Pre-hardening treatment method of high manganese steel

A technology of pre-hardening treatment and high manganese steel, which is applied in the field of high manganese steel manufacturing in the metallurgical industry, can solve the problems of poor pre-hardening effect of high manganese steel, achieve hardening effect, increase thickness, and reduce overall product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

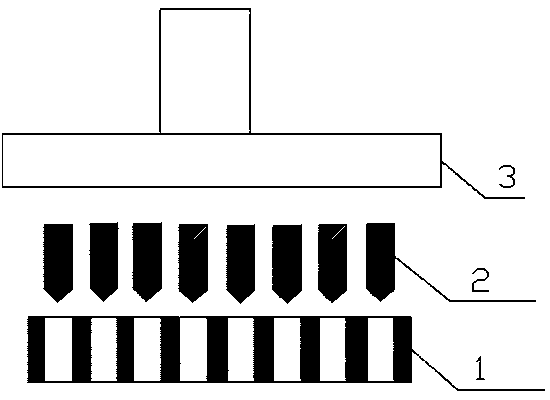

Image

Examples

Embodiment 1

[0023] This embodiment selects high manganese steel casting hole plate and high manganese steel plug nail made by Mn13, the diameter of the through hole of high manganese steel casting hole plate is 10mm, and the diameter of high manganese steel plug nail is 10.3mm. The pre-hardening treatment method includes the following steps: insert the cone end of the high manganese steel plug nail into the through hole of the high manganese steel cast orifice plate, and then put the assembled workpiece into a temperature-controlled furnace for heating, and the temperature is controlled at 200 ℃; after heating, use a heavy-duty impact machine with a pressure of 1,000 tons to smash the high-manganese steel plug nails with temperature into the through-holes of the high-manganese steel cast orifice plate; The temperature in the tank is controlled at -180°C, and after keeping for 3 hours, it is taken out to form a finished product.

Embodiment 2

[0025] This embodiment selects high manganese steel cast hole plate and high manganese steel plug nail made by Mn17, the diameter of the through hole of high manganese steel cast hole plate is 20mm, and the diameter of high manganese steel plug nail is 20.5mm. The pre-hardening treatment method includes the following steps: insert the cone end of the high manganese steel plug nail into the through hole of the high manganese steel cast orifice plate, and then put the assembled workpiece into a temperature-controlled furnace for heating, and the temperature is controlled at 230 ℃; After heating, use a heavy-duty impact machine with a pressure of 1200 tons to smash the high-manganese steel plug nails with temperature into the through-holes of the high-manganese steel cast orifice plate; The temperature in the tank was controlled at -190°C, and after keeping for 2.5 hours, it was taken out to form a finished product.

Embodiment 3

[0027] This embodiment selects high manganese steel casting hole plate and high manganese steel plug nail made by Mn20, the diameter of the through hole of high manganese steel casting hole plate is 30mm, the diameter of high manganese steel plug nail is 30.8mm, the high manganese steel The pre-hardening treatment method includes the following steps: insert the cone end of the high manganese steel plug nail into the through hole of the high manganese steel cast orifice plate, and then put the assembled workpiece into a temperature-controlled furnace for heating, and the temperature is controlled at 260 ℃; after heating, use a heavy-duty impact machine with a pressure of 1400 tons to smash the high-manganese steel plug nails with temperature into the through-holes of the high-manganese steel cast orifice plate; The temperature in the tank is controlled at -200°C, and after keeping for 2 hours, it is taken out to form a finished product.

[0028] The properties of the high manga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com