Anti-loosening method and device for pile hammer head

A technology for preventing loosening and piling hammer, which is applied in the direction of threaded fasteners, connecting components, screws, etc., which can solve the problems of low connection strength, easy loosening, and loose inner nut and connecting body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described in detail below.

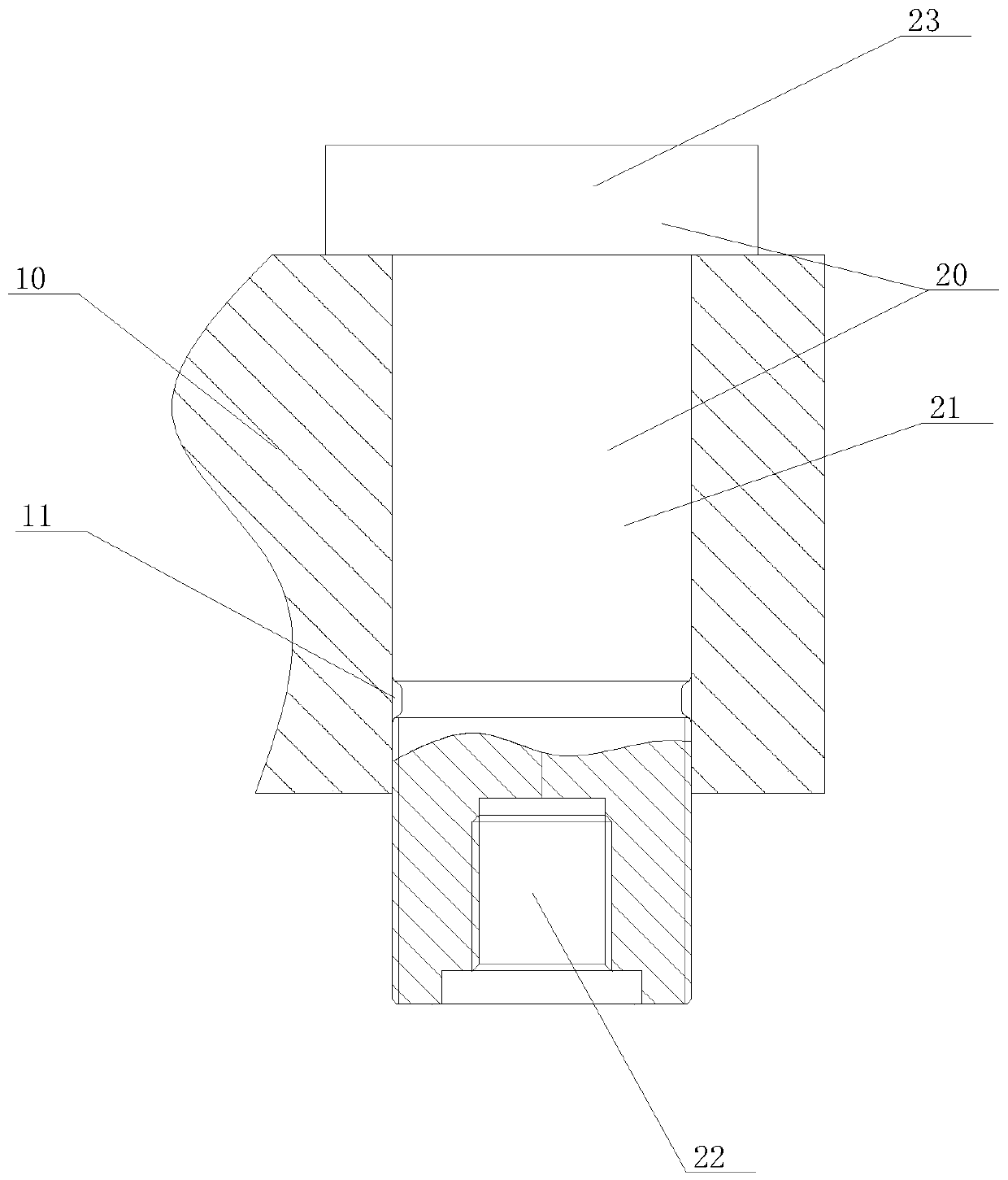

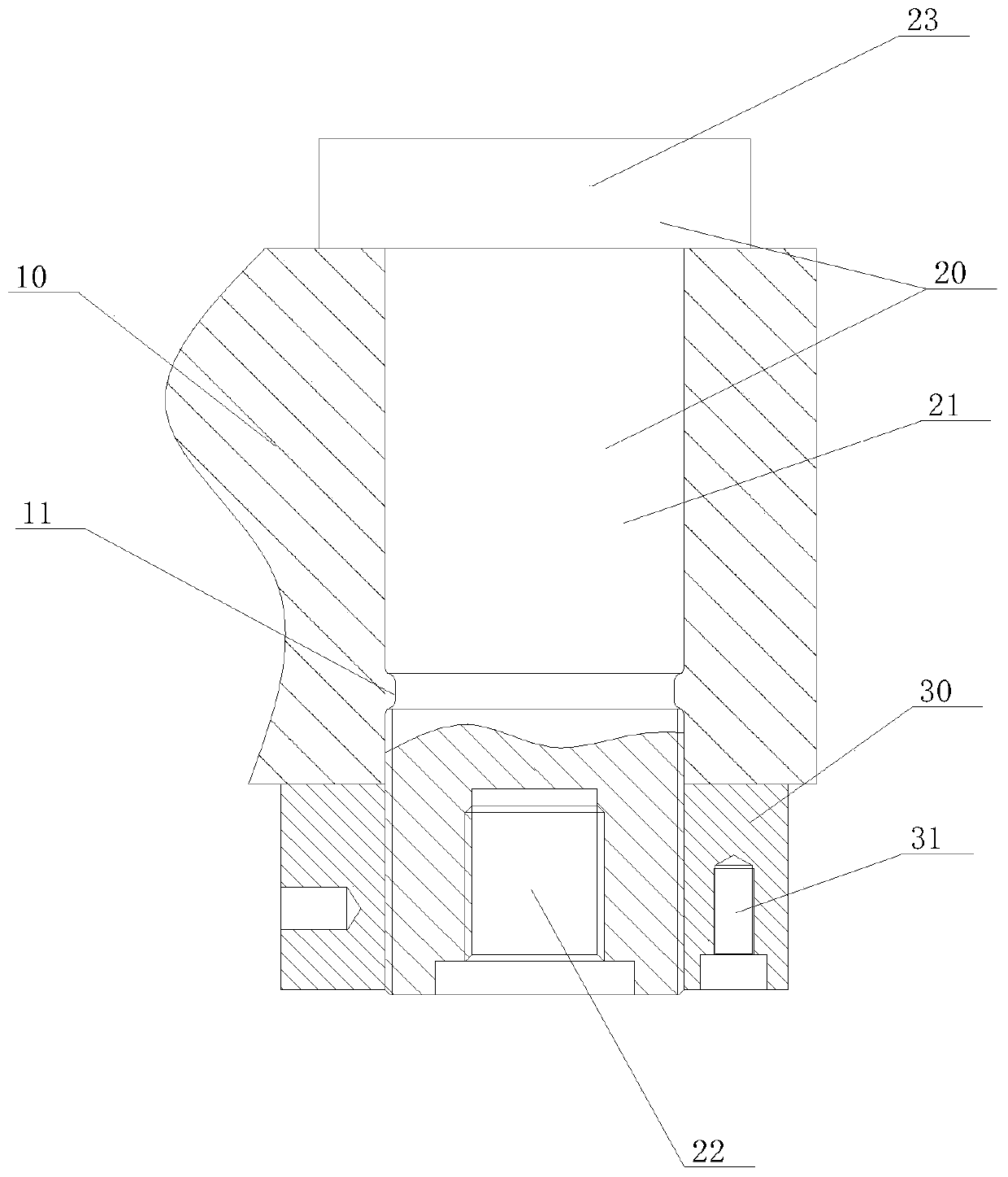

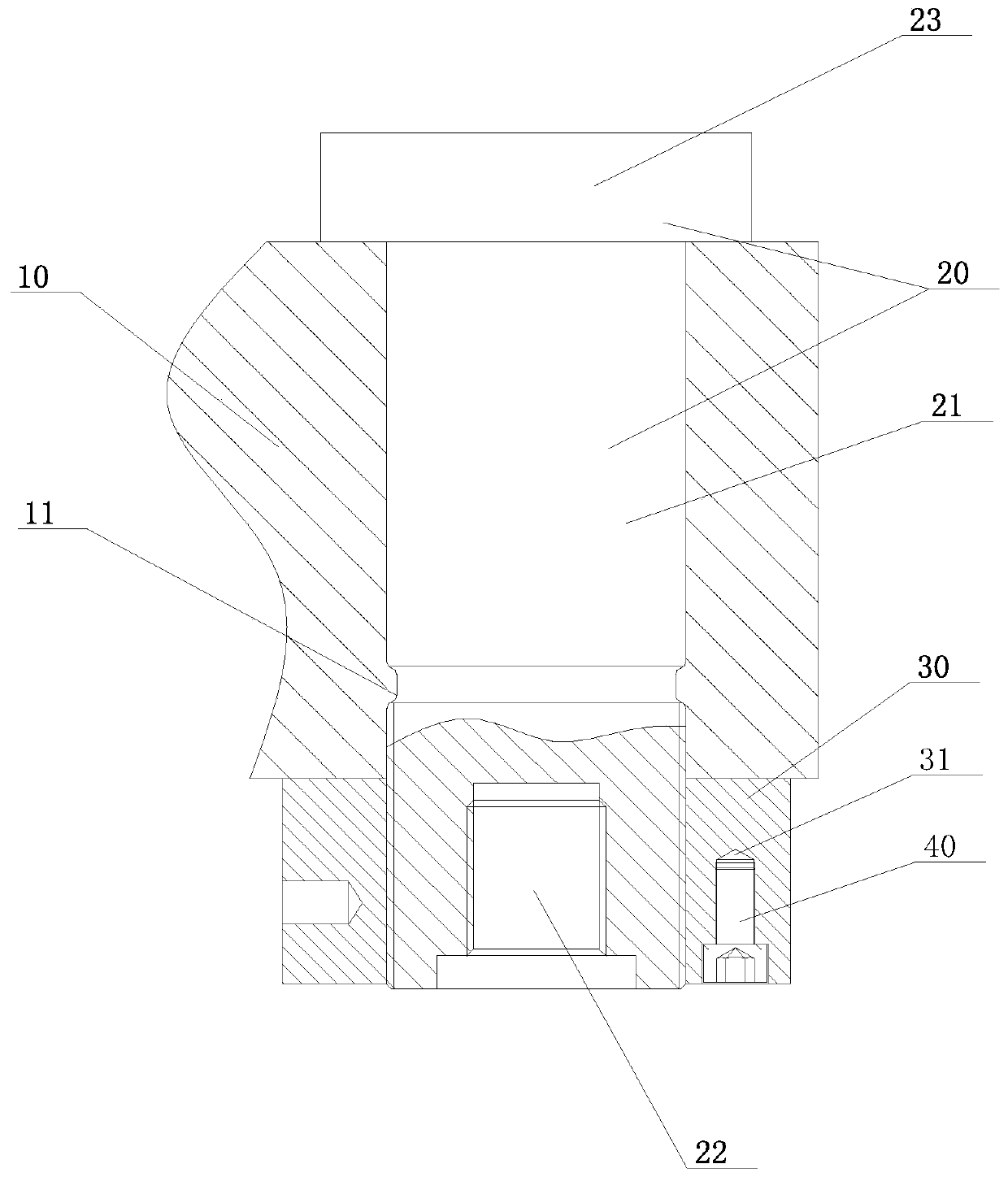

[0050] Such as Figure 1 to Figure 5 As shown, a kind of piling hammerhead anti-loosening method provided by the present invention comprises the following steps:

[0051] (1), such as figure 1 As shown, the pin shaft 20 of the anti-loosening device for the piling hammer is threaded through the shaft hole 11 of the assembly 10 and the nut 30 through the pin bolt 21; wherein, the anti-loosening device for the piling hammer includes the assembly 10, the pin 20. Nut 30, hexagon socket head cap screw 40, end flange 50, pin shaft 20 includes pin bolt 21, pin cover 23, the outer surface of pin bolt 21 has the first external thread, and the lower end surface of pin bolt 21 is provided with The first screw hole 22, the first screw hole 22 has a first internal thread, the thread direction of the first internal thread is opposite to that of the first external thread; the lower end surface of the nut 30 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com