Manufacturing method for layered magnetic luster diffusion effect

A production method and layered technology, applied in the post-processing of printing, printing, printing devices, etc., can solve the problem of text, pattern and photo decoration, poor beautification effect, insufficient utilization of magnetic ink pigments, anti-counterfeiting performance needs to be improved, etc. Problems, to achieve the effect of improving efficiency and not difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for producing a layered magnetic brilliance diffusion effect, comprising the following steps:

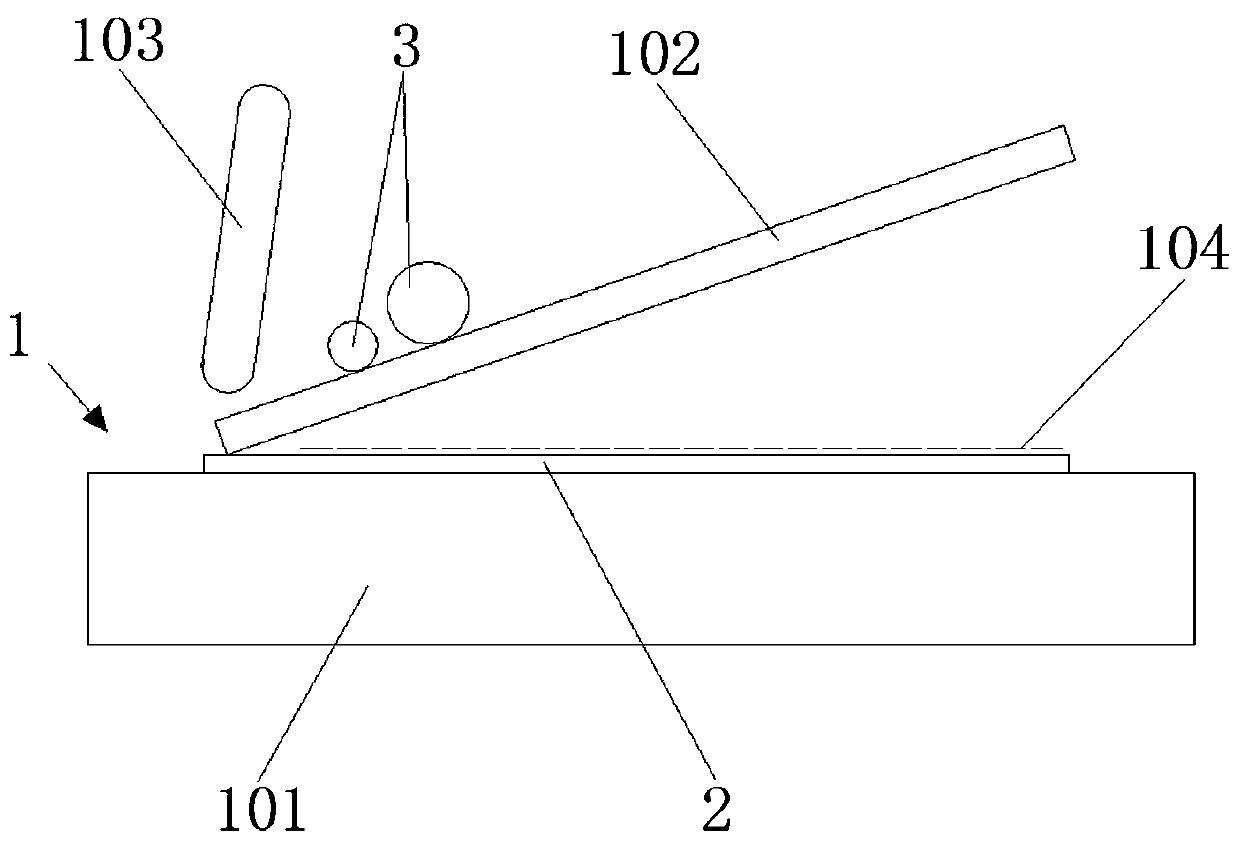

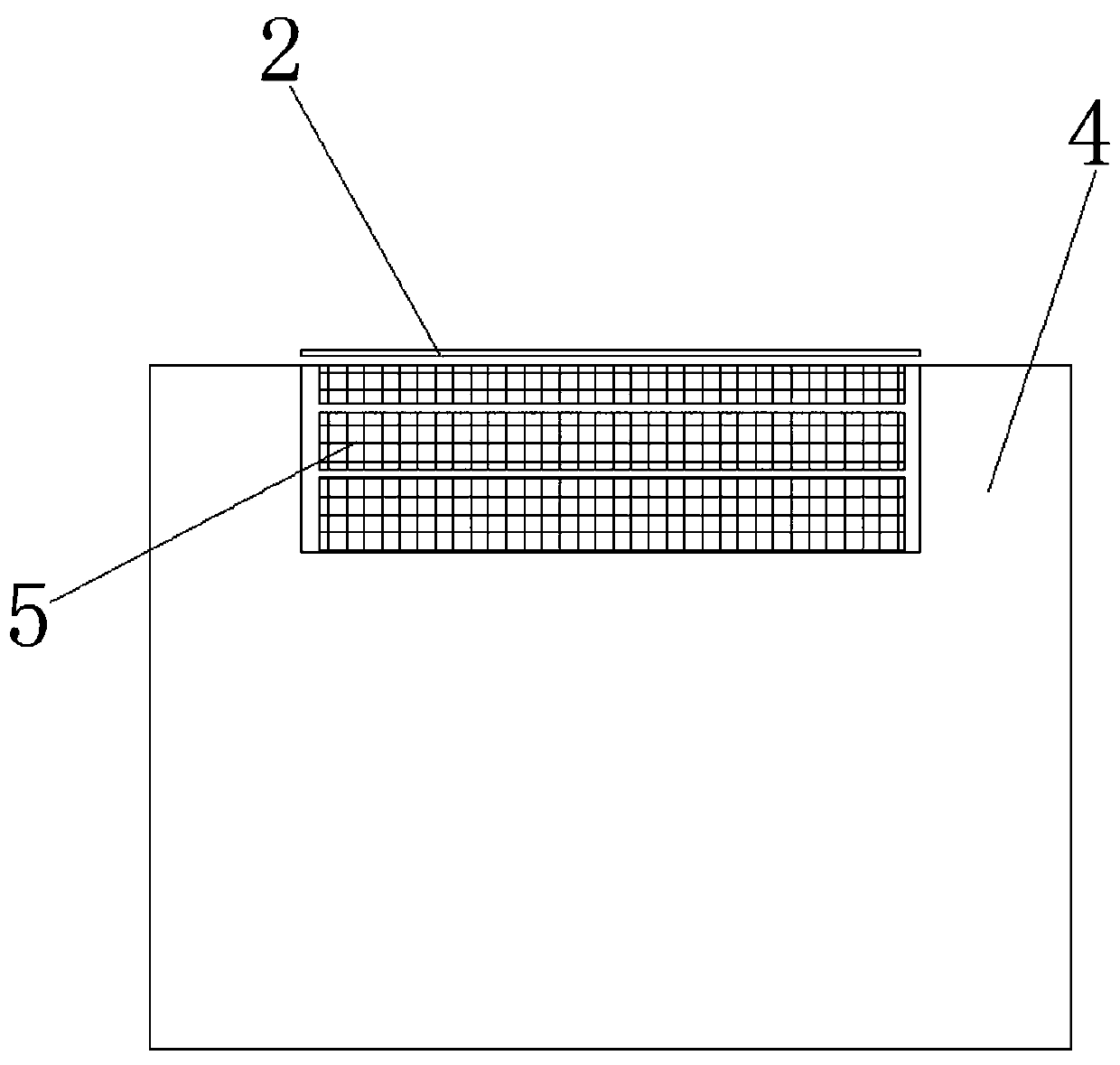

[0033] 1) Screen printing: use the screen plate 102 of the screen printing machine 1 to print multi-layer magnetic ink pigments 3 on the paper substrate 2, that is, place the paper substrate 2 to be printed on the screen printing table 101, and place the square The screen plate 102 is pressed down onto the paper substrate 2, and after the multi-layered magnetic ink pigment 3 is painted on the screen plate 102 with the squeegee 103, the multi-layered magnetic ink pigment 3 penetrates through the passage on the screen plate 102. The penetrating portion forms a print 104 onto the paper substrate 2 .

[0034] Multi-layer magnetic ink pigment 3 is mainly composed of strong magnetic ink pigment (pigment, material), filler, binder, and additional material. The multi-layer magnetic ink pigment 3 needs to have a residual magnetism of 0.15 and a coercive force of 16KA / M, the ...

Embodiment 2

[0042] A method for producing a layered magnetic brilliance diffusion effect, comprising the following steps:

[0043] 1) Screen printing: use the screen plate 102 of the screen printing machine 1 to print multi-layer magnetic ink pigments 3 on the paper substrate 2, that is, place the paper substrate 2 to be printed on the screen printing table 101, and place the square The screen plate 102 is pressed down onto the paper substrate 2, and after the multi-layered magnetic ink pigment 3 is painted on the screen plate 102 with the squeegee 103, the multi-layered magnetic ink pigment 3 penetrates through the passage on the screen plate 102. The penetrating portion forms a print 104 onto the paper substrate 2 .

[0044] Multi-layer magnetic ink pigment 3 is mainly composed of strong magnetic ink pigment (pigment, material), filler, binder, and additional material. The multi-layer magnetic ink pigment 3 needs to have a residual magnetism of 0.2 and a coercive force of 20KA / M, the m...

Embodiment 3

[0051] 1) Screen printing: use the screen plate 102 of the screen printing machine 1 to print multi-layer magnetic ink pigments 3 on the paper substrate 2, that is, place the paper substrate 2 to be printed on the screen printing table 101, and place the square The screen plate 102 is pressed down onto the paper substrate 2, and after the multi-layered magnetic ink pigment 3 is painted on the screen plate 102 with the squeegee 103, the multi-layered magnetic ink pigment 3 penetrates through the passage on the screen plate 102. The penetrating portion forms a print 104 onto the paper substrate 2 .

[0052] Multi-layer magnetic ink pigment 3 is mainly composed of strong magnetic ink pigment (pigment, material), filler, binder, and additional material. The multi-layer magnetic ink pigment 3 needs to have a residual magnetism of 0.4 and a coercive force of 32KA / M, the maximum particle diameter of the magnetic ink pigment is 10µm, and the ultraviolet absorber is 3%.

[0053] 2) Ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com