Foldable operating hanging basket

A hanging basket and operating platform technology, applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc., can solve the problems of time-consuming, potential safety hazards, inconvenient transportation, etc. The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

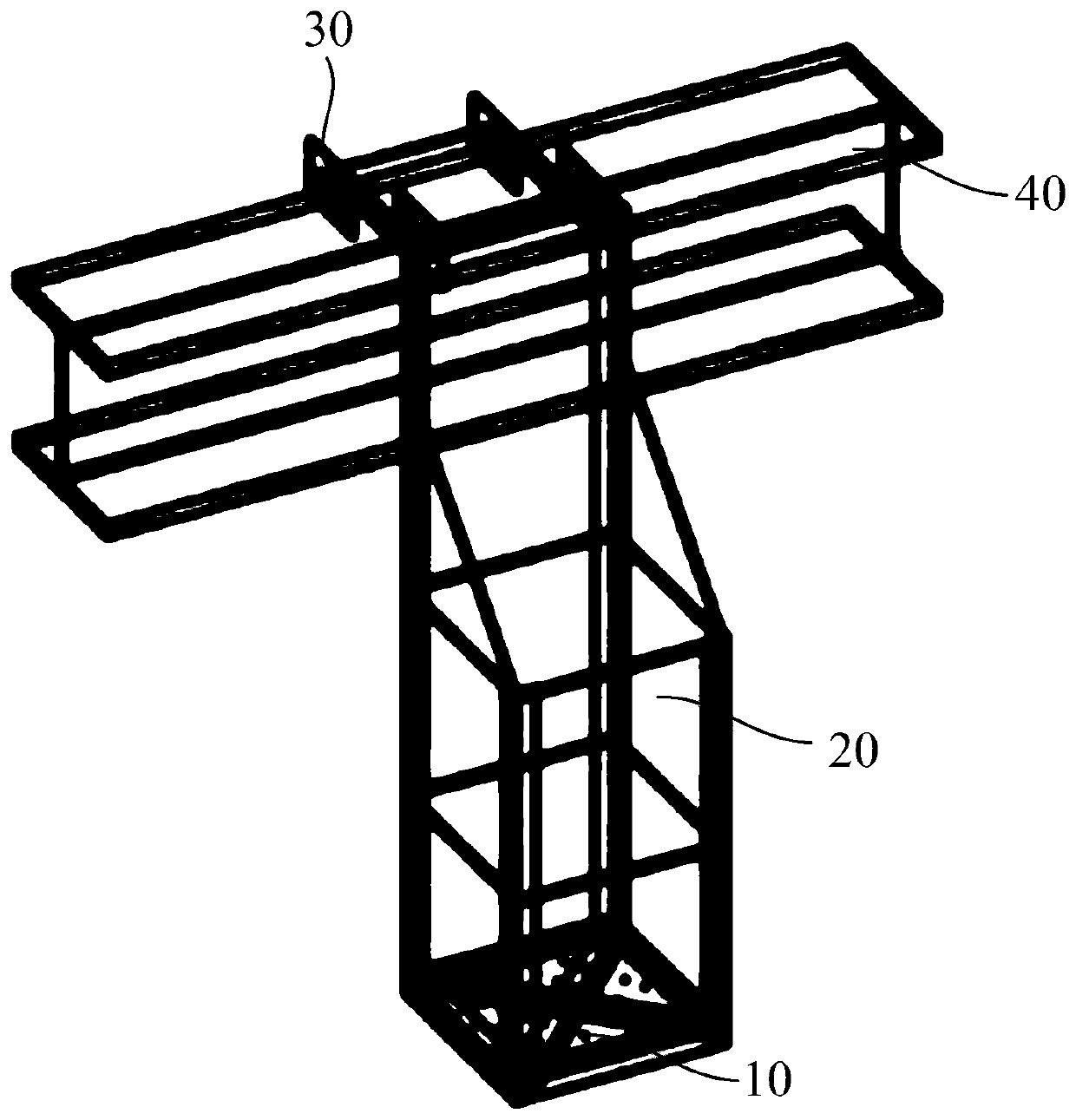

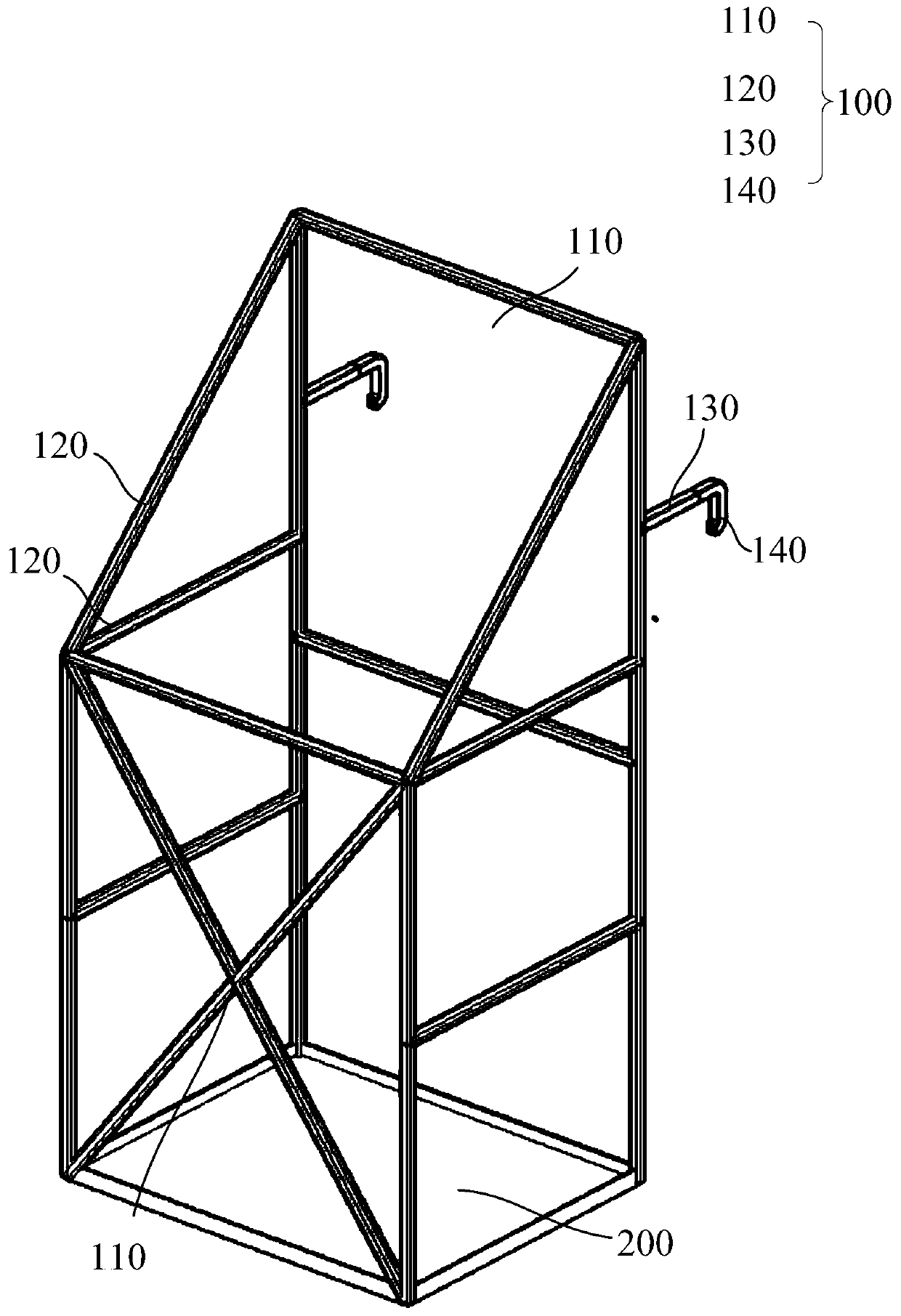

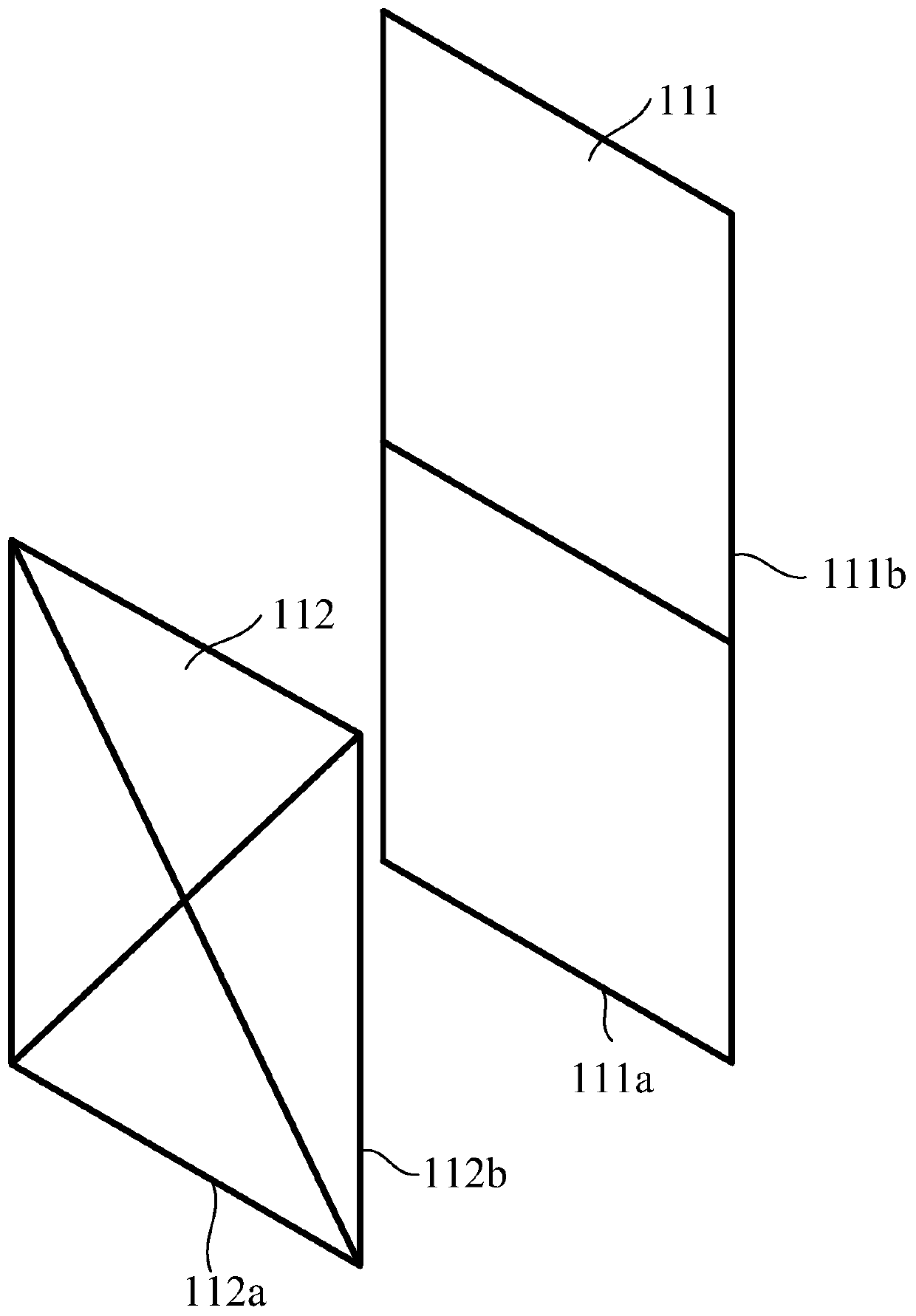

[0032] figure 1 It is a structural schematic diagram of an operating hanging basket. Such as figure 1 As shown, the existing operating platform includes an operating platform 10 and a frame 20, the operating platform 10 and the frame 20 are welded and connected, the frame 20 includes two steel plates and a plurality of steel bars, the steel plates are for example rectangular steel plates, two The two steel plates are arranged in parallel, and the long directions of the two are the same. The operation platform is welded on one end of the steel plate, and the two steel plates are welded and fixed by a plurality of steel bars. on the steel girder 40.

[0033] The inventor found that the material of the operating hanging basket is steel material, and the weight of steel plates, steel bars and other materials is too large, and the installation is inconvenient, so that the operating hanging basket must be made on site, which has the advantages of large volume, excessive weight, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com