Integrated collecting device for shredding flaky kelp

An all-in-one, kelp technology, which is applied in metal processing and other directions, can solve the problems of collecting hard-to-cut kelp and transporting kelp that cannot be cut, and achieves the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

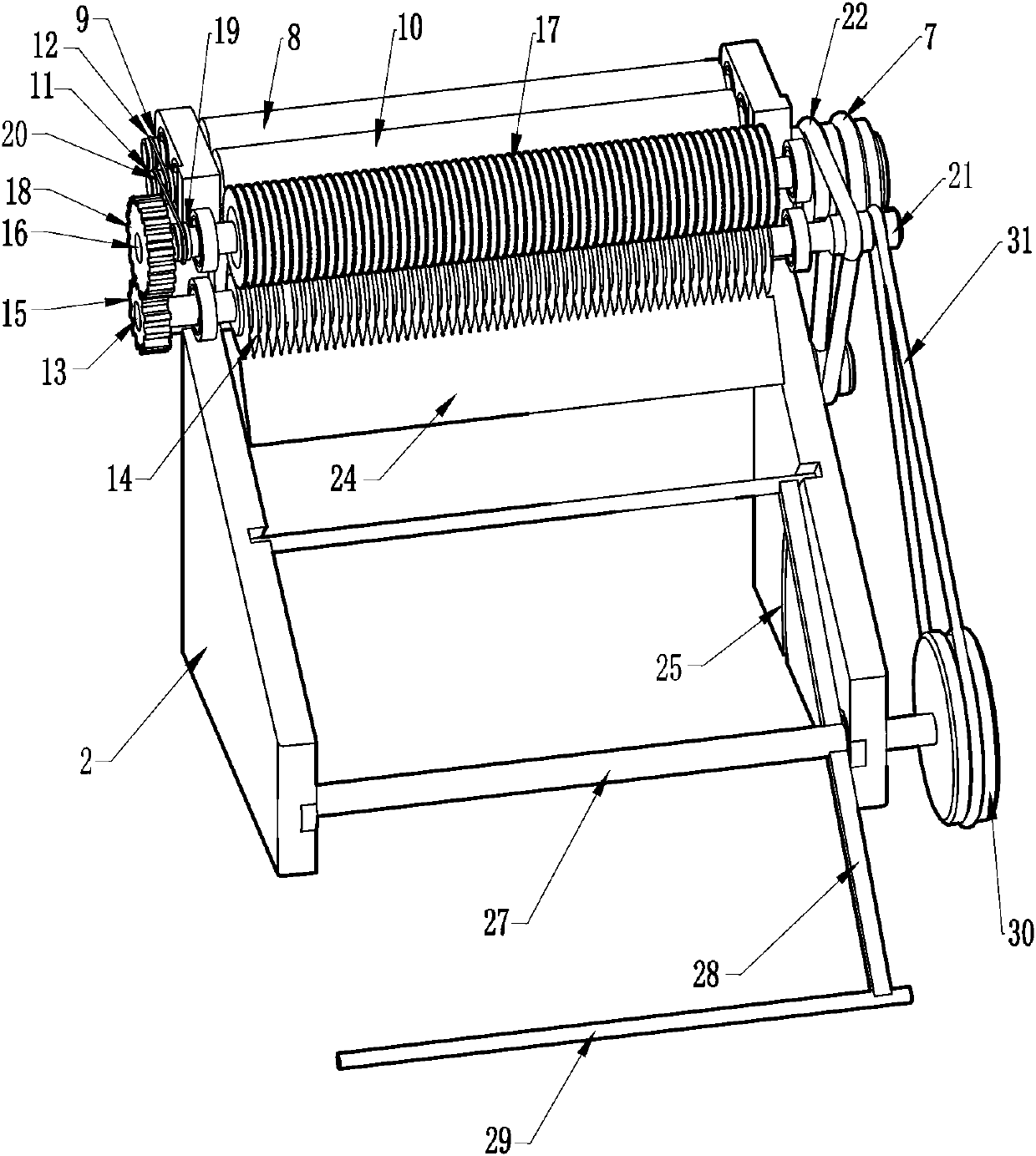

[0025] An integrated collection device for shredded kelp, such as Figure 1-6 As shown, it includes a base 1, a frame 2, a motor 3, a transmission device, a cutting device and a rotating device, the base 1 is fixedly connected with a frame 2, the frame 2 is equipped with a motor 3, and the frame 2 is provided with a transmission device, cutting device and rotating device, the cutting device cooperates with the conveying device, the rotating device cooperates with the conveying device, the conveying device is used for conveying the kelp, the cutting device is used for cutting the kelp, the rotating device is used for stirring the kelp, the frame 2. A cover 32 is provided at the left front end.

[0026] When the kelp needs to be shredded and collected, people start the motor 3 to rotate counterclockwise, and the motor 3 drives the transmission device, the cutting device and the rotating device to work, and then people put the kelp on the transmission device, and the transmission...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 3-5 Shown, also comprise the second drum 8, the first single-groove pulley 9, the 3rd drum 10, the second double-groove pulley 11 and the second belt 12, the left part rotation type in the frame 2 is provided with the second drum 8 and The third drum 10, the third drum 10 is located on the left side of the second drum 8, the second drum 8 is located above the first drum 4, the second drum 8 is equipped with a first single-groove pulley 9, and the third drum 10 is connected with The second double-groove pulley 11, the first single-groove pulley 9 and the second double-groove pulley 11 are all located outside the frame 2, the third belt 20 is wound on the second double-groove pulley 11, the second double-groove pulley 11 and the first A second belt 12 is wound between the single-groove pulleys 9 .

[0035] When the second runner 16 rotates clockwise, the second runner 16 drives the second single-groove pulley 19 to rotate clockw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com