Diesel engine exhaust particulate matter sampling and sealing system and method

A diesel engine and particulate matter technology, which is applied in the field of diesel engine exhaust particulate matter sampling and storage systems, can solve the problems of difficulty in accurately extracting exhaust particulate matter samples, inconvenient portability, complex structure, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

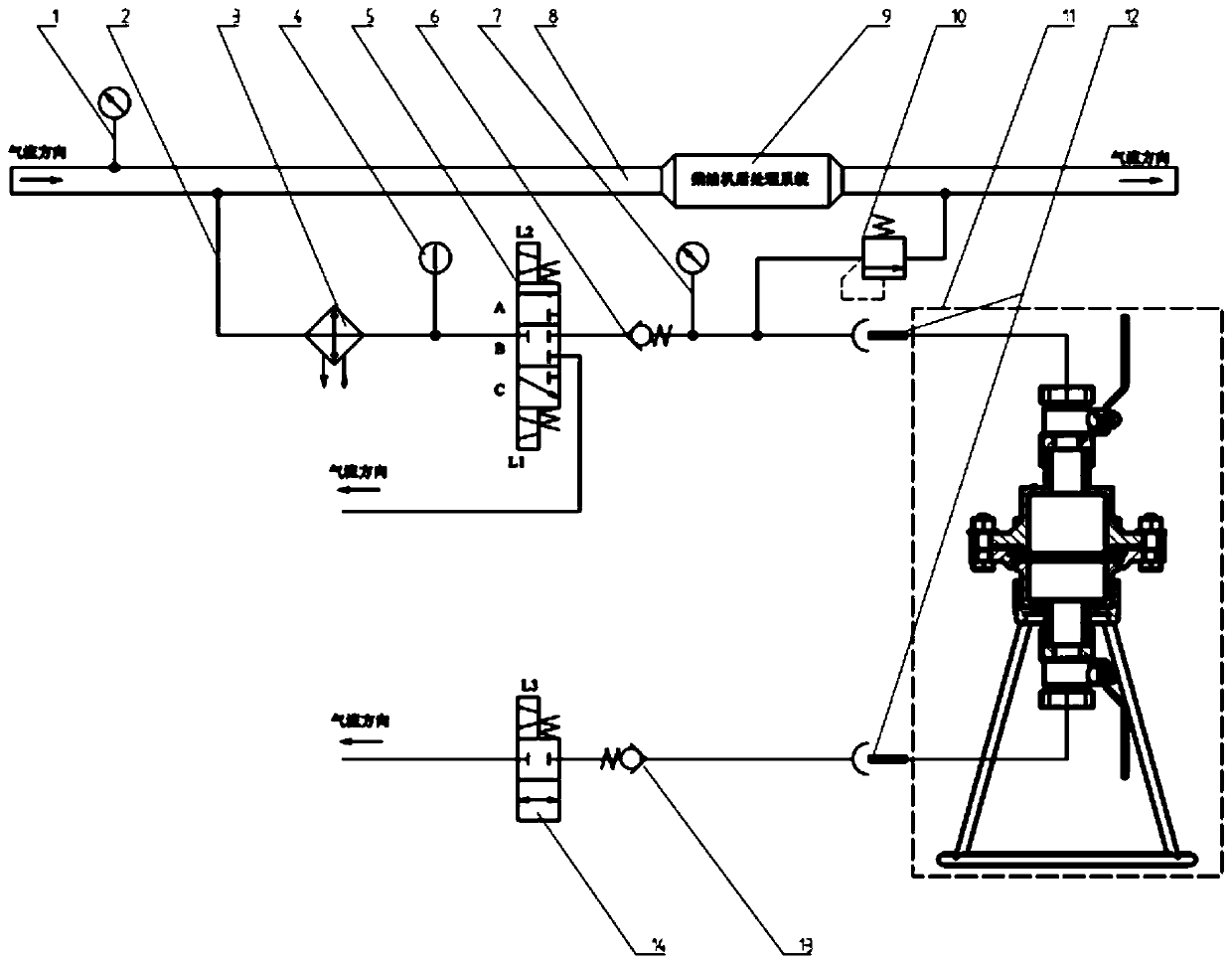

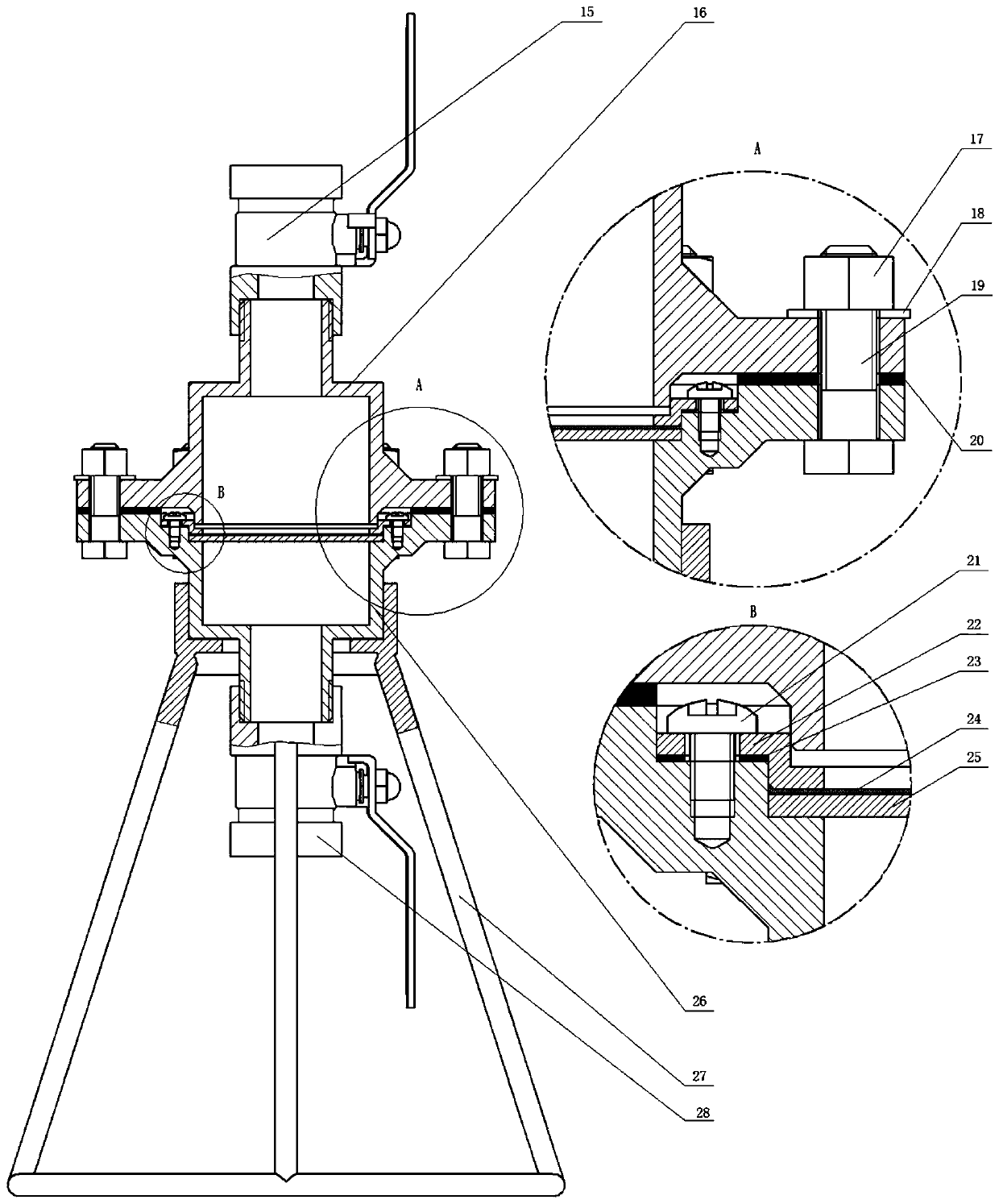

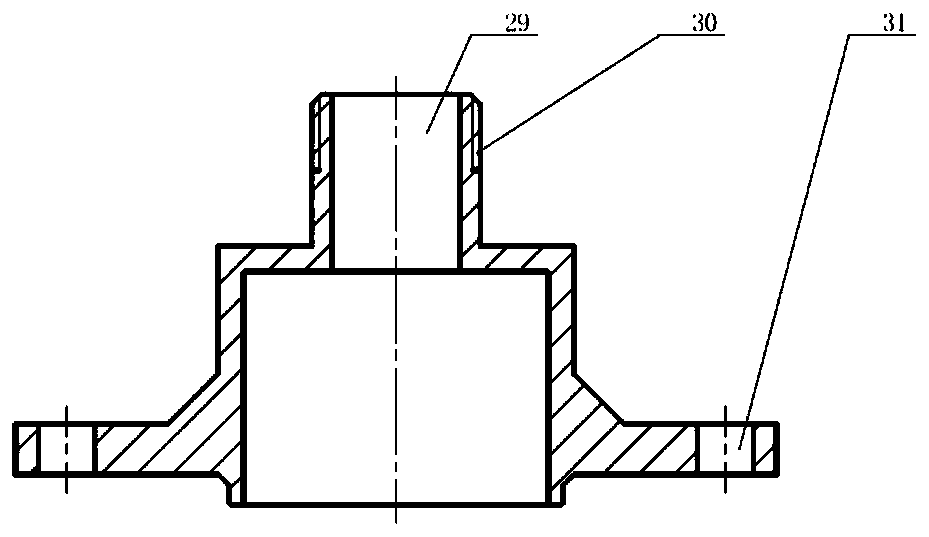

[0030] Embodiment 1: as Figure 1-8 As shown, a diesel engine exhaust particulate matter sampling and storage system, a diesel engine exhaust particulate matter sampling and storage system, includes a sampling pipeline 2, a cooler 3, a two-electric three-position three-way solenoid valve 5, a one-way valve I6, a one-way Valve II 13, overflow valve 10, union 12, two-position two-way solenoid valve 14, sampling tank module 11 and control circuit;

[0031] The entrance of the sampling pipeline 2 is located at the front end of the diesel engine post-processing system 9 on the diesel engine exhaust pipe 8; part of the gas enters the sampling pipeline 2 by itself by using the exhaust back pressure, and the diesel engine post-processing system 9 is located at the diesel engine exhaust pipe 8 The middle part is to increase the exhaust back pressure; the overflow valve 10 is connected to the rear end of the diesel engine post-processing system 9; after the pressure sensor II7 access po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com