Combined oil damper stress performance testing device

An oil damper and testing device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of limited seismic performance of a single oil damper and lack of mechanical performance of a combined oil damper, so as to ensure the safety of the test process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

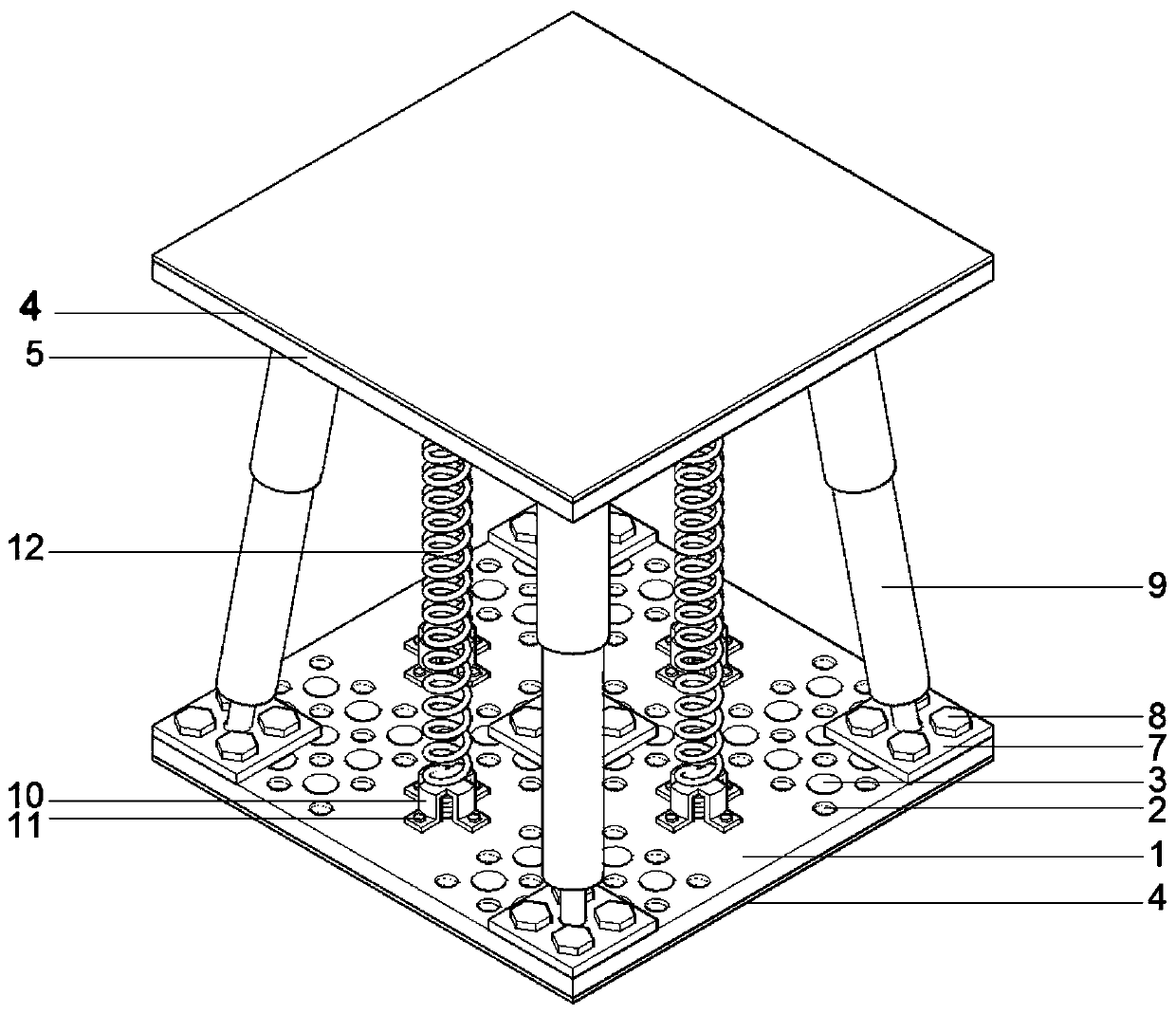

[0014] Specific implementation mode one: as Figure 1 ~ Figure 4 As shown, the present invention discloses a combined oil damper force performance testing device, including a bottom plate 1, a top plate 5, two anti-skid layers 4, four springs 12 and five oil dampers 9; the bottom plate 1 and The top plate 5 is a cuboid plate, the bottom of the bottom plate 1 and the top of the top plate 5 are provided with an anti-skid layer 4, the bottom plate 1 and the top plate 5 are elastically connected by four springs 12 and five oil dampers 9, and the five oil dampers 9 are arranged in the middle and four corners of the bottom plate 1 and the top plate 5 respectively, and the four springs 12 are arranged in a rectangular shape and alternately arranged with the four oil dampers 9 arranged in the corners.

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment is a further description of Embodiment 1. Both the bottom plate 1 and the top plate 5 are steel plates.

specific Embodiment approach 3

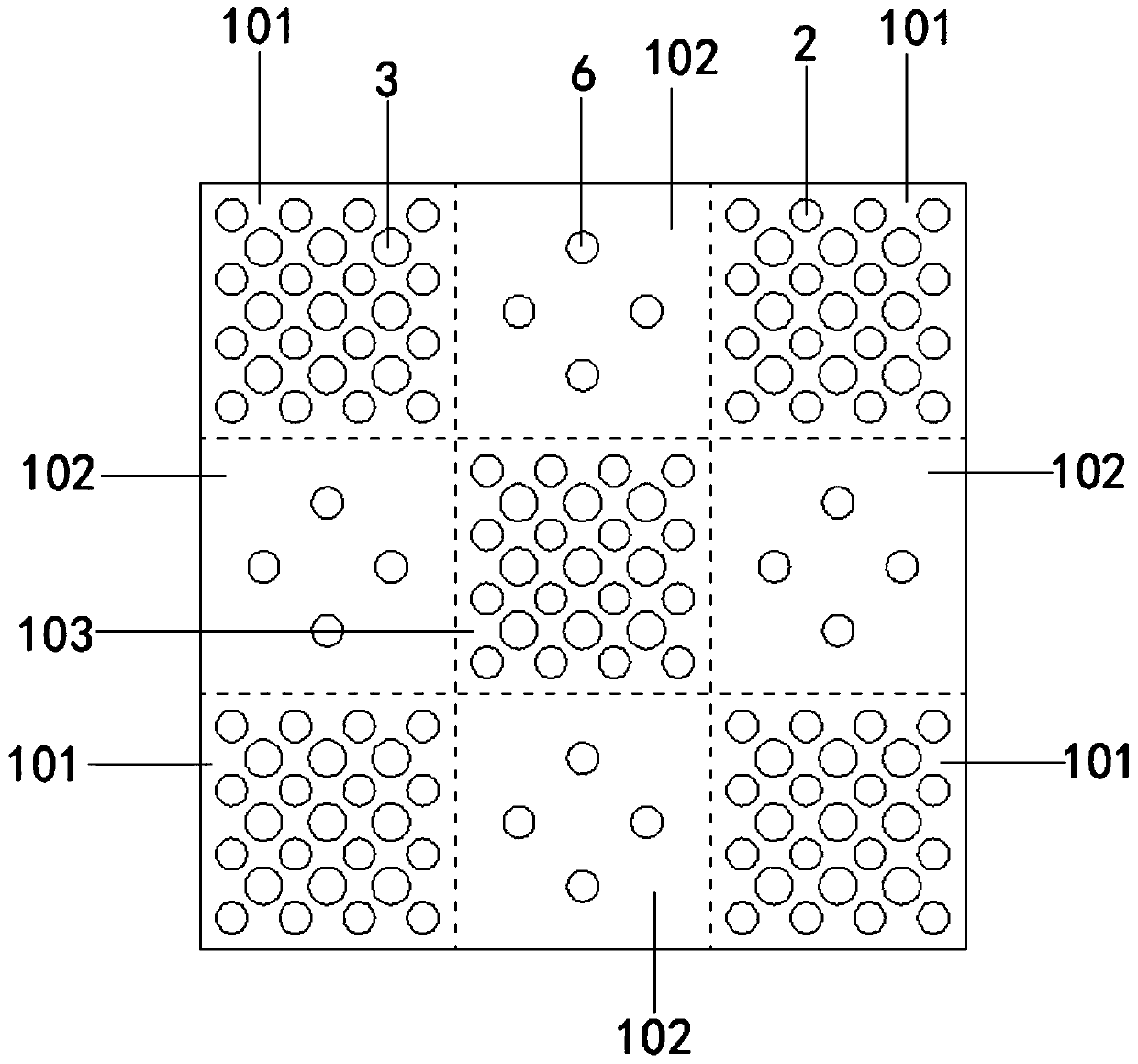

[0016] Specific implementation mode three: as figure 1 , 2 As shown, this embodiment is a further description of Embodiment 2. The opposite surfaces of the bottom plate 1 and the top plate 5 are equally divided into nine areas, and the nine areas include the middle area 103, the four corner areas 101 and Four side regions 102, the middle region 103 and the four corner regions 101 are all provided with a plurality of (nine) hemispherical grooves 3 and a plurality of (sixteen) base bolt holes 2, and the plurality (nine) 1) hemispherical grooves 3 and multiple (sixteen) base bolt holes 2 are arranged in a rectangular array and multiple (nine) hemispherical grooves 3 and multiple (sixteen) base bolt holes 2 one by one Arranged alternately, multiple (four) spring bolt holes 6 are provided in the middle of each of the four side regions 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com