Small-caliber plant sausage casing and preparation process thereof

A preparation process, small-caliber technology, applied in sausage casings, processed meat, food science, etc., can solve the problems of not considering performance, not realizing continuous production, etc., and achieve good skin-filling combination, excellent compressive strength, and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

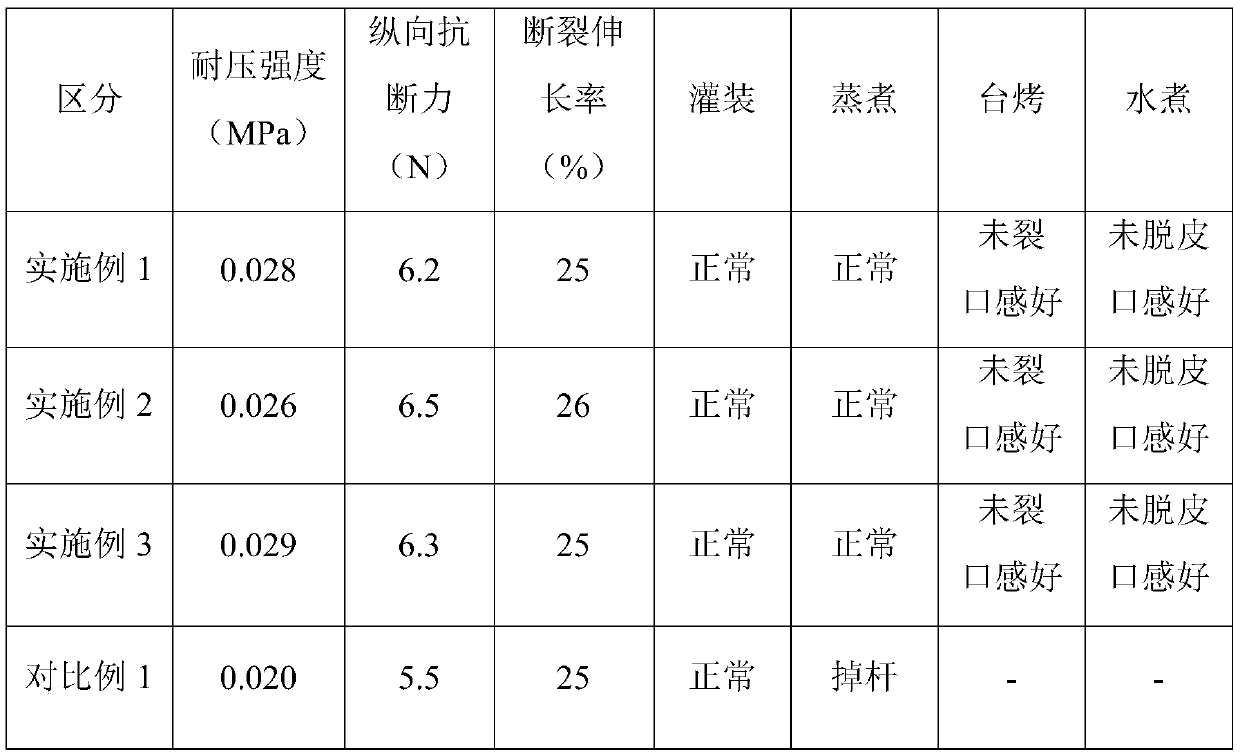

Examples

Embodiment 1

[0033] The glue used in the small-caliber vegetable casing includes the following raw materials in mass percentage: 1% sodium alginate, 0.2% microcrystalline cellulose, 0.05% sodium carboxymethyl cellulose, 0.1% starch, 0.1% glycerin , and the balance is water.

[0034] In the sodium alginate, the ratio of high G type and high M type sodium alginate is 1:3.

[0035] The preparation technology of described small-bore plant casing, comprises the following steps:

[0036] (1) Preparation of glue: mix water and glycerin evenly, and mix other powdery raw materials evenly; pour the liquid into the vacuum chopping machine and start it at low speed, then pour the solid powder into it, and continue chopping for 10 minutes until the mixture is uniform solution;

[0037] (2) Extrusion and coagulation: Pour the prepared glue into the extruder, extrude the casing through the machine head, and blow in air at the same time. The air pressure is set to 0.03MPa. After extrusion, the use mass ...

Embodiment 2

[0042] The glue used in the small-caliber vegetable casing includes the following raw materials in mass percentage: 10% sodium alginate, 2.0% microcrystalline cellulose, 0.5% sodium carboxymethyl cellulose, 2% starch, 1% glycerin , and the balance is water.

[0043] In the sodium alginate, the ratio of high G type and high M type sodium alginate is 1:4.

[0044] The preparation technology of described small-bore plant casing, comprises the following steps:

[0045] (1) Preparation of glue: mix water and glycerin evenly, and mix other powdery raw materials evenly; pour the liquid into the vacuum chopping machine and start it at a low speed, then pour the solid powder into it, and continue chopping for 30 minutes until the mixture is uniform solution;

[0046] (2) Extrusion and coagulation: Pour the prepared glue into the extruder, extrude the casing through the machine head, and blow in air at the same time, the air pressure is set to 0.03MPa, after extrusion molding, the use...

Embodiment 3

[0051] The glue used in the small-caliber vegetable casing includes the following raw materials in mass percentage: 6% sodium alginate, 1.5% microcrystalline cellulose, 0.3% sodium carboxymethyl cellulose, 1.3% starch, 0.6% glycerin , and the balance is water.

[0052] In the sodium alginate, the ratio of high G type and high M type sodium alginate is 1:5.

[0053] The preparation technology of described small-bore plant casing, comprises the following steps:

[0054] (1) Preparation of glue: mix water and glycerin evenly, and mix other powdery raw materials evenly; pour the liquid into the vacuum chopping machine and start it at a low speed, then pour the solid powder into it, and continue chopping for 20 minutes until the mixture is uniform solution;

[0055] (2) Extrusion and coagulation: Pour the prepared glue into the extruder, extrude the casing through the machine head, and blow in air at the same time. The air pressure is set to 0.03MPa. After extrusion, the use mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com