Detachable discharge device of rice crust forming machine

A forming machine and crisper technology, which is applied in loading/unloading, food forming, transportation and packaging, etc. It can solve the problems of non-standard product size and weight, and low accuracy of manual feeding, so as to improve market competitiveness and structure Simple, accurate cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

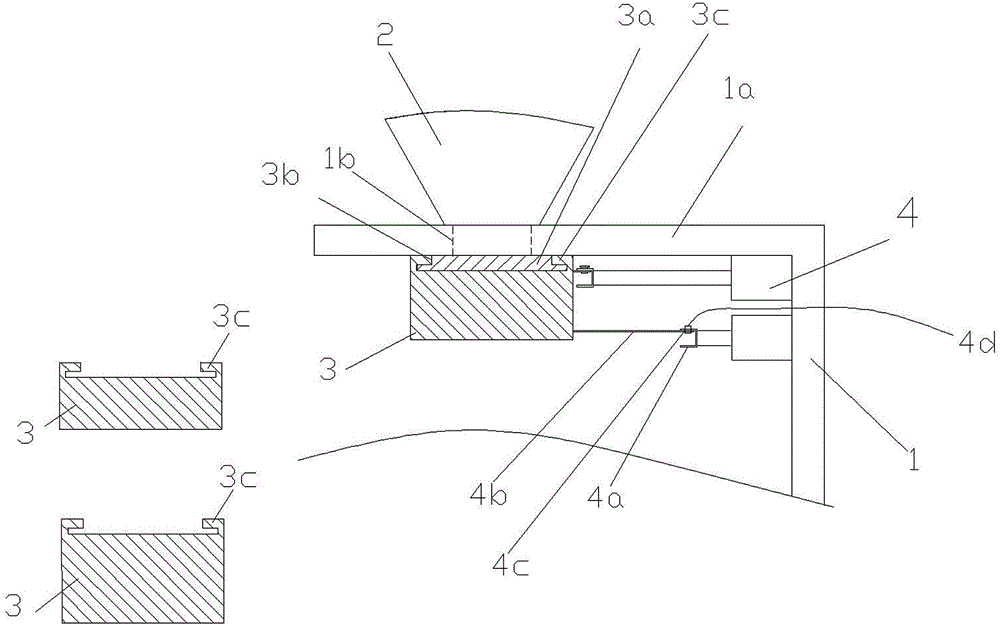

[0021] Such as figure 1 As shown, a detachable blanking device of a crispy rice forming machine, which includes a frame 1, is provided with a loading bin 2 on the upper workbench 1a of the frame 1, and is provided with a through hole 1b on the upper workbench 1a, One end of the through hole 1 b communicates with the charging bin 2 .

[0022] On the upper workbench 1a at the other end of the through hole 1b, a lower barrel connecting portion 3a is provided. The lower barrel connecting portion 3a is square and coaxial with the through hole 1b, and its diameter is larger than that of the through hole 1b.

[0023] A corresponding extension portion is symmetrically provided on the connection portion 3a, and the extension portion forms a groove 3b with the side wall of the connection portion 3a and the lower surface of the upper worktable 1a.

[0024] A set of lower barrels 3 with different volumes is provided, and the upper part of each lower barrel 3 is provided with an extension...

Embodiment 2

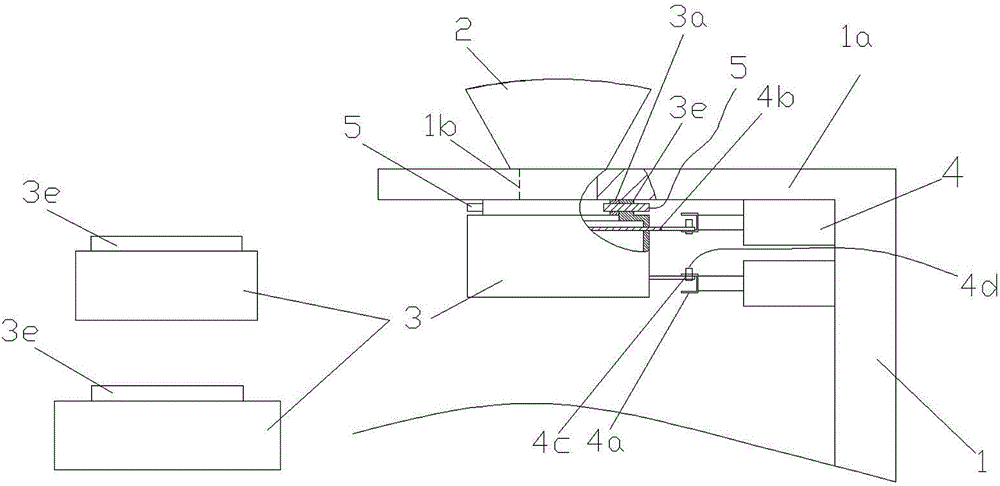

[0029] Such as figure 2 As shown, a detachable blanking device of a crispy rice forming machine, which includes a frame 1, is provided with a loading bin 2 on the upper workbench 1a of the frame 1, and is provided with a through hole 1b on the upper workbench 1a, One end of the through hole 1b communicates with the charging bin 2, and the upper workbench 1a at the other end of the through hole 1b is provided with a lower barrel connecting portion 3a, the through hole 1b is coaxial with the lower barrel connecting portion 3a, and the lower The diameter of the cartridge connection portion 3a is larger than the diameter of the through hole 1b.

[0030] A set of lower barrels 3 with different volumes is provided, and one end of each lower barrel 3 is provided with a sleeve portion 3e which can be sleeved on the outside of the lower barrel connection portion 3a along the axial direction. A pair of connecting holes are respectively symmetrically arranged on the lower barrel connec...

Embodiment 3

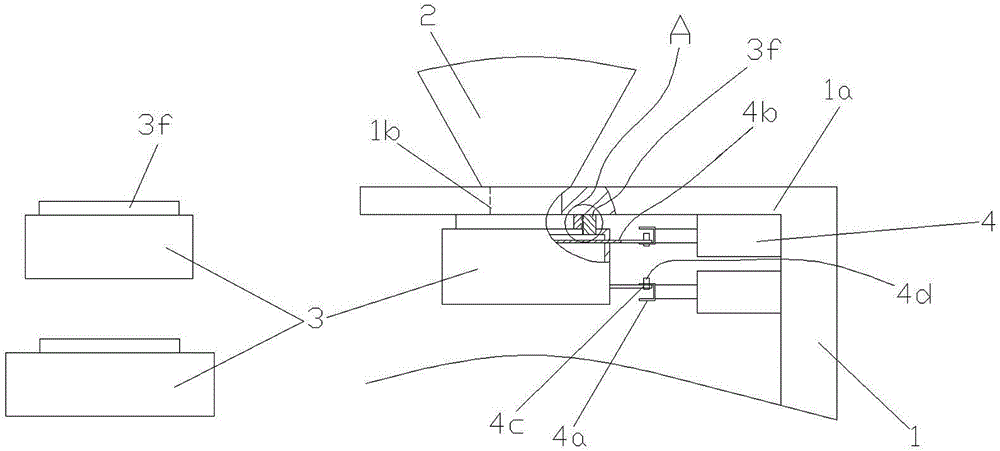

[0035] Such as image 3 , 4 As shown, a detachable unloading device of a crispy rice forming machine, which includes a frame 1, is provided with a loading bin 2 on the upper workbench 1a of the frame 1, and is provided with a through hole 1b on the upper workbench 1a, One end of the through hole 1b communicates with the loading bin 2, and a cylindrical lower material cylinder connecting portion 3a is provided on the upper workbench 1a at the other end of the through hole 1b, and the through hole 1b is connected to the lower material cylinder connecting portion 3a. Coaxial, and the diameter of the lower barrel connecting portion 3a is larger than the diameter of the through hole 1b, and the outer wall of the lower barrel connecting portion 3a is also provided with threads 6 .

[0036] A group of lower barrels 3 with different volumes is provided, and one end of each lower barrel 3 is provided with a threaded sleeve 3f matched with the thread 6 on the lower barrel connection po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com