A high-energy laser fiber bundle and its manufacturing method

A technology of high-energy laser and optical fiber bundle, which is applied in the direction of optical fiber bundle, coupling of optical waveguide, fiber mechanical structure, etc., can solve problems such as temperature rise of optical fiber bundle, achieve the effect of reducing stress, reducing optical fiber transmission loss, and easy to clean dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

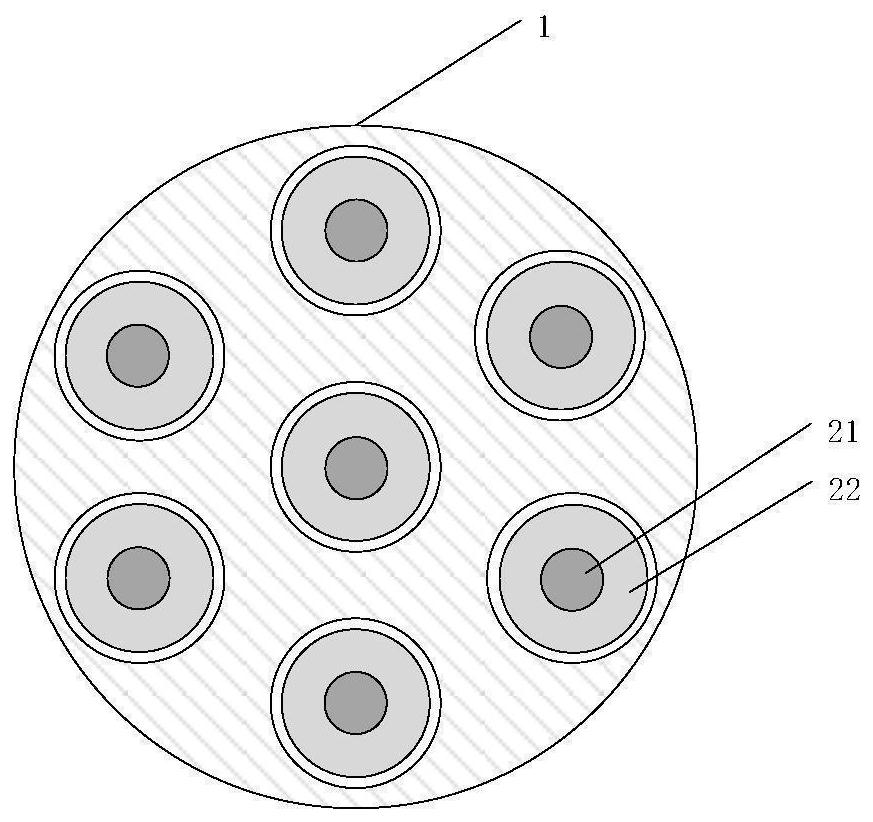

[0026] In the figure: 1—microporous glass plate; 2—transmission optical fiber, 21—fiber core, 22—fiber cladding, 23—fiber coating; 3—optical fiber bundle protective layer; 4—thermal silicone grease; 5—ultraviolet Curing glue sealing surface; 6-laser.

[0027] The invention relates to the technical field of fiber lasers and provides a high-energy laser fiber bundle. The optical fiber bundle includes three parts: optical fiber, packaging structure, and end face fixing structure. An optical fiber consists of a core, cladding and transparent coating. The encapsulation structure includes a non-cured heat-conducting medium filled inside the fiber bundle and a protective layer of the fiber bundle, wherein the heat-conducting medium has the function of reducing the stress between the optical fibers and reducing the transmission loss of the optical fiber. At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com