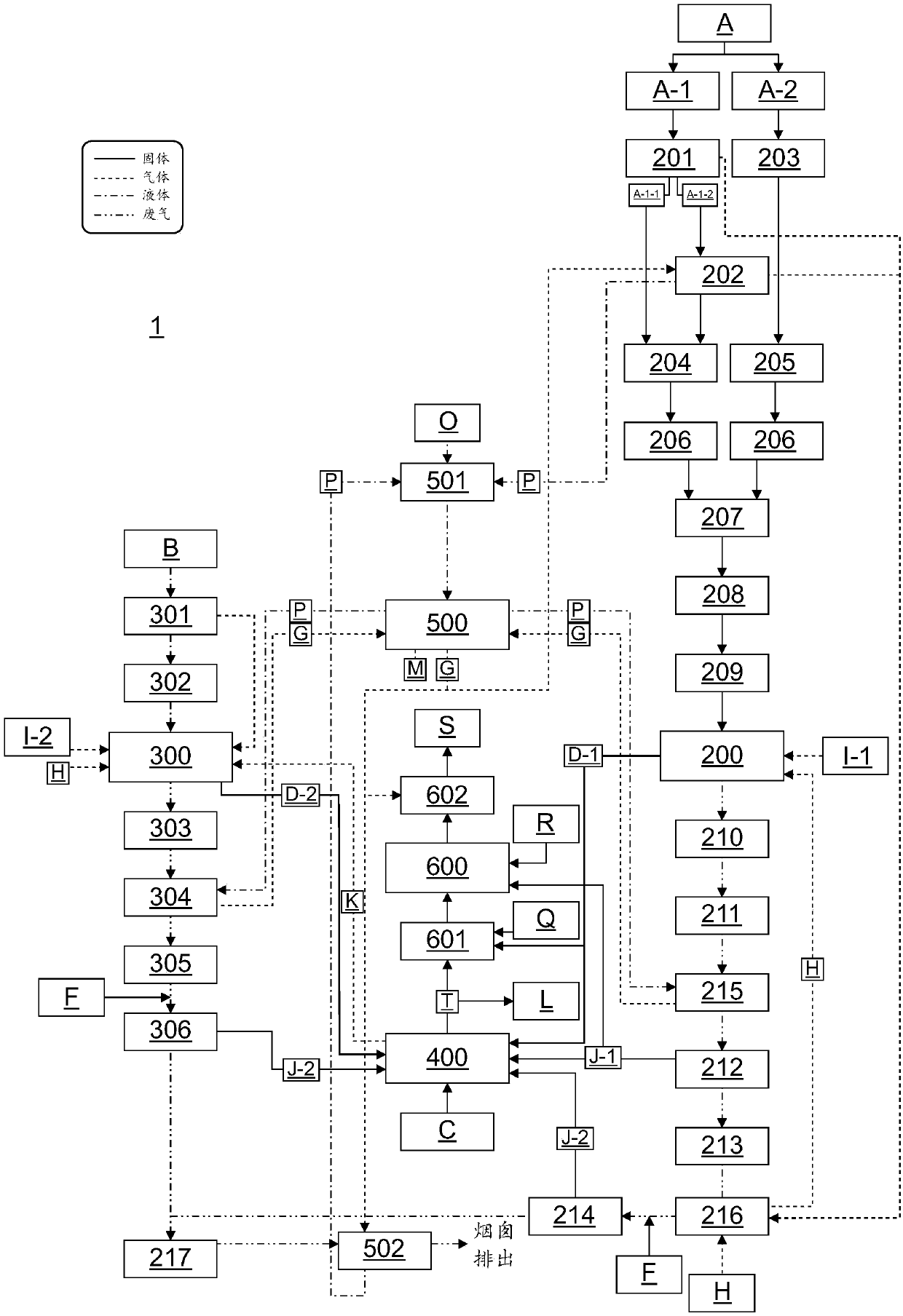

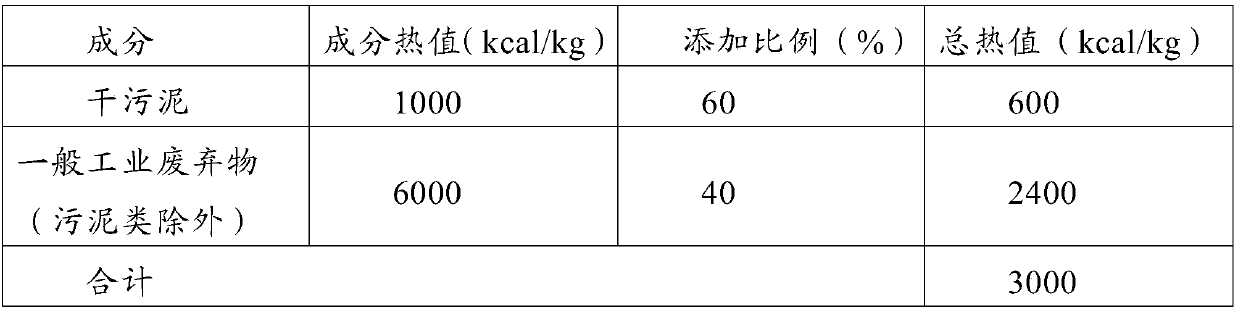

[0024] First, see figure 1 and cooperate figure 2As shown, the waste treatment and reuse method 1 includes a solid waste incineration treatment system 20 , a liquid waste incineration treatment system 30 , a high-temperature thermal fusion treatment system 40 , a steam-electric cogeneration system 50 and a cement product system 60 . And the solid waste incineration treatment system 20 is used to process general industrial waste (sludge) A-1 and general industrial waste (except sludge) A-2 of solid waste A, wherein, general industrial waste ( Sludge) A-1 includes organic sludge, inorganic sludge, non-hazardous oil sludge, sludge mixture, pulp and paper sludge, textile sludge or a combination thereof, general industrial waste (except sludge) A-2 includes waste ion exchange resins, solid waste resins other than waste ion exchange resins, waste plastic mixtures, waste rubber mixtures, waste wood pallets, waste wood mixtures, other general industrial wastes, waste dust collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com