Device and method for detecting hardness of spherical cover part

A detection device and detection method technology, applied in the direction of measuring device, testing material hardness, strength characteristics, etc., can solve the problems of inapplicability of hardness detection device, difficult to fix position, difficult placement of parts, etc., to achieve convenient adjustment, convenient operation, improved The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

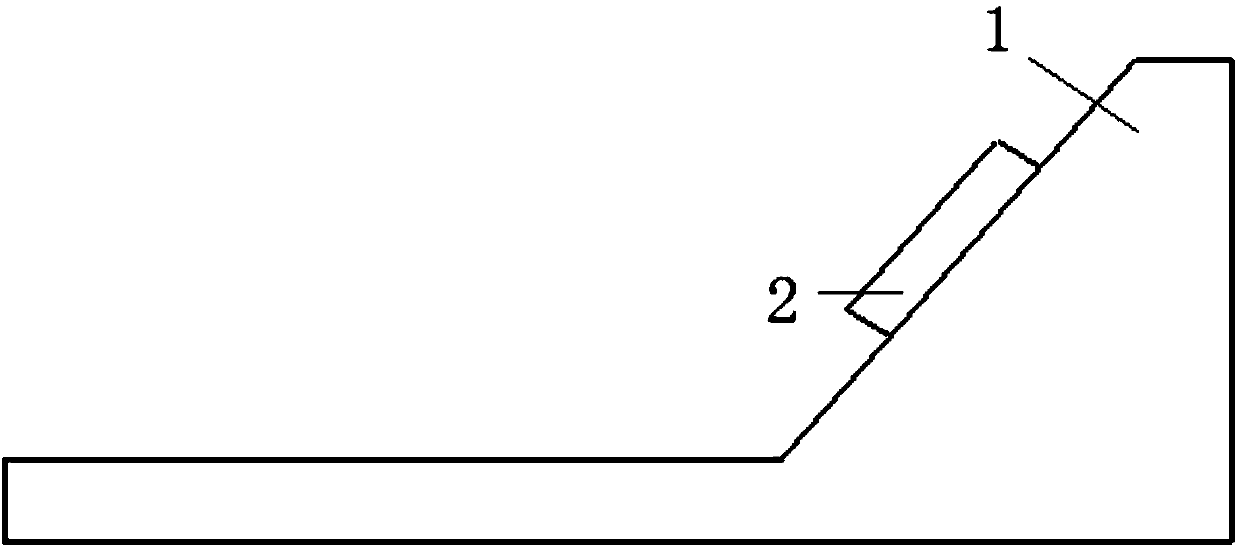

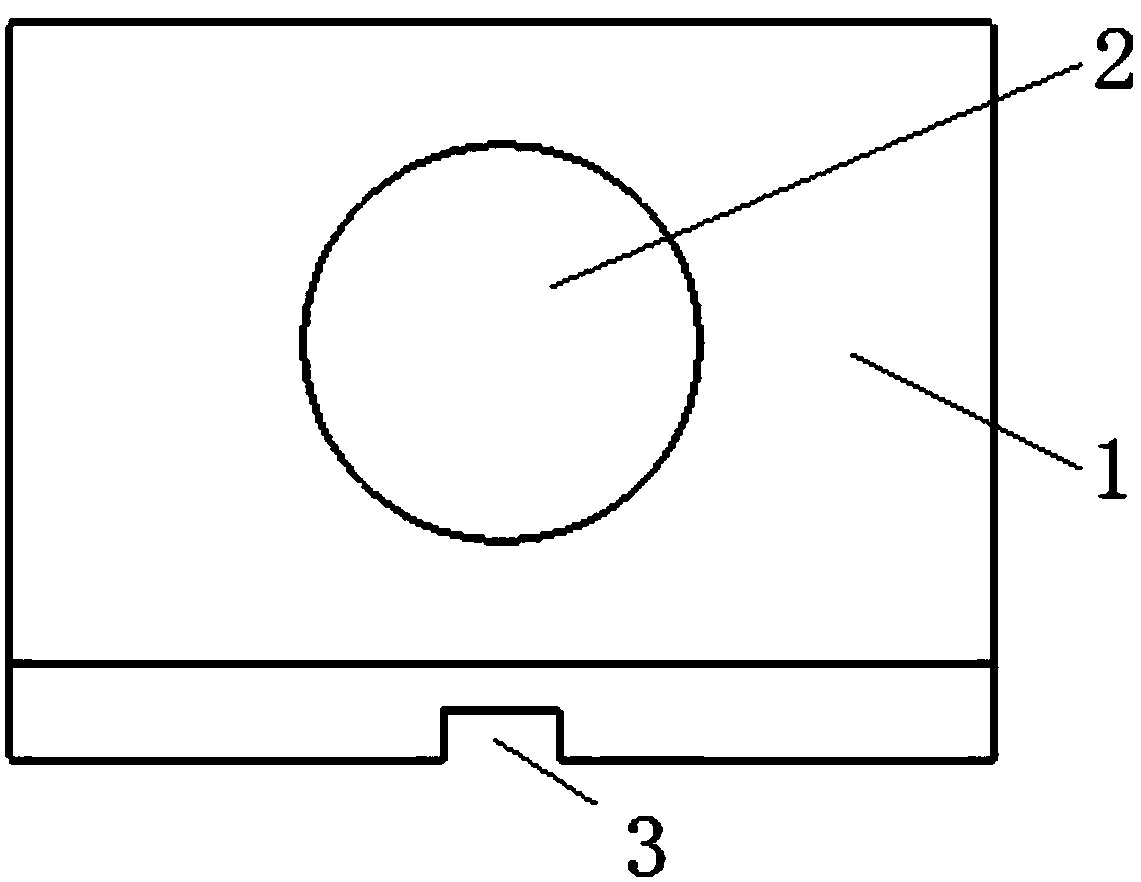

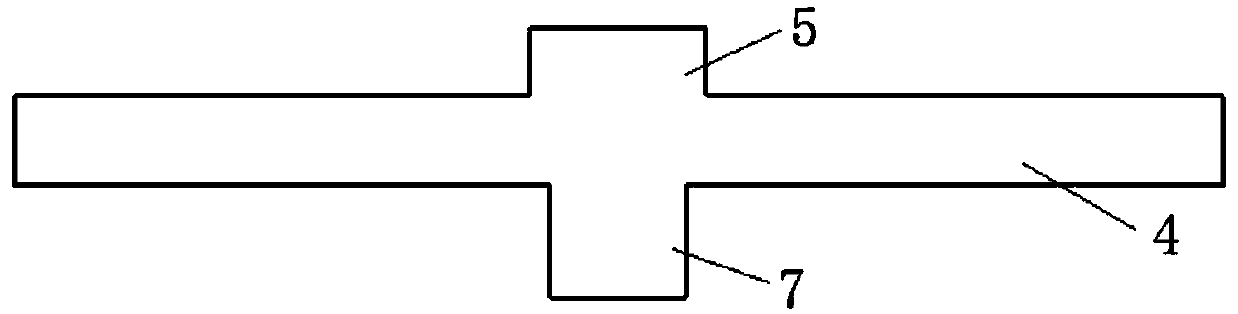

[0038] refer to figure 1 and figure 2 , a spherical cover part hardness testing device includes a hardness testing machine 8, a tooling main body 1, a base 4 and a long compression rod 6, the long compression rod 6 is a telescopic rod, and the operator can adjust the position of the long compression rod 6 as required during the detection process. The length plays the role of adjusting the distance between the indenter and the spherical cover. The lower end of the tooling body 1 is provided with a chute 3, which is set on the central axis of the front and rear direction of the lower end of the tooling body 1, and runs through the entire bottom of the tooling body 1. , the main body 1 of the tooling is a stepped structure, the first step is a rectangular platform, the second step is a right-angled trapezoidal platform, the first step is a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com