A zigzag stepped variable section grid rudder structure based on drop zone control

A technology of grid structure and grid rudder, which is applied in space navigation equipment, space navigation vehicles, space vehicle guidance devices, etc., can solve the problem of high-speed re-entry and landing zone control sections that cannot meet the requirements of light weight and high efficiency, and cannot Use attitude control, poor aerodynamic shape and other problems to achieve the effect of shortening the production cycle, keeping the structure intact, and reducing the impact of the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

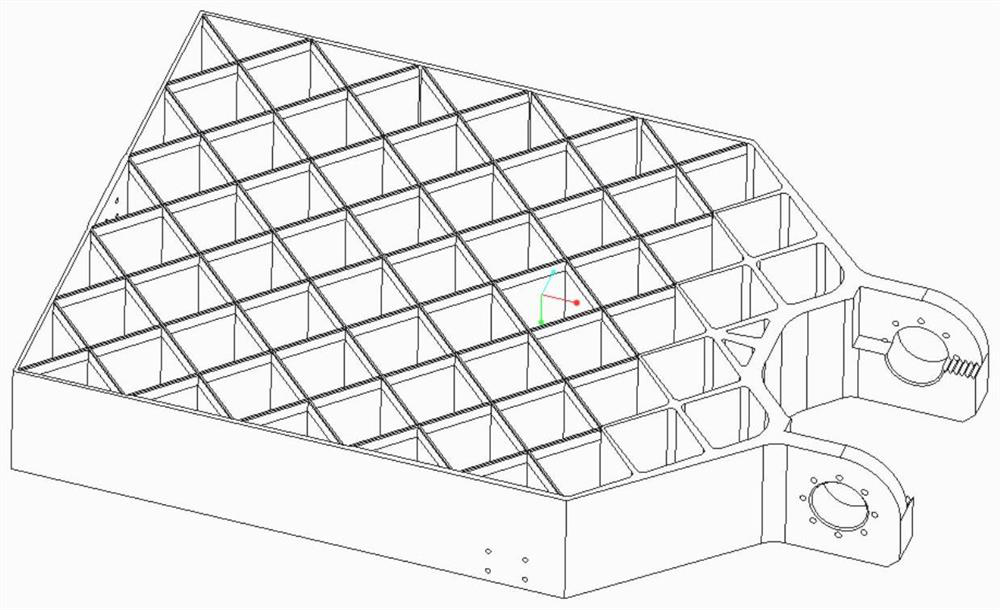

[0025] According to the realization requirements of the overall layout and to meet the requirements of load strength, stiffness, heat protection, etc., conduct preliminary coordination and parameter adjustment through engineering calculations and finite element analysis, ensure manufacturing accessibility through technological research, and carry out strength testing through static tests and functional tests. , functions and other overall requirements for indicator verification.

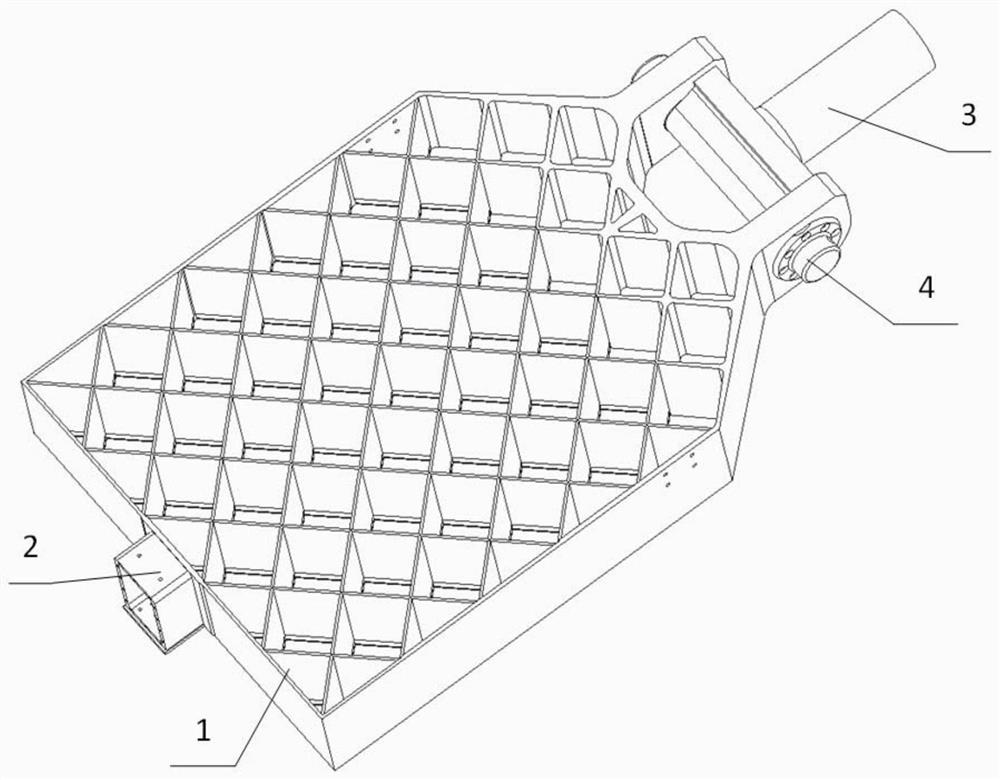

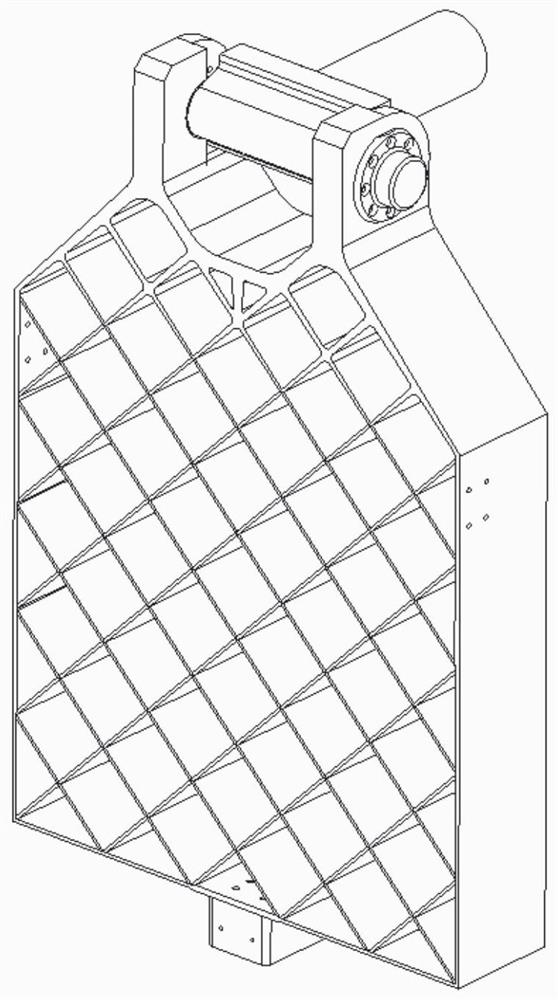

[0026] The present invention provides a sawtooth step-type variable-section grid rudder structure based on landing area control, comprising: a grid rudder body 1 , an explosive bolt box 2 , a special-shaped rotating shaft 3 , and an unfolding shaft 4 .

[0027] One end of the grid rudder body 1 is connected to the special-shaped rotating shaft 3 through the unfolding shaft 4; it is used to rotate around the rotating shaft when reentry and returning. The axis of the special-shaped rotating shaft 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com