Connecting structure for short joint and used for fuel cell system

A fuel cell system and connection structure technology, which is applied in the direction of fuel cells, fuel cell additives, hose connection devices, etc., can solve problems such as low degree of connection fastening, aging of joint glue, and air leakage at joints, etc., to achieve High degree of fastening, good sealing performance, avoiding the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

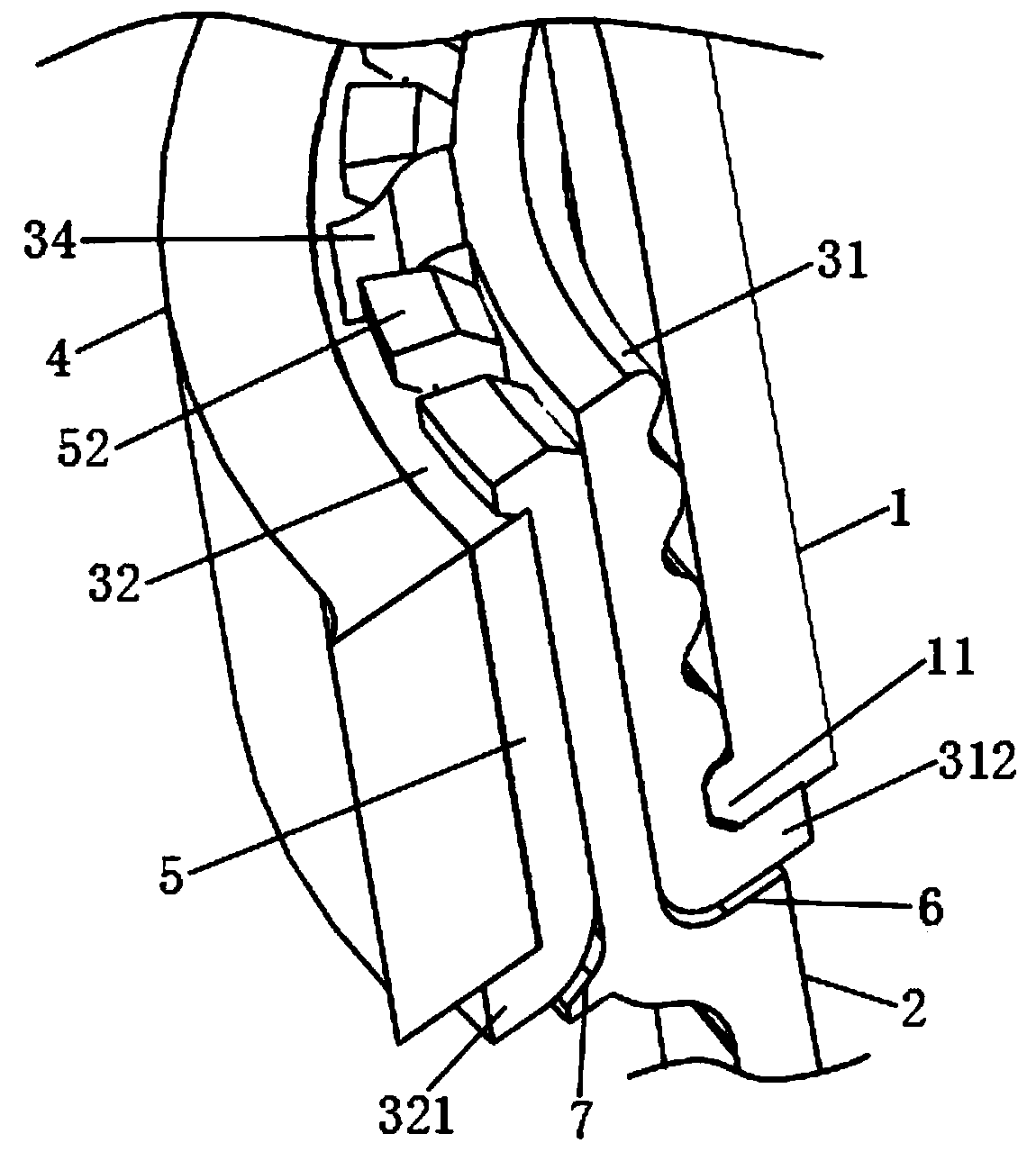

[0025] refer to Figure 1-Figure 4 , a connection structure for a short joint in a fuel cell system according to the present invention includes a first joint 1 and a second joint 2 ; and also includes a sealing joint 3 . Wherein, the sealing connector 3 includes an inner sleeve 31 and an outer sleeve 32, an insertion groove 33 is provided between the inner sleeve 31 and the outer sleeve 32, the first joint 1 is inserted into the inner sleeve 31, and the second joint 2 is inserted into the insertion joint. In the groove 33 , a locking member 4 is provided on the outer side of the sealing connection member 3 . Specifically, the locking member 4 is a hoop. The sealing conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com