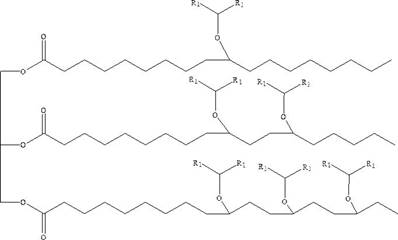

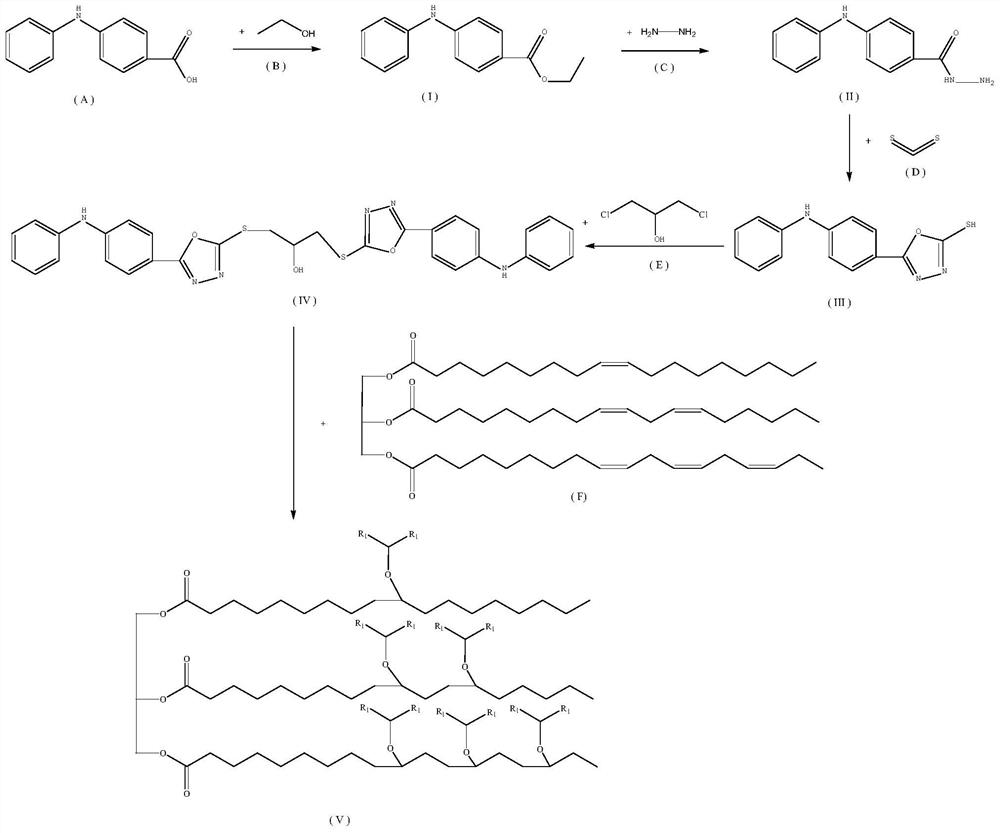

A kind of vegetable-based lubricating oil and preparation method thereof

A lubricating oil, plant-based technology, applied in the field of lubricating oil, can solve the problems of oxidation resistance, poor high temperature resistance, poor high temperature resistance, poor oxidation resistance, etc., and achieve high temperature resistance, excellent wear resistance, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

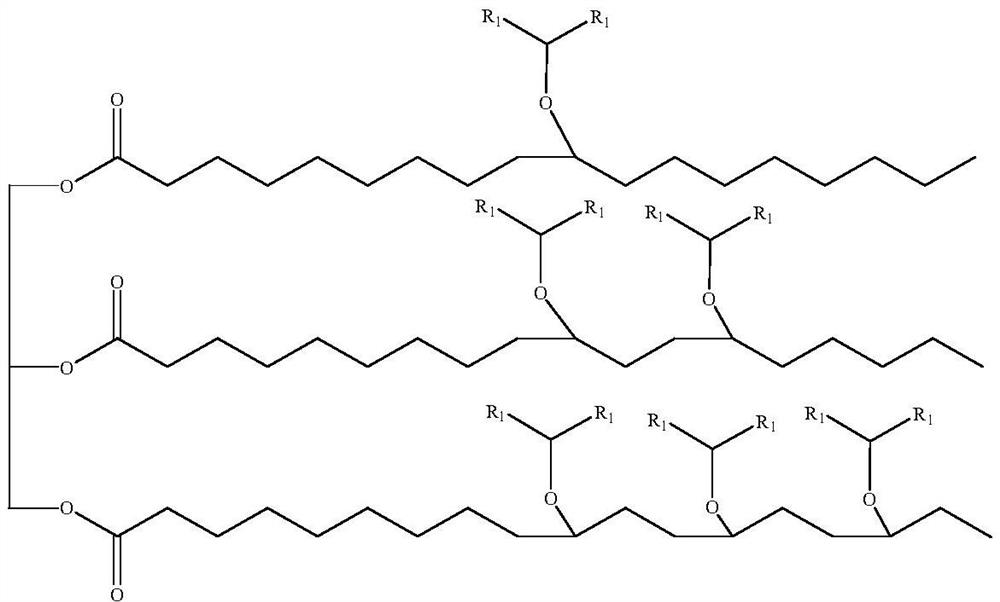

Method used

Image

Examples

Embodiment 1

[0043] Step (1) Add 1 mol of aminobenzoic acid derivative (A) to 10 mol of absolute ethanol (B) and stir, add 0.5 wt % sulfuric acid, heat under reflux at 120° C. for 5 h, pour into ice water after the reaction, and take the oil layer liquid , extracted and purified with ether, and dried in vacuo to obtain intermediate product I (IR: 3500cm -1 : -OH disappears; 3401cm -1 : Presence of secondary-NH; 1689cm -1 :-C=O exists).

[0044] Step (2) 1mol I was dissolved in 10mol absolute ethanol, added to the constant pressure dropping funnel, added dropwise to the absolute ethanol dissolved with 1mol hydrazine (C), heated to reflux for 18h, after the reaction was completed, the reaction was mixed. The liquid was poured into crushed ice and filtered to obtain a precipitate, which was washed with water and recrystallized from ethanol to obtain intermediate product II (IR: 3402 cm -1 : Presence and enhancement of secondary-NH; 3483cm -1 : Presence of primary-NH; 1689cm -1 :-C=O exis...

specific Embodiment 2-6

[0048] Specific embodiment 2-6, other is with specific embodiment 1, difference lies in the following table:

[0049]

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com