Glass fiber reinforced plastic stern shaft sleeve and bearing connecting joint

A technology of bearing connection and fiberglass, which is applied in ship propulsion, ship parts, ship construction, etc., can solve problems such as incomplete filling, affecting the connection strength between the bearing and the tail shaft, and deformation of the foam structure, so as to achieve high connection strength, The effect of simple structure and increased connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

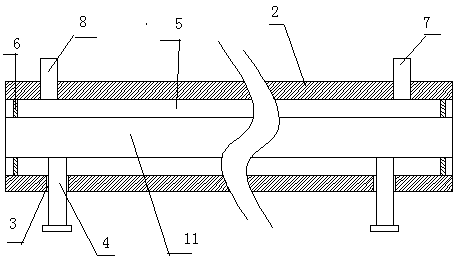

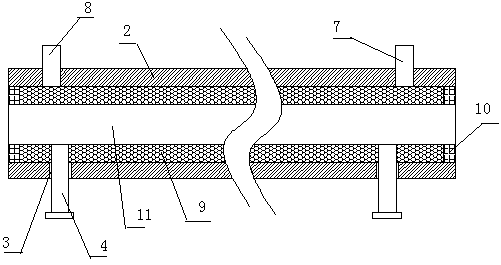

[0014] Below in conjunction with accompanying drawing, the present invention is further described:

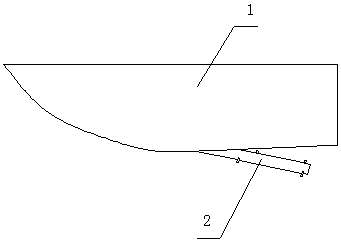

[0015] As shown in the drawings, a fiberglass stern bushing and bearing connection node is provided with a hull 1, and the lower end of the hull 1 is provided with a strip-shaped stern bushing 2, which is characterized in that the tail bushing 2 The front and rear ends of the bottom are respectively provided with bearing positioning groups. The bearing positioning group is composed of two positioning screw sleeves 3 and positioning bolts 4. The positioning screw sleeves 3 are pre-embedded in the tail shaft sleeve 2. The two positioning screw sleeves The screw sleeves 3 are symmetrically arranged on the left and right sides below the tail shaft sleeve 2. The axes of the two positioning screw sleeves 3 are 120°. The positioning screw sleeves 3 are provided with positioning bolts 4, and the positioning bolts 4 penetrate into the tail shaft sleeve 2. The bearing 11 is supported and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com