A pc wall panel mold with pre-embedded window frames and pre-embedded waterproof adhesive strips for prefabricated buildings

A waterproof adhesive strip and assembled technology, which is applied to molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of PC wallboard production, no pre-embedded waterproof adhesive strips, and large human factors, so as to save money. The effect of manual production, easy assembly and good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

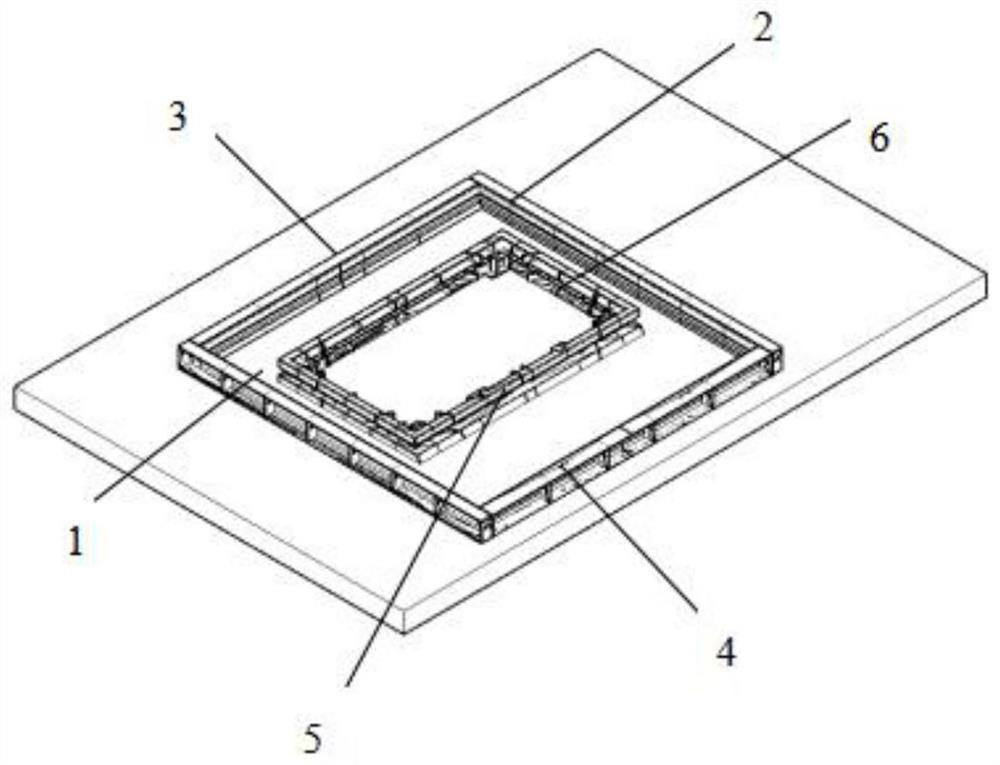

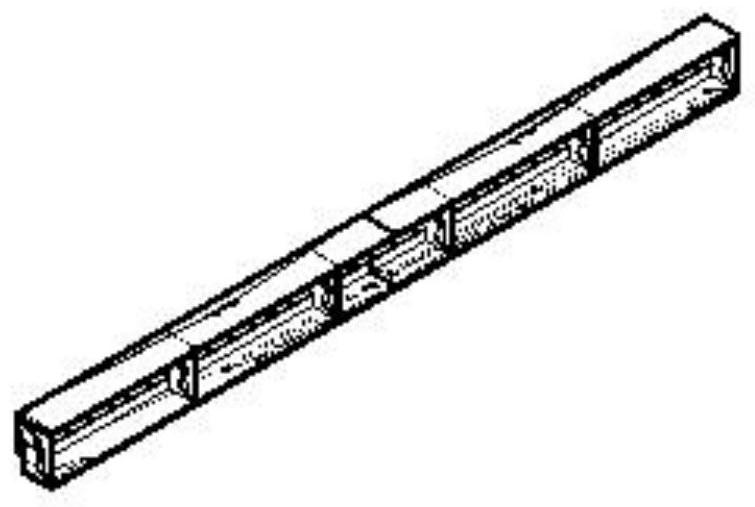

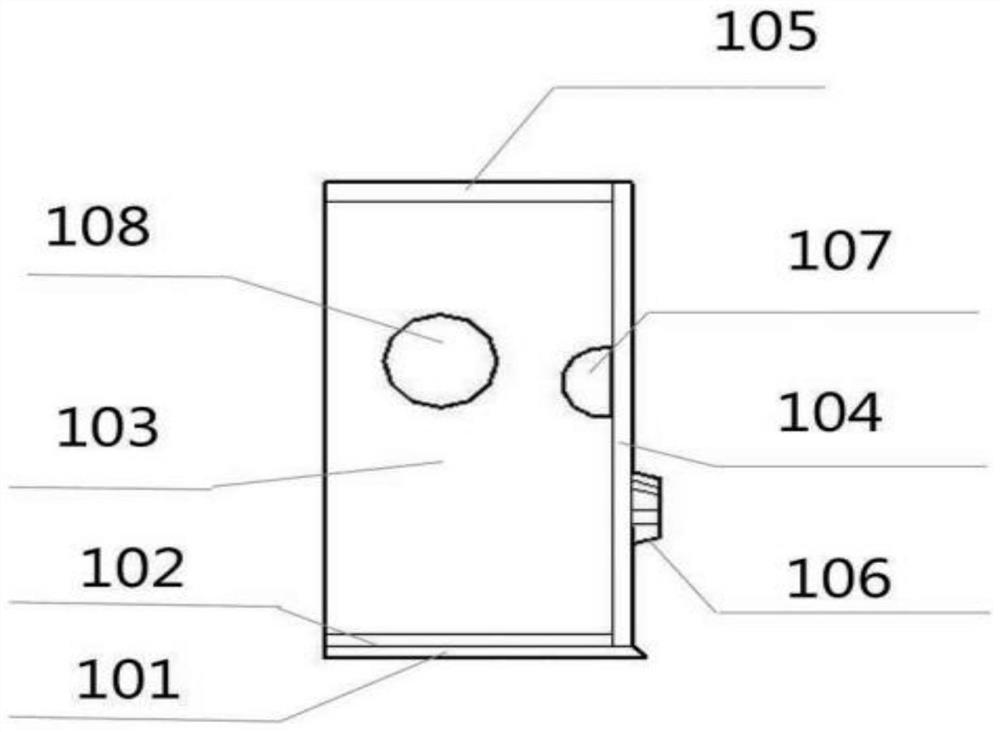

[0063] Such as Figure 1-Figure 43 As shown, the PC wall panel mold for prefabricated buildings with pre-embedded window frames and pre-embedded waterproof adhesive strips provided in this embodiment includes a mold table and belts that are connected end to end on the mold table to form a rectangular frame. The left end side formwork of the PC wall panel with pre-embedded waterproof adhesive strips and decompression space 1, the upper side formwork of the PC wall panel with pre-embedded waterproof adhesive strips and the water-proof shape of the outer low inner height structure 3, with pre-embedded waterproof adhesive strips and reducing The right side formwork 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com