Continuous processing and production process of composite geotechnical drainage net

A technology of composite geotechnical and production technology, which is applied to nets, other household appliances, household appliances, etc., can solve the problems of increasing the number of defective products, cumbersome work, poor precision, etc., to increase output output, increase production output, and product quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

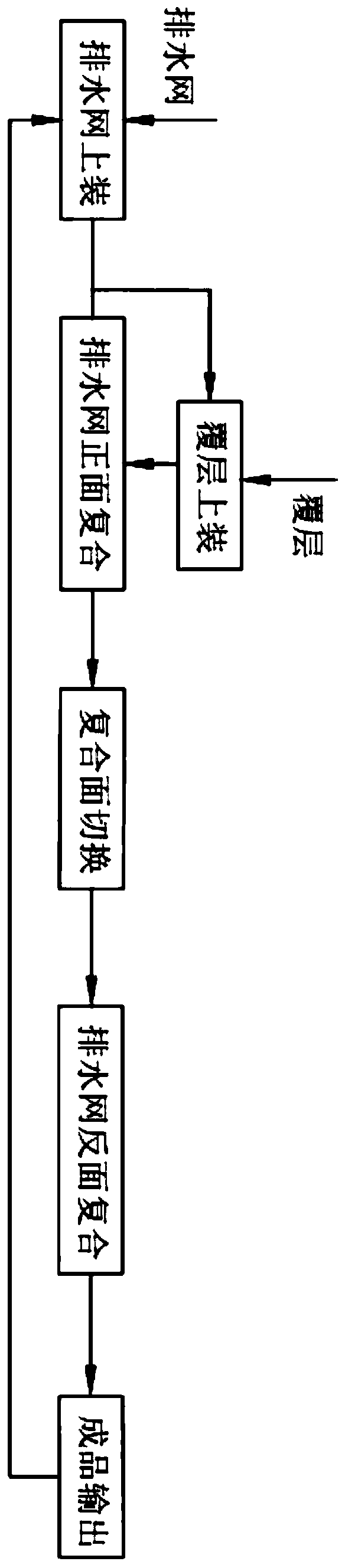

[0083] Such as figure 1 As shown, a composite geotechnical drainage network continuous processing production process, including:

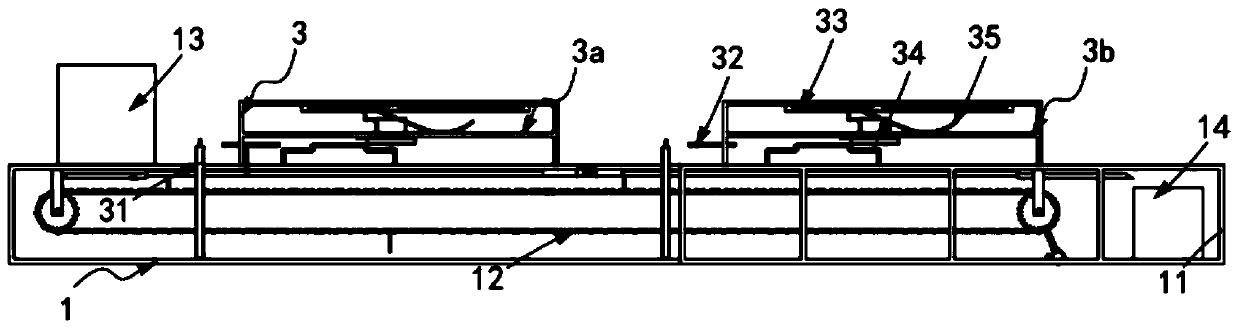

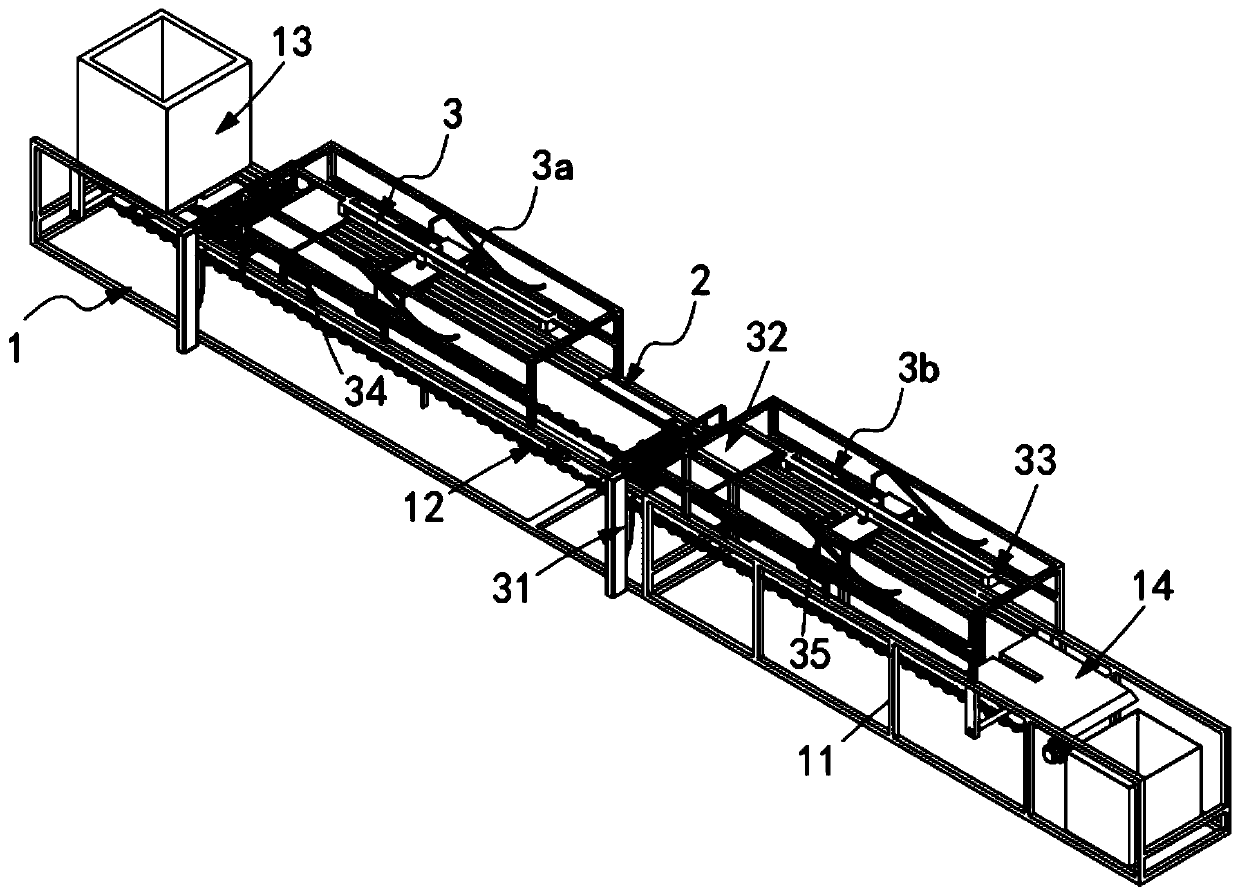

[0084] Step 1, installing the drainage nets, manually stacking several groups of drainage nets 10 in the support frame 133 along the vertical direction, starting the pushing component 12 to push the drainage nets 10 on the base 131;

[0085] Step 2, coating top-loading, manually placing the coating 20 on the support plate 322, and the pushing component 12 synchronously drives the coating top-loading component 32 under the work of pushing the drainage net 10 to transfer the coating 20 to the pressing component 342;

[0086] Step 3: The front side of the drainage net is compounded, and the drainage net 10 is driven to the bottom of the brushing assembly 31 for gluing work. After the gluing work is completed, it is continued to be sent to the drainage net 10 to align with the coating 20, and the driving component 33 receives the induction and drives t...

Embodiment 3

[0144] Such as Figure 27 , Figure 21 , Figure 25 and Figure 26 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0145] further, such as Figure 21 As shown, the flattening assembly 35 includes a pressing assembly 351 slidably arranged in the sliding groove 3411 of the mounting frame 341 along the vertical direction, a flattening assembly 352 arranged at the center of the cladding 20 and An adjusting assembly 353 for driving the pressing assembly 351 to move up and down in the vertical direction;

[0146] The pressing component 351 includes a pressing block 3511 with an I-shaped structure and an elastic unit e3512 for connecting the pressing block 3511 and the mounting frame 341; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com