An obtuse angle elbow clamping device

A technology of clamping device and pipe bending, applied in workpiece clamping device, positioning device, clamping and other directions, can solve the problems of inability to clamp pipes with different angles and sizes, and inability to freely turn over and rotate. One-time processing, improved practicability, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

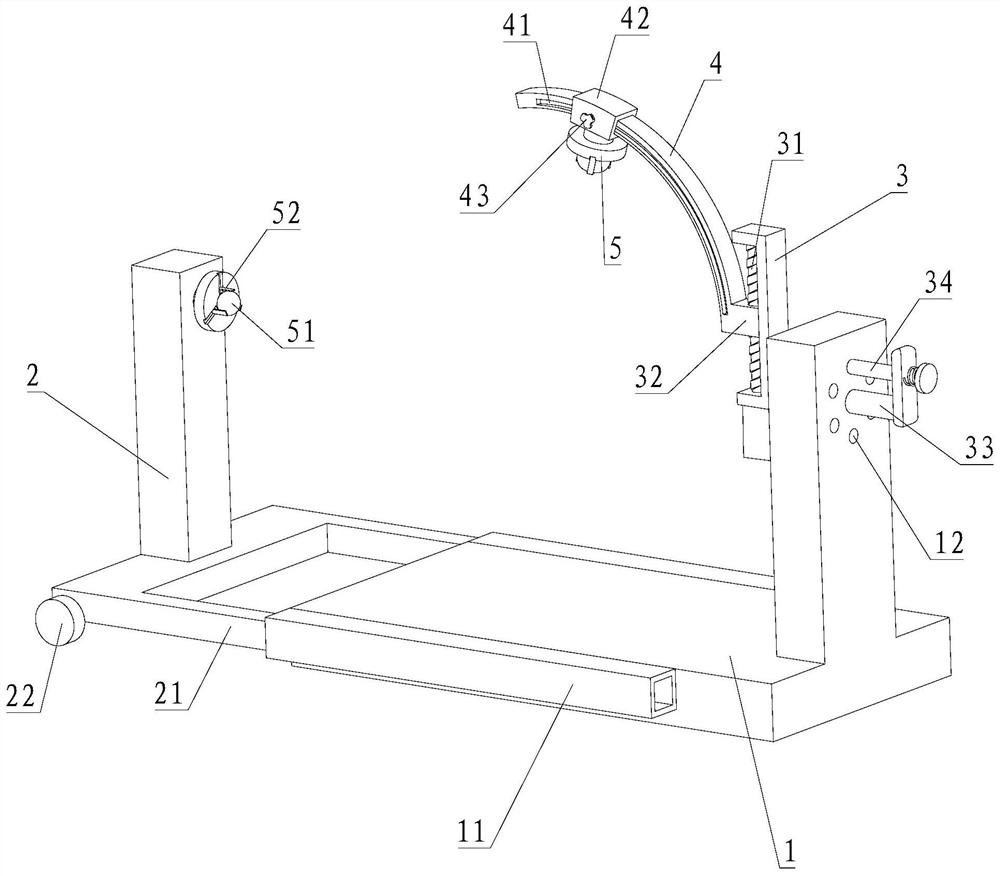

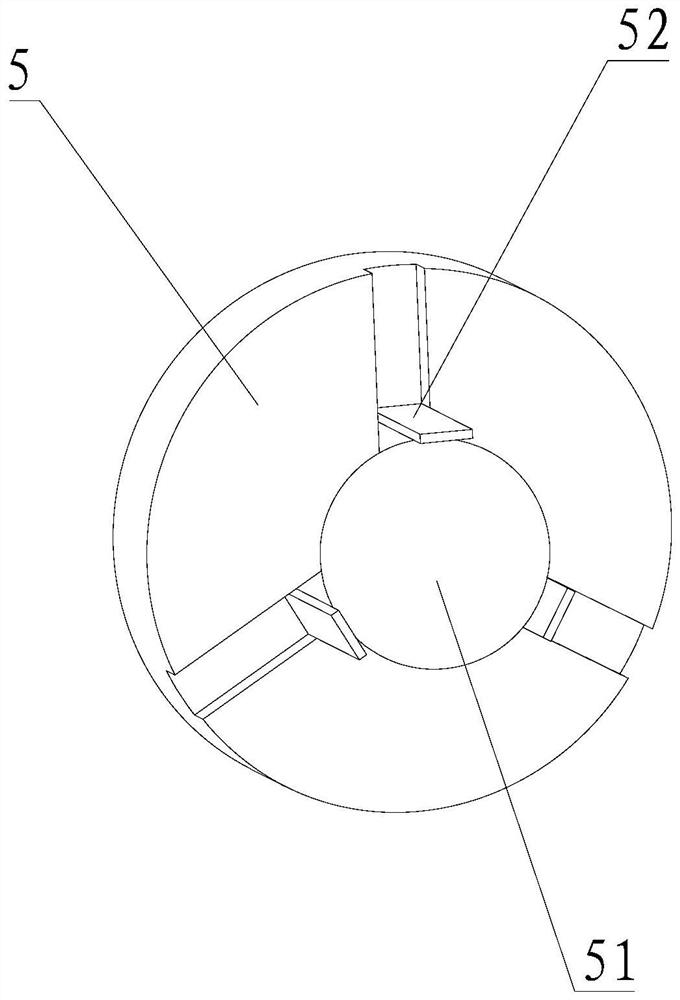

[0045] A clamping device for obtuse angled pipes, comprising a frame 1, a length adjustment part 2, a height adjustment part 3, an angle adjustment part 4 and two clamping parts 5;

[0046] The length adjustment part 2 is slidingly connected with the frame 1, and the length adjustment part 2 is used to adjust the distance between the two clamping parts 5; the bottom of the frame 1 is fixedly connected with a hollow pipe 11, and the length adjustment A slide bar 21 is provided at the bottom of the part 2, and the slide bar 21 is slidably connected in the hollow tube 11, and the end of the slide bar 21 away from the frame 1 is fixedly connected with a roller 22;

[0047] The height adjustment part 3 is rotationally connected with the frame 1, and the height adjustment part 3 is used to adjust the radius of rotation of the clamping part 5 connected to the angle adjustment part 4; the height adjustment part 3 is rod-shaped, and the The bottom end of the height adjustment part 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com