Injection molding machine working condition monitoring system

A technology of working status monitoring and working status, applied in the field of intelligent monitoring equipment, can solve problems such as reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

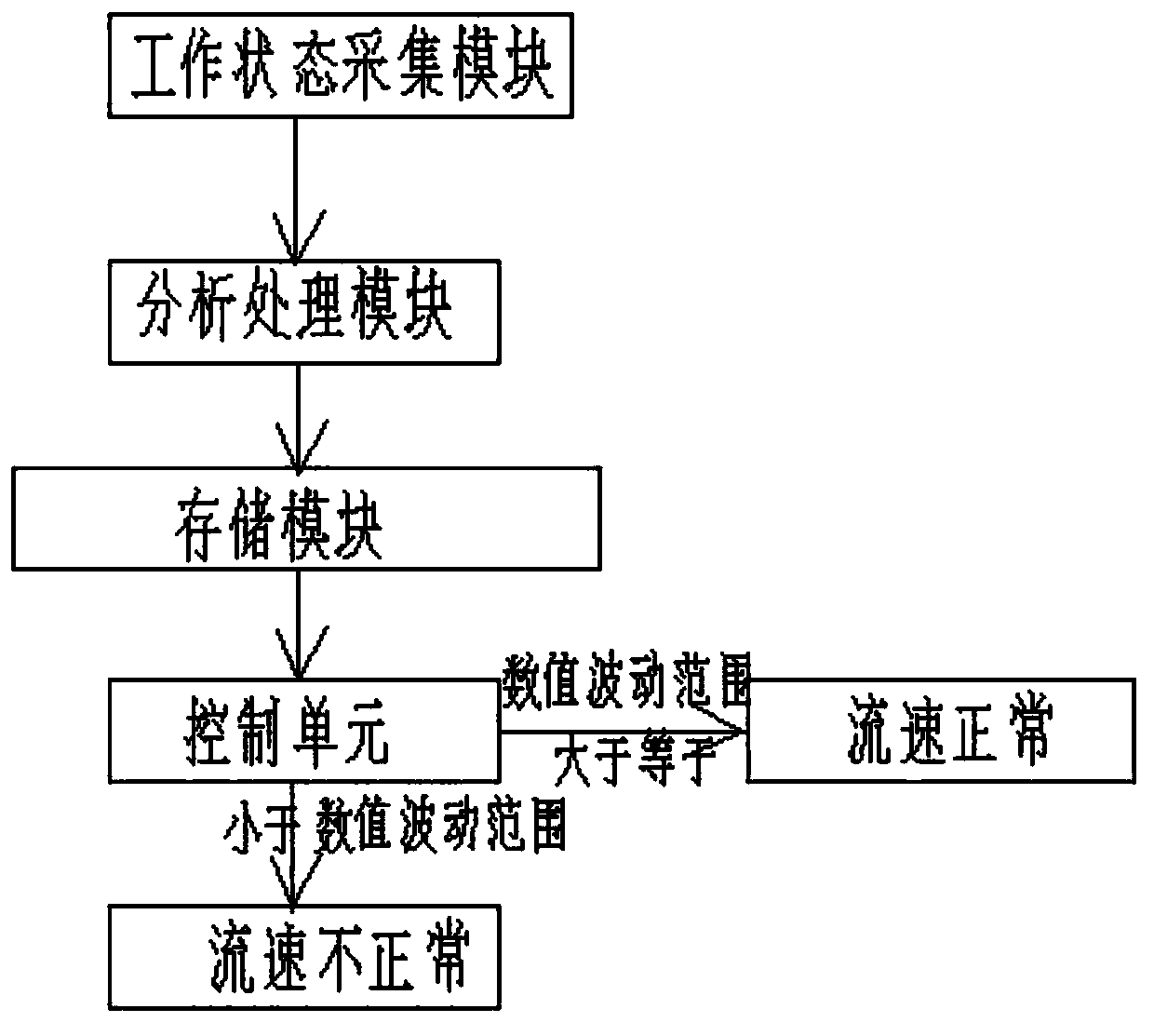

[0013] Such as figure 1 As shown, a working state monitoring system of an injection molding machine is characterized in that it includes a working state collection module, the working state collection module collects the working state of the injection molding machine in real time, and the working state collection module works the collected injection molding machine in real time The state information data is transmitted to the analysis processing module, and the analysis processing module will count the real-time speed information of the working state, and compare the statistical data information with the normal working state data information pre-stored in the storage module, and the comparison result will be Pass it to the control unit, and preset a numerical fluctuation range inside the control unit. If the compared data information is smaller than the above numerical fluc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com