Prefabricated light GFRP octagonal cable well and construction method thereof

A prefabricated, octagonal technology, used in construction, water conservancy projects, artificial islands, etc., can solve the problems of low construction efficiency and heavy weight, and achieve the effects of convenient construction, convenient transportation, and reduced material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

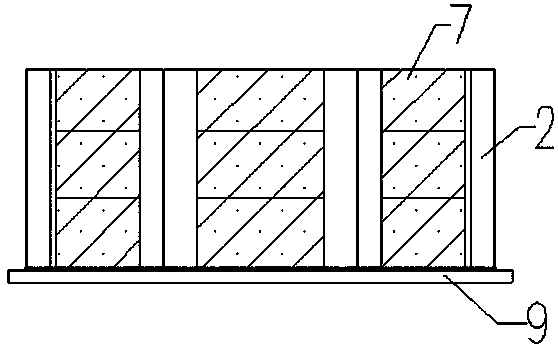

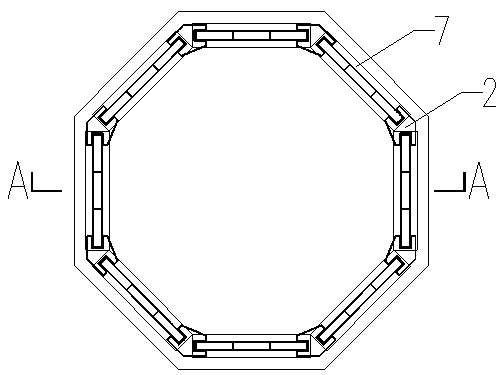

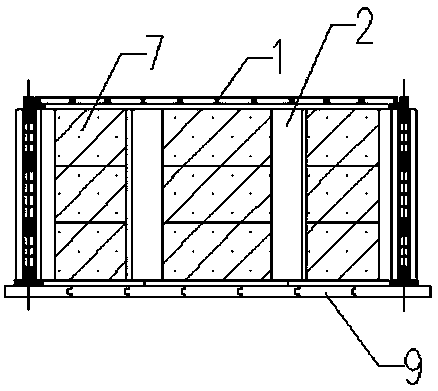

[0035] Such as figure 1 , figure 2 and image 3 As shown, a prefabricated light-weight GFRP octagonal cable shaft includes a cover plate 1, a column 2, a cover plate support 3, a baffle plate 7, an inverted T-shaped beam 8 and a bottom plate 9; the bottom plate 9 is passed through a bolt Or the fixing glue is fixed with eight inverted T-shaped beams 8, and the eight inverted T-shaped beams 8 are arranged in a regular octagon; columns 2 are arranged between adjacent two inverted T-shaped beams 8, and the grooves of the columns 2 are aligned with the inverted T-shaped beams 8 fit closely; baffles 7 are arranged between two adjacent columns 2, the bottom ends of baffles 7 are fixed to the inverted T-shaped beams 8 through tongue-and-groove connections, and the top ends of baffles 7 are connected through tongue-and-groove connections It is fixed with the cover plate support 3; the cover plate support 3 is fixed with a cover plate 1 by bolts; the cover plate 1, column 2, cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com