Gravure plate roller and sleeve carving process thereof

A technology of gravure plate rolls and plate rolls, which is applied in the field of gravure plate rolls and their sleeve engraving technology, can solve problems such as insufficient ink, achieve the effect of sufficient ink and ensure the quality of printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

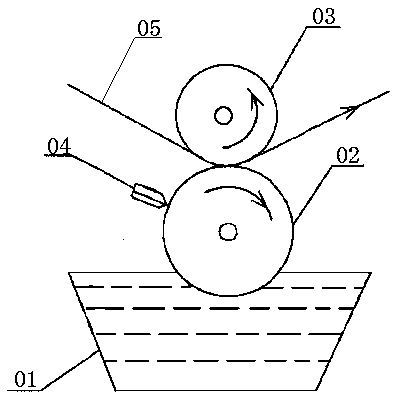

[0042] Such as figure 1 Shown: On the gravure printing machine, the lower version roller 02 is immersed in the ink tank 01 filled with ink, when the lower version roller 02 rotates, it drives the ink to rotate clockwise and adheres to the lower version roller 02, and the scraper 04 is located at the bottom of the lower version roller 02 On one side, above the ink tank 01, scrape off the excess ink on the lower version roller 02, that is, fill the ink in the cell of the lower version roller 02; print.

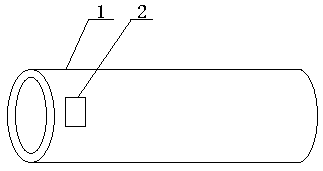

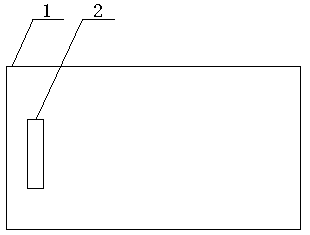

[0043] Such as figure 2 , image 3 , Figure 4 Shown: At the initial contact position between the scraper and the dots, that is, at the boundary of the graphic dots, the dots are not dense because the edges of the dots are not uniform, and the ink is directly scraped off with the scraper. During the downward movement of the scraper, it is easy to tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com