Drilling positioning mechanism and drilling machine with mechanism

The technology of a positioning mechanism and a drilling machine is applied to the drilling machine. , In the field of drilling positioning mechanism, it can solve problems such as errors and inability to effectively guarantee drilling accuracy, and achieve the effects of stable and reliable movement, improved drilling accuracy, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

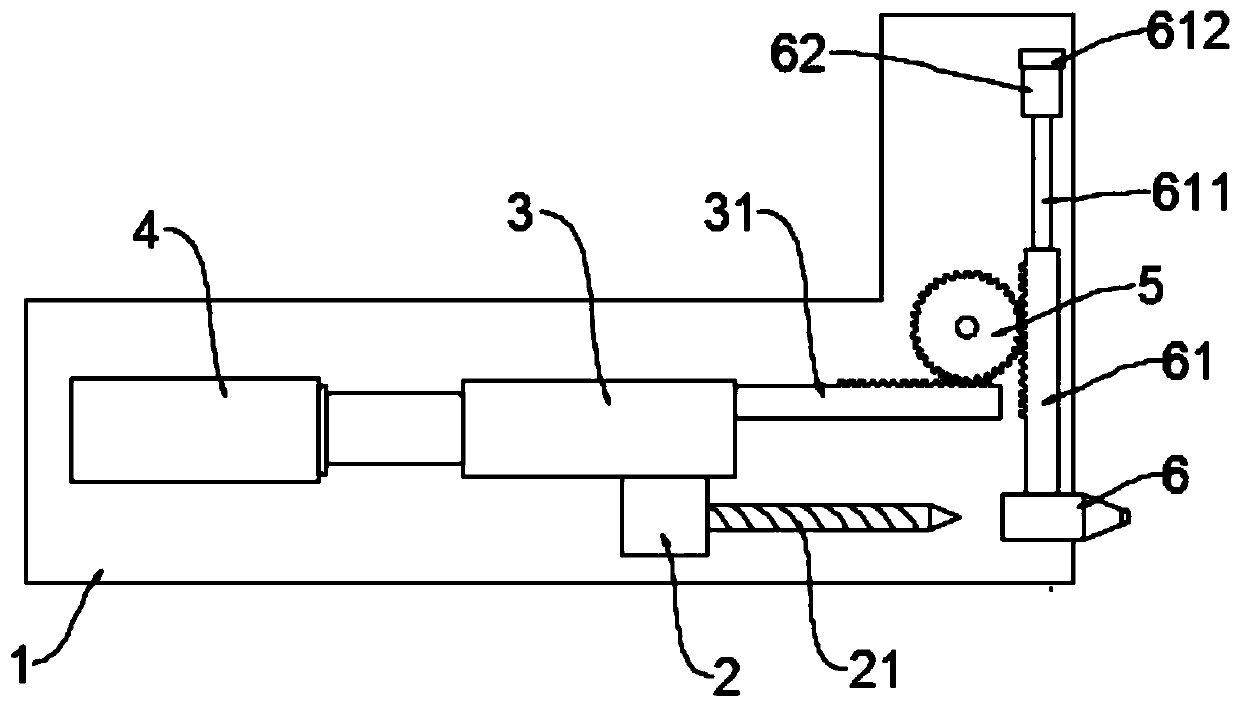

[0023] see Figure 1-2 , in an embodiment of the present invention, a drilling positioning mechanism includes a base 1 and a drilling motor 2; The mounting base 3 is slidably connected to the base 1 and can move along the length direction of the drill rod 21. The base 1 is equipped with a feeder 4 that drives the mounting base 3. When in use, the drilling motor 2 drives the drill rod 21 rotates, and then the feed device 4 drives the mounting seat 3 to move, thereby completing the feeding work to realize feeding.

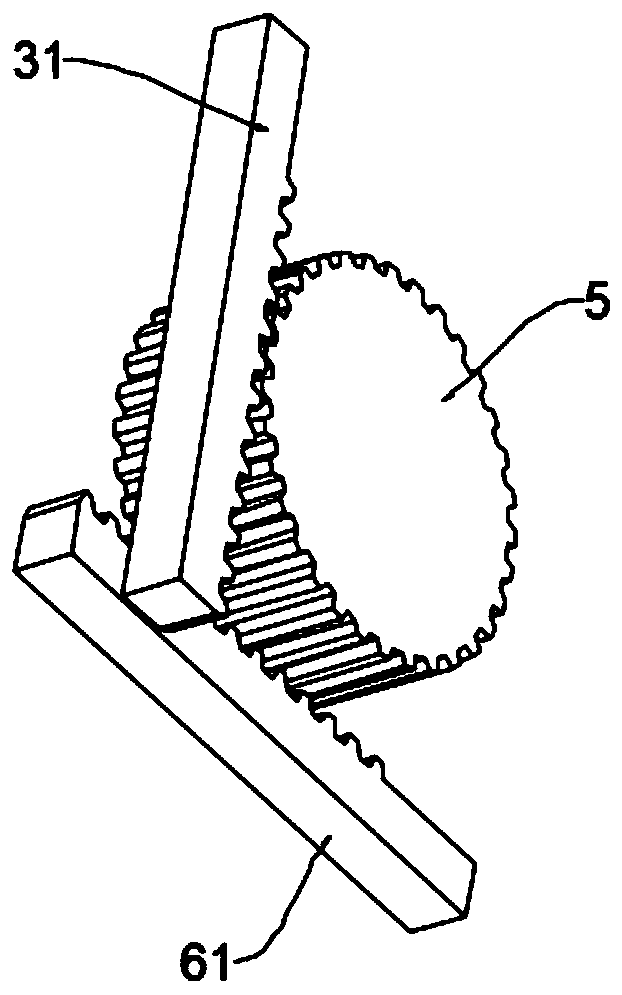

[0024] One end of the same side of the mounting seat 3 and the drill rod 21 is fixed with a first rack 31, and the base 1 is rotatably connected with a gear 5 meshing with the first rack 31; The side is provided with a second rack 61 meshing with it, the first rack 31 and the second rack 61 are out of position and vertical, the bottom of the second rack 61 is fixed with a laser emitter 6, and the laser generator 6 is slidably connected to the base 1 and can move al...

Embodiment 2

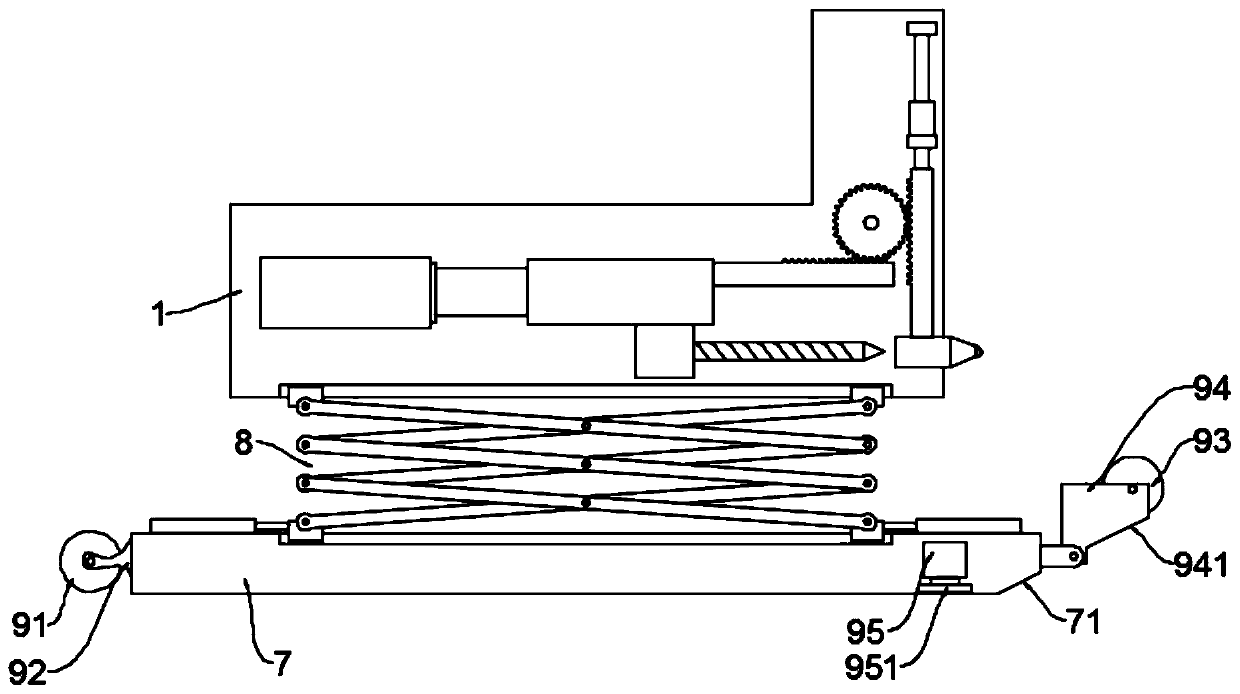

[0029] see Figure 3-4 , in an embodiment of the present invention, a drilling device includes the drilling positioning mechanism as described in Embodiment 1, and also includes a base 7; the base 7 is connected to the base 1 through a lifting mechanism 8, and can The height of the base can be adjusted to meet different construction needs. The base 7 is also equipped with a moving mechanism to facilitate the movement of the whole device and improve the flexibility of use.

[0030] The specific mechanism of the lifting mechanism 8 is not limited. Preferably, in this embodiment, the lifting mechanism 8 is a scissor lift.

[0031] Specifically, in this embodiment, the moving mechanism includes a rear support wheel 91 and a front support wheel 93, wherein the rear support wheel 91 is installed on the rear support frame 92 fixed on the base 7, and the front support wheel 93 is installed on the front support wheel 93. On the frame 94, the front support frame 94 is rotationally conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com