Fully-automatic spinning emulsified oil supply system

A technology for supplying system and emulsified oil, which is applied in filament/thread forming, textile and papermaking, chemical instruments and methods, etc., can solve the problems of high labor intensity, easy transportation errors, and high inlet water temperature, saving labor costs, Guaranteed accuracy, improved accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

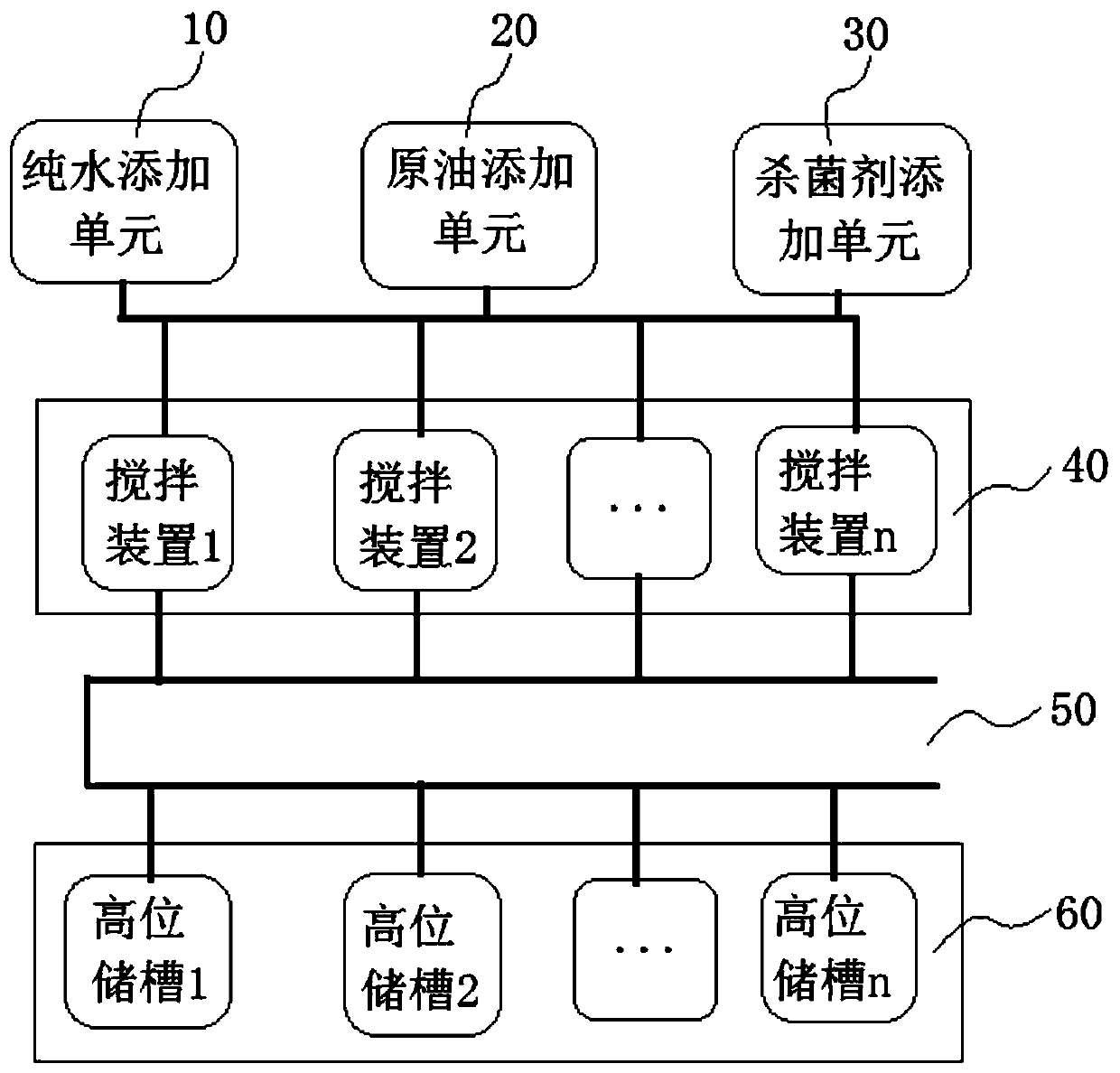

[0050] Embodiments of the present invention provide a fully automatic spinning emulsified oil supply system, such as figure 1 As shown, it includes at least a raw material addition system, a stirring system, a conveying system and a control system.

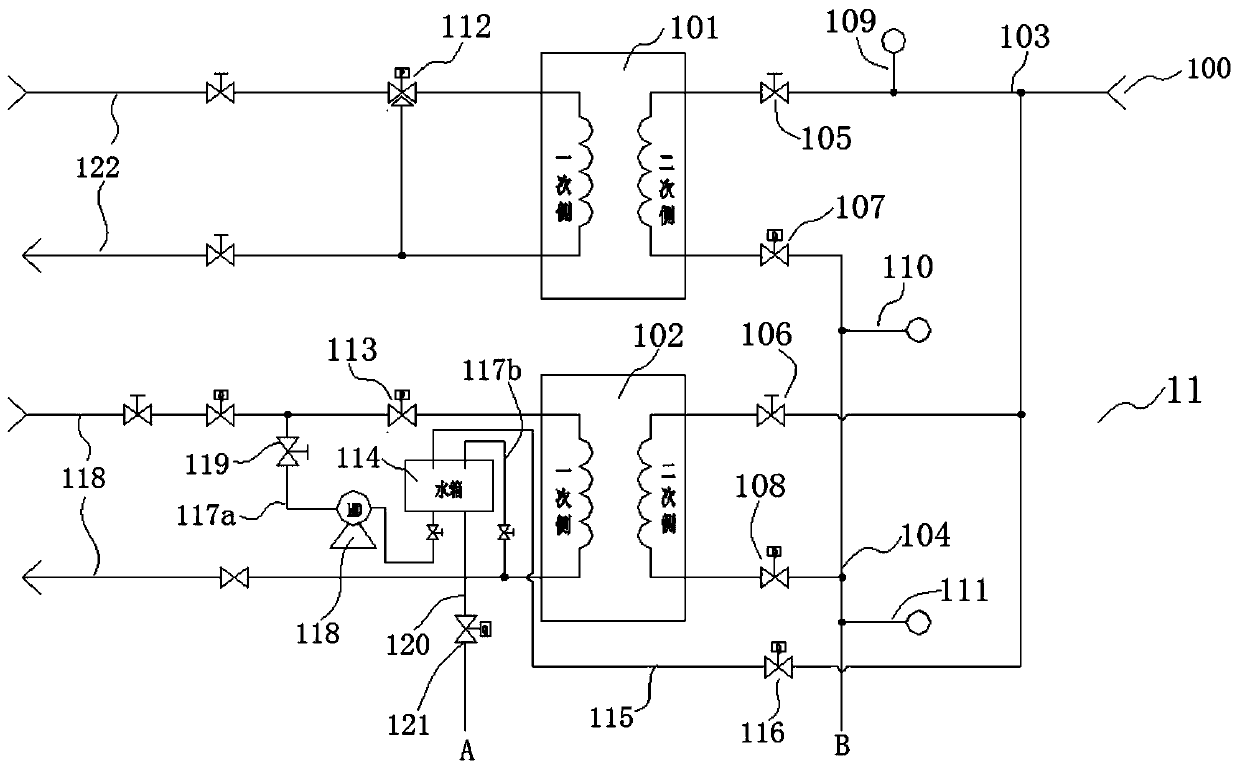

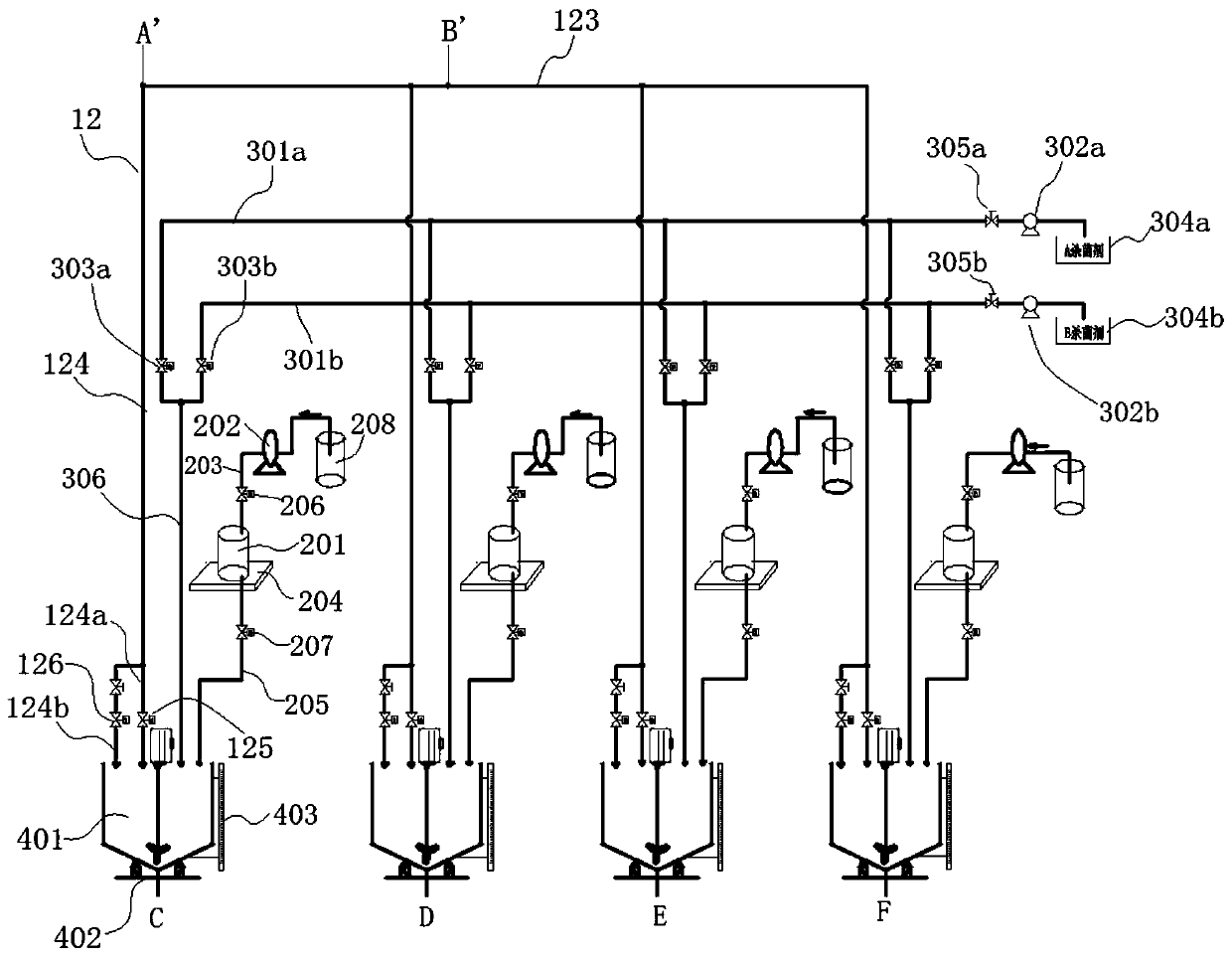

[0051] Wherein, the raw material addition system includes a pure water addition unit 10 for adding pure water to the stirring system, a crude oil addition unit 20 for quantitatively adding crude oil to the stirring system, and a bactericide adding unit 30 for quantitatively adding bactericide to the stirring system . The stirring system 40 includes at least one stirring device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com