Method for preparing patterned single crystal thin film, patterned single crystal thin film and resonator

A single crystal thin film and patterning technology, applied in the field of patterned single crystal thin film preparation, patterned single crystal thin film and resonators, can solve the problems of difficult control of bonding pressure, large stress accumulation and high requirements for preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

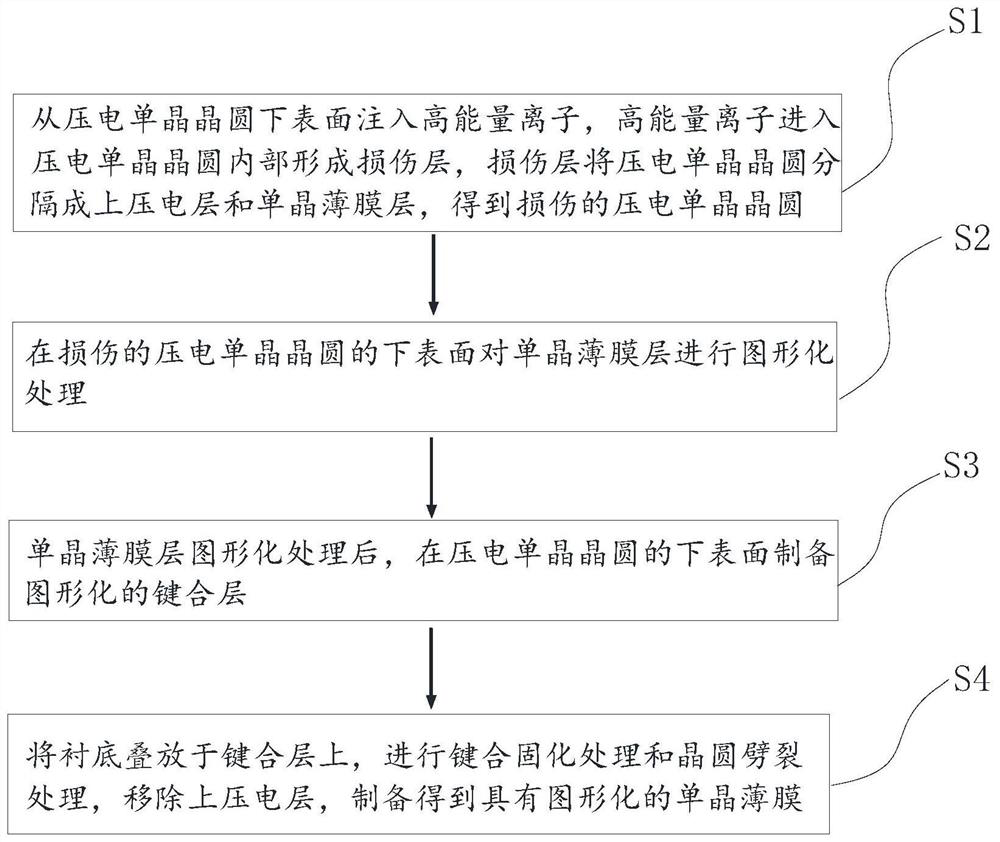

[0038] A method for preparing a patterned single crystal thin film, comprising the steps of:

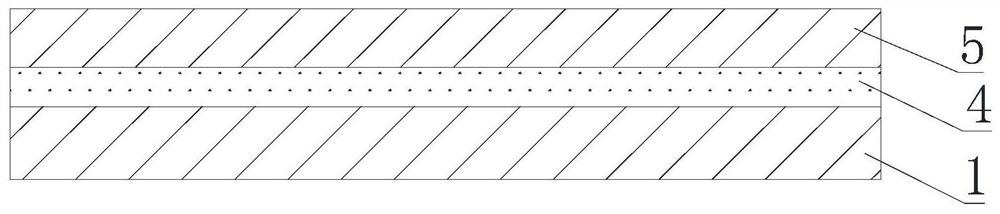

[0039] S1) High-energy ions A are injected from the lower surface of the piezoelectric single-crystal wafer, and the high-energy ions A enter the interior of the piezoelectric single-crystal wafer to form a damaged layer 4, and the damaged layer 4 separates the piezoelectric single-crystal wafer into an upper piezoelectric layer 5 and single crystal thin film layer 1 to obtain a damaged piezoelectric single crystal wafer;

[0040] S2) patterning the single crystal thin film layer 1 on the lower surface of the damaged piezoelectric single crystal wafer;

[0041] S3) After patterning the single crystal thin film layer 1, prepare a patterned bonding layer 2 on the lower surface of the piezoelectric single crystal wafer;

[0042] S4) Lay the substrate 3 on the bonding layer, perform bonding curing treatment and wafer splitting treatment, remove the upper piezoelectric layer, and prepare...

Embodiment 1

[0058] This embodiment proposes a preparation process of a patterned lithium niobate single crystal thin film, specifically:

[0059] 1) A lithium niobate piezoelectric single crystal wafer is selected, and positive monovalent helium ions (He + ), the implantation depth is 0.3 μm; a damaged layer is formed inside the lithium niobate piezoelectric single crystal wafer, and the damaged layer divides the lithium niobate piezoelectric single crystal wafer into an upper lithium niobate piezoelectric layer and a lithium niobate single crystal wafer. crystal thin film layer;

[0060] 2) Coating photoresist on the lower surface of the damaged lithium niobate piezoelectric single crystal wafer, exposing the photoresist with a patterned mask plate, and developing with a developing solution to obtain a patterned photoresist mask film, performing ion beam sputtering etching on the lithium niobate single crystal thin film layer with a patterned photoresist mask, the etching depth is great...

Embodiment 2

[0067] This embodiment proposes a preparation process of a patterned lithium tantalate single crystal thin film, specifically:

[0068] 1) A lithium tantalate piezoelectric single crystal wafer is selected, and positive monovalent hydrogen ions (H + ), the implantation depth is 2 μm; a damage layer is formed inside the lithium tantalate piezoelectric single crystal wafer, and the damage layer divides the lithium tantalate piezoelectric single crystal wafer into an upper lithium tantalate piezoelectric layer and a lithium tantalate single crystal film layer;

[0069] 2) Coating photoresist on the lower surface of the damaged lithium tantalate piezoelectric single crystal wafer, exposing the photoresist with a patterned mask plate, developing with a developer, and obtaining a patterned photoresist mask Reactive ion etching (RIE) is carried out to the lithium tantalate single crystal film layer with a patterned photoresist mask, the depth of etching is greater than the thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com