Design method of mix proportion of lc50~lc80 light weight high strength silicate ceramsite concrete

A technology of ceramsite concrete and silicate, which is applied in the field of concrete, can solve the problems that the accuracy of the amount of raw materials cannot be precisely controlled, the quality of concrete construction is difficult to guarantee, and the concrete strength is highly discrete, achieving small errors, strong applicability, and methods Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

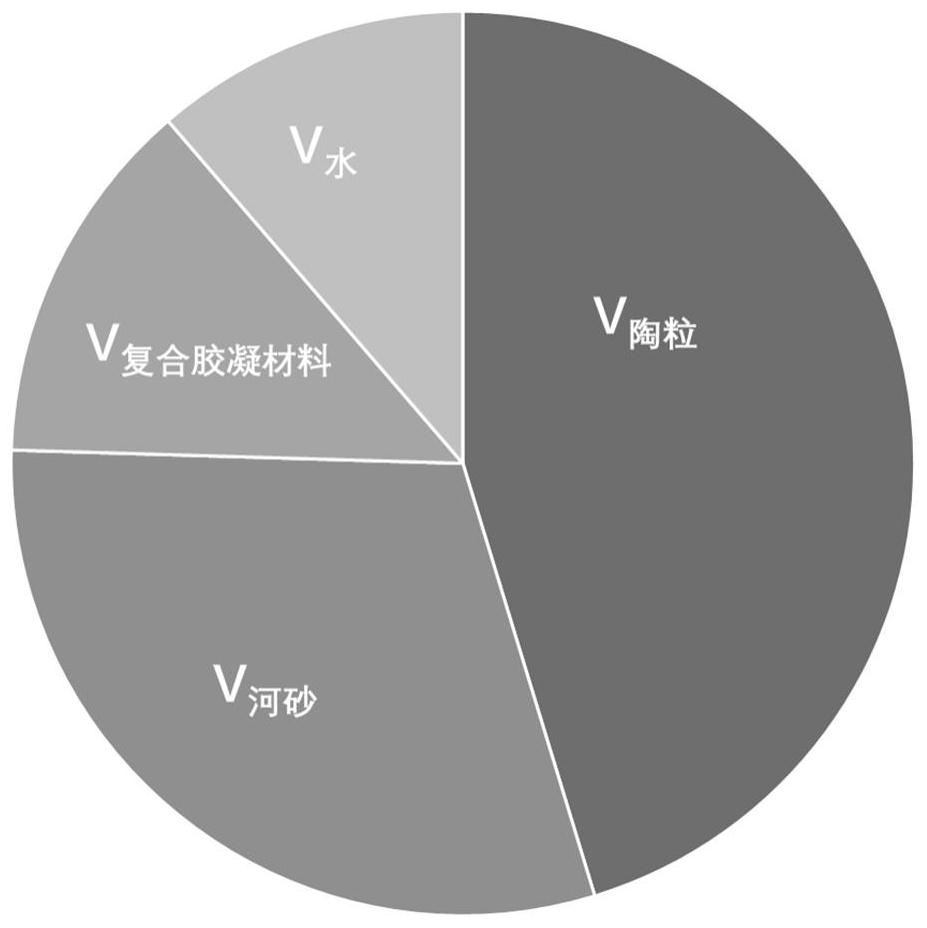

[0100] A design method for the mix ratio of LC50 lightweight high-strength silicate ceramsite concrete, wherein LC50 uses autoclaved shell ceramsite with an apparent density of 1600±100kg / m 3 , the cylinder compressive strength is greater than 10MPa, and the particle size is 5-16mm. The steps are as follows:

[0101] 1) Determine the trial mix strength of autoclaved silicate ceramsite concrete

[0102] P=1.19×P=1.19×50=59.5MPa

[0103] 2) According to the trial strength of autoclaved silicate ceramsite concrete, determine the absolute volume fraction V of the composite cementitious material of autoclaved silicate ceramsite concrete per cubic meter 复合胶凝材料

[0104] V 复合胶凝材料 =0.0008P+0.0881=0.008×59.5+0.0881=0.135m 3

[0105] In the formula, V 复合胶凝材料 =V 水泥 +V 硅灰 +V 粉煤灰 +V 矿渣

[0106] V 水泥 :V 硅灰 :V 粉煤灰 :V 矿渣 =1:0.070:0.063:0.054

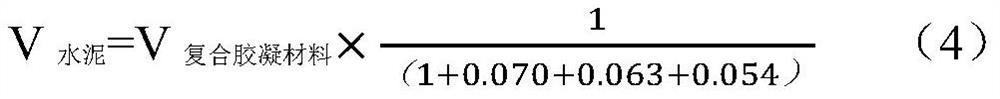

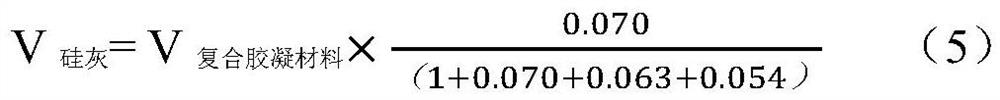

[0107] 3) Determine the absolute volume fraction V of each component of the composite gelling material 水泥 , V 硅灰 , V 粉煤灰 , V 矿渣

[...

Embodiment 2

[0141] A design method for the mix proportion of LC60 lightweight high-strength silicate ceramsite concrete, wherein the LC60 concrete uses shell ceramsite with an apparent density of 1700±85kg / m 3 , the cylinder compressive strength is greater than 12MPa, and the particle size is 5-16mm. The steps are as follows:

[0142] 1) Determine the trial mix strength of autoclaved silicate ceramsite concrete

[0143] P=1.15×P=1.15×60=69MPa

[0144] 2) According to the trial mix strength of autoclaved silicate ceramsite concrete, determine the absolute volume fraction V of the composite cementitious material of autoclaved silicate ceramsite concrete per cubic meter 复合胶凝材料

[0145] V 复合胶凝材料 =0.0008P+0.0881=0.008×69+0.0881=0.143m 3

[0146] In the formula, V 复合胶凝材料 =V 水泥 +V 硅灰 +V 粉煤灰 +V 矿渣

[0147] V 水泥 :V 硅灰 :V 粉煤灰 :V 矿渣 =1:0.070:0.063:0.054

[0148] 3) Determine the absolute volume fraction V of each component of the composite gelling material 水泥 , V 硅灰 , V 粉煤灰 , V 矿...

Embodiment 3

[0182] A design method for the mix proportion of LC70 lightweight high-strength shell silicate ceramsite concrete, wherein the LC70 concrete uses shell ceramsite with an apparent density of 1800±90kg / m 3 , the cylinder compressive strength is greater than 14MPa, and the particle size is 5-16mm. The steps are as follows:

[0183] 1) Determine the trial mix strength of autoclaved silicate ceramsite concrete

[0184] P=1.15×P=1.15×70=80.5MPa

[0185] 2) According to the trial strength of autoclaved silicate ceramsite concrete, determine the absolute volume fraction V of the composite cementitious material of autoclaved silicate ceramsite concrete per cubic meter 复合胶凝材料

[0186] V 复合胶凝材料 =0.0008P+0.0881=0.008×80.5+0.0881=0.153m 3

[0187] In the formula, V 复合胶凝材料 =V 水泥 +V 硅灰 +V 粉煤灰 +V 矿渣

[0188] V 水泥 :V 硅灰 :V 粉煤灰 :V 矿渣 =1:0.070:0.063:0.054

[0189] 3) Determine the absolute volume fraction V of each component of the composite gelling material 水泥 , V 硅灰 , V 粉煤灰 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com