Novel 3D printer

A 3D printer, a new type of technology, applied in 3D object support structures, manufacturing tools, chemical instruments and methods, etc., can solve problems affecting the normal use of devices, leakage of printing powder, poor sealing, etc., to improve experience and ensure printing quality , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

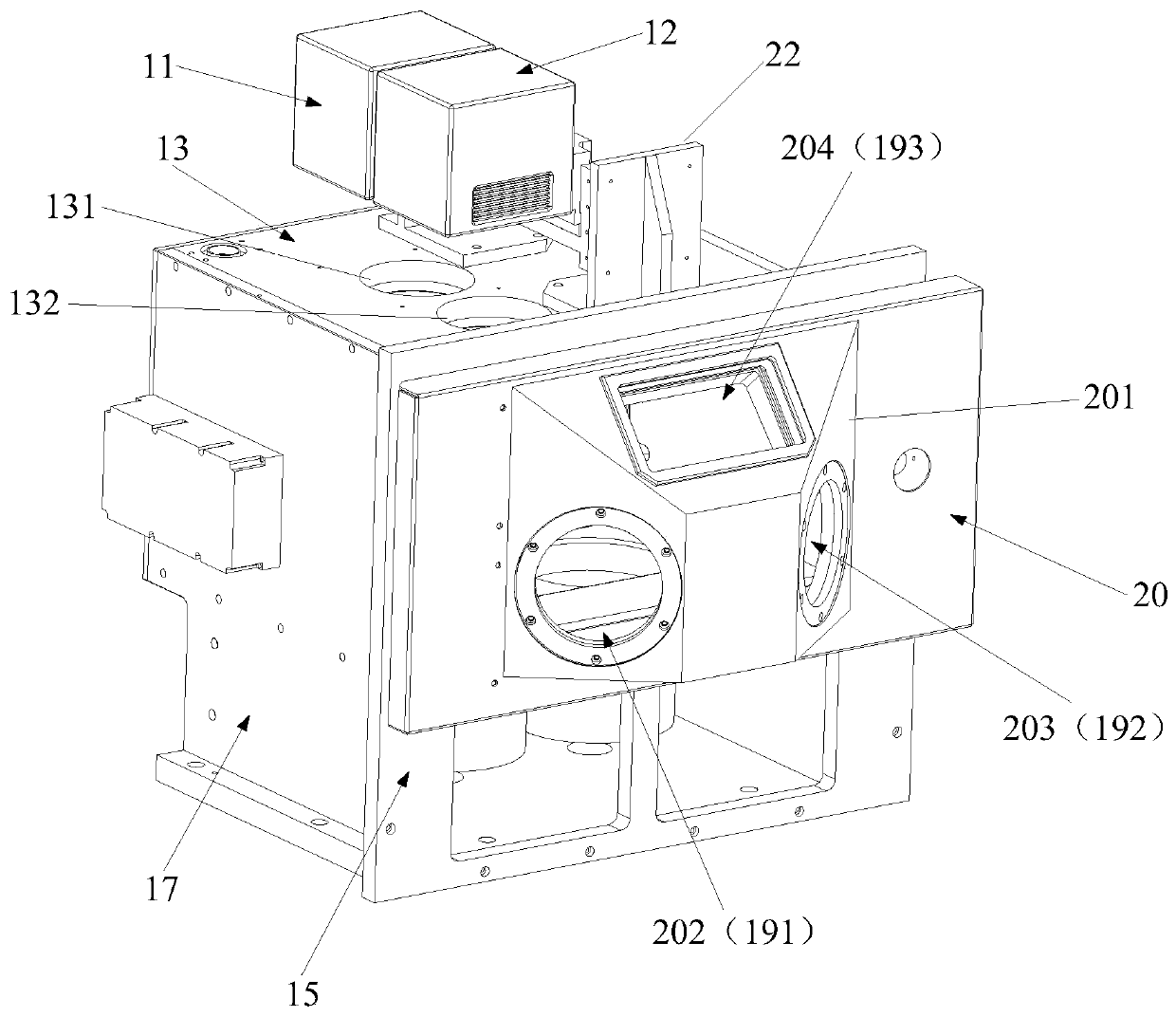

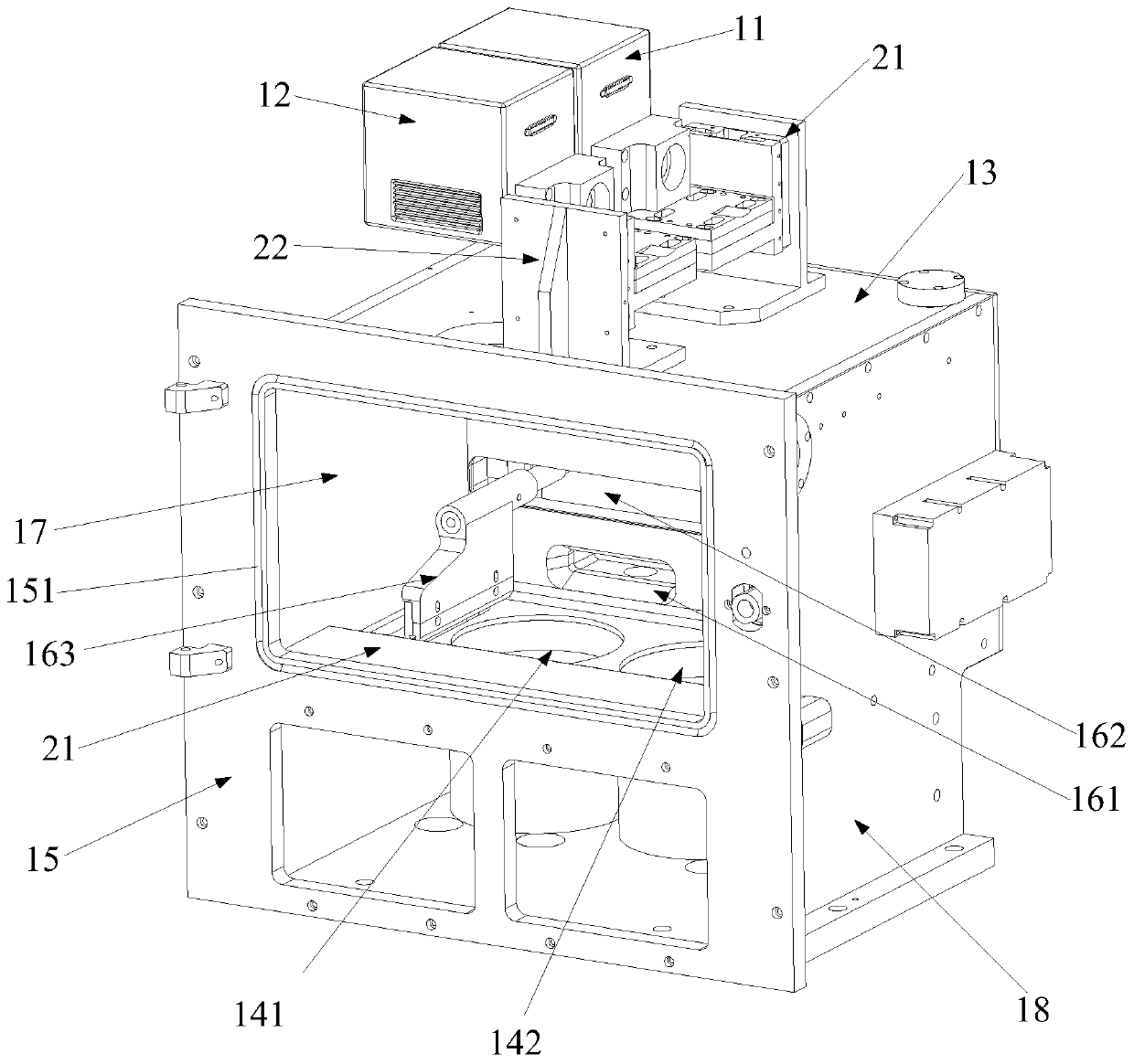

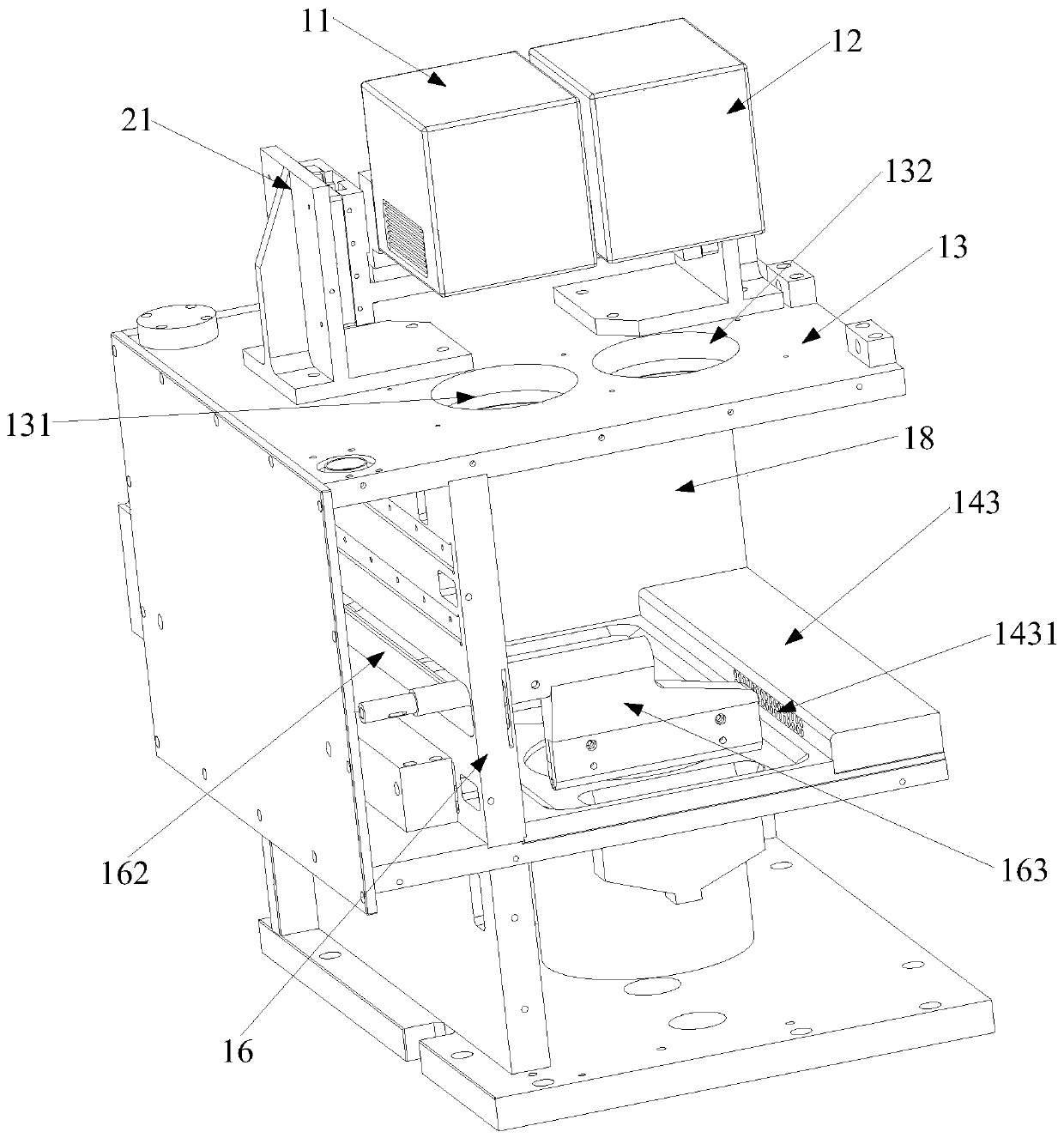

[0026] Such as Figure 1-9 As shown, the novel 3D printer includes a first vibrating mirror 11, a second vibrating mirror 12, a top plate 13, a bottom plate 14, a front side plate 15, a rear side plate 16, a left side plate 17, a right side plate 18, a scraper 163, a sealing A door 19 , a protective cover 20 , a first support portion 21 and a second support portion 22 .

[0027] In this embodiment, the top plate 13 , the bottom plate 14 , the front side plate 15 , the rear side plate 16 , the left side plate 17 and the right side plate 18 form a sealed cavity. It should be understood that in this example, 3D printing is performed in a sealed cavity.

[0028] In this embodiment, the rear side plate 16 is provided with an air outlet 161 communicating with the sealed cavity, wherein the rear side plate 16 is also provided with a slide groove 162 above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com