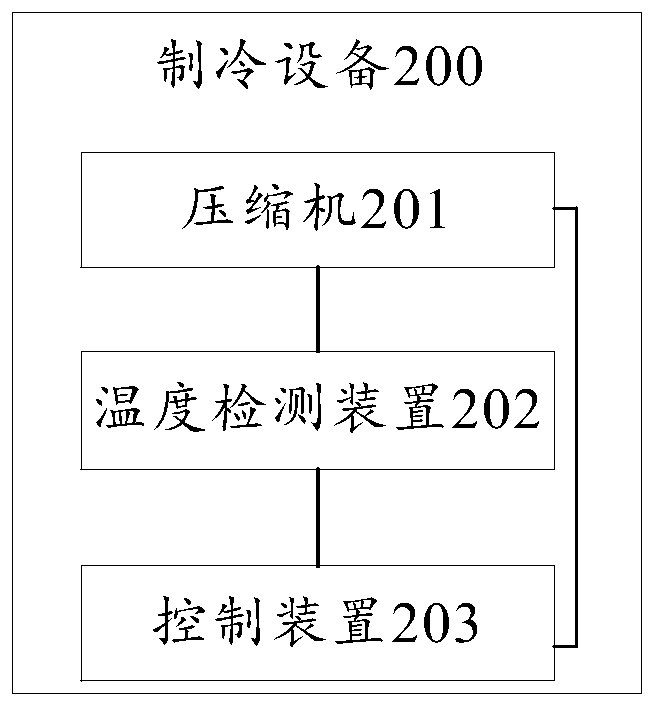

Refrigeration equipment and shutdown control method of compressor of refrigeration equipment

A technology of refrigeration equipment and control method, which is applied in the field of compressor control, can solve problems such as movement bias, large jitter, noise, etc., and achieve the effect of avoiding noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

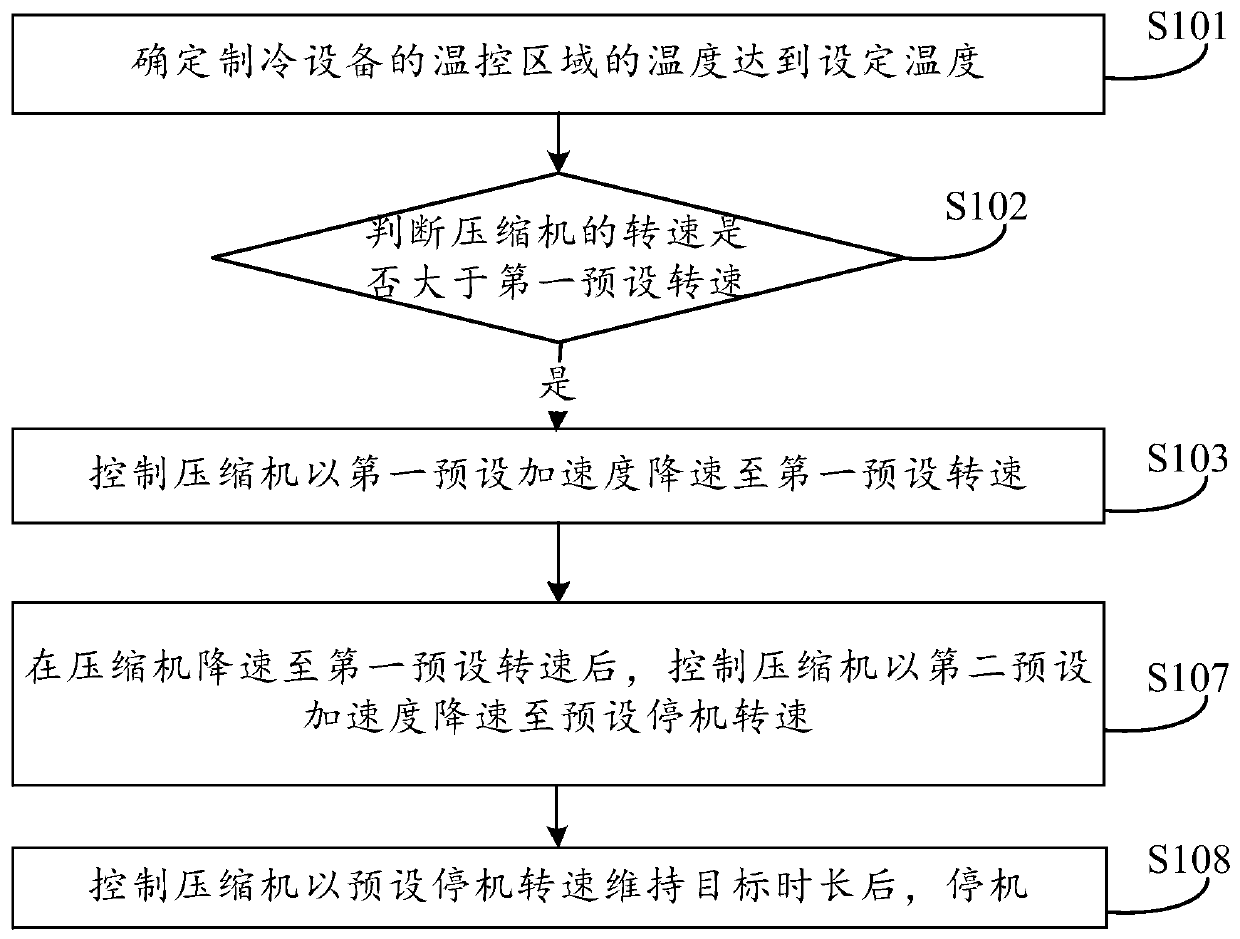

[0070] Example 1: The target speed of a certain series of compressors is 4100R, the starting speed of the compressor (oiling speed) is 2400R, and the minimum speed of this series of compressors is 1200R. Two stopping methods are used for stopping tests. The two stopping methods are respectively. It is: Plan one, reduce to 2400R with a large acceleration and then reduce to the preset shutdown speed with a smaller acceleration and then maintain for 3 seconds; Plan two, directly reduce to the preset shutdown speed and maintain for 3 seconds.

[0071] Before using the above-mentioned scheme 1 and scheme 2 for the shutdown test, the preset shutdown speed and the second preset acceleration can be determined through the shutdown test. The specific determination method is shown in the following scheme 3:

[0072] Scheme 3. It is preliminarily determined that the preset shutdown speed is the minimum compressor speed of 1200R, and the first preset acceleration is 180R / S, which is 3r / s. 2 (Acc...

Embodiment 2

[0085] Embodiment 2: The target speed of a certain series of compressors is 4100R, the starting speed of the compressor (oiling speed) is 2400R, and the minimum speed of this series of compressors is 1200R. The compressor shutdown control method provided by this application is also implemented In Example 1, the program provided in the first scenario is used for 30 sets of shutdown tests, and the test results are as follows:

[0086] Table 1

[0087] Number of groups 123456 Stop vibration value (m / s 2 )

0.160.170.160.170.220.20 Number of groups 789101112 Stop vibration value (m / s 2 )

0.150.180.170.190.170.16 Number of groups 131415161718 Stop vibration value (m / s 2 )

0.170.150.150.180.140.21 Number of groups 192021222324 Stop vibration value (m / s 2 )

0.170.150.160.150.180.18 Number of groups 252627282930 Stop vibration value (m / s 2 )

0.180.160.170.160.160.18

[0088] It can be seen from the data in the table that if the compressor shutdown control method provided by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com