An optimized blanking method for multi-size plate rectangular parts considering machinability

A rectangular part and machinability technology, applied in the field of optimized blanking of rectangular parts, can solve the problems of low material utilization rate, slow cutting speed, shortening, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

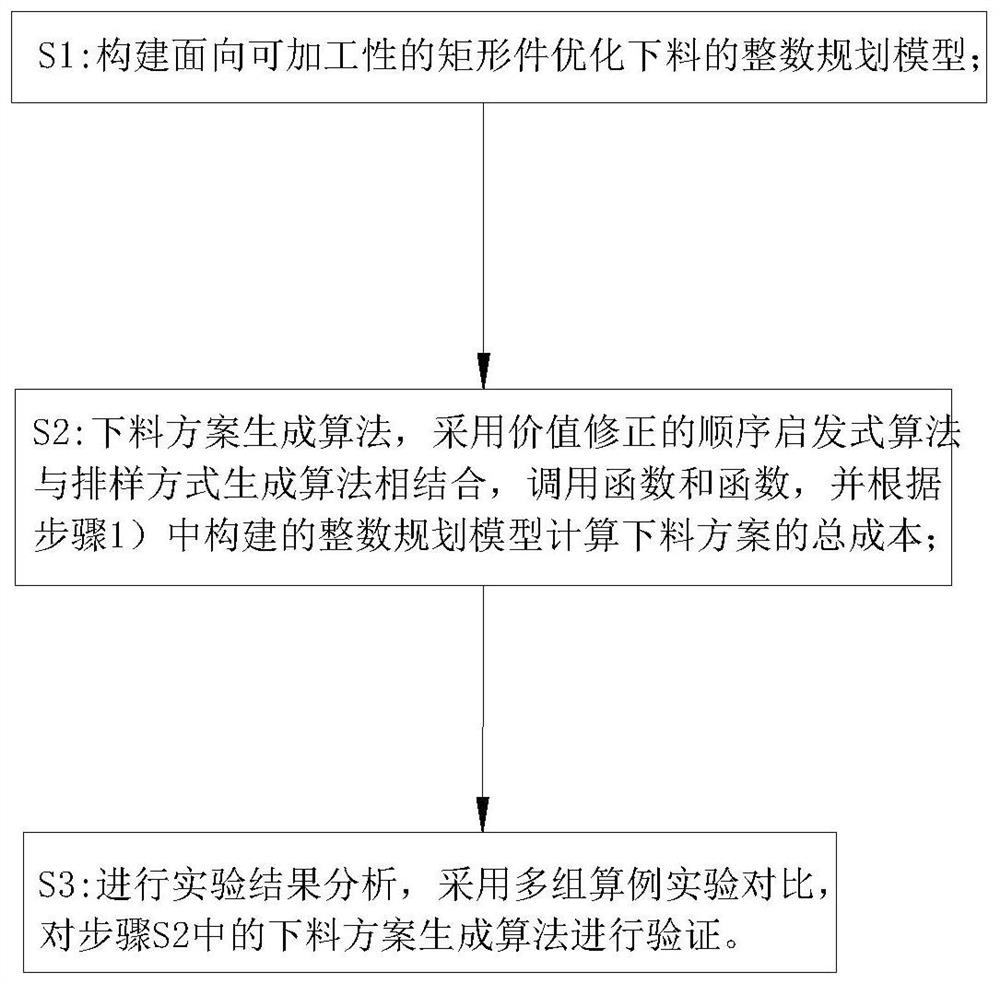

[0030] Embodiment: a method for optimizing the blanking of multi-size plate rectangular parts for considering machinability, such as figure 1 shown, including the following steps:

[0031] S1. Constructing an integer programming model for machinability-oriented rectangular parts optimized blanking, for n kinds of length L j , with a width of W j , the supply is D j (where j=1,...,n) cut out m kinds of plates with a length of l according to the requirements of the production process i , with a width of w i , the demand is d i (wherein i=1,...,m) of the rectangular piece, construct the following integer programming model:

[0032]

[0033]

[0034]

[0035]

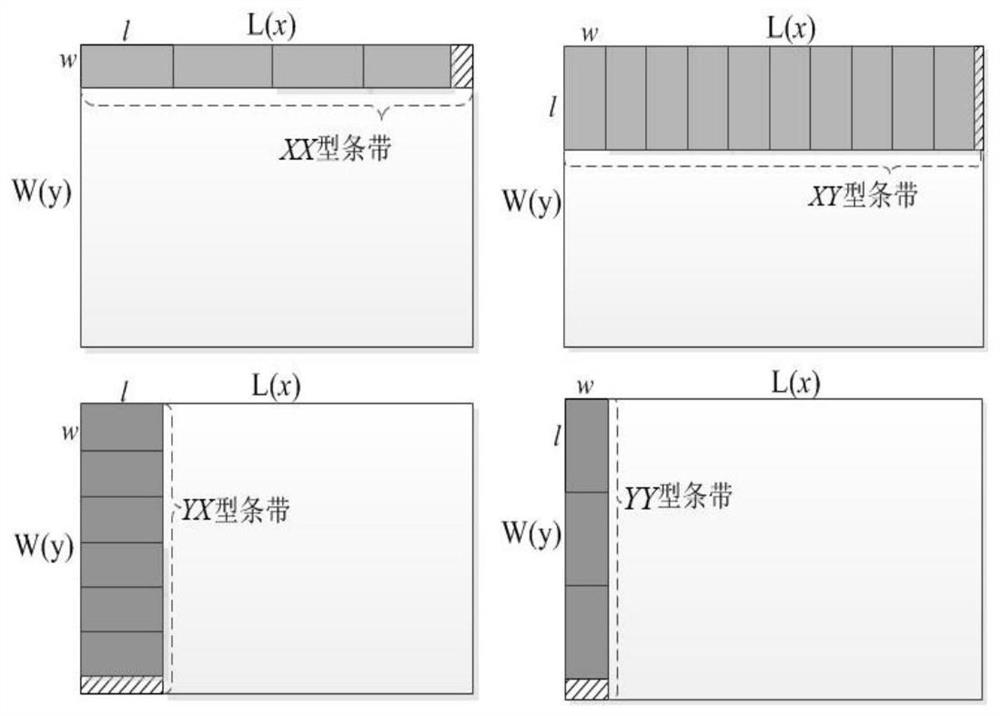

[0036] Among them, K represents the number of layout methods of the blanking plan, Z represents the production cost, and d i is demand, S k is the material cost consumed, λP k is the cutting cost (where λ is the control parameter, P k is the cutting path length, the cutting cost is proportional to the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com